Dusting machine for chemical laboratory

一种化学实验室、除尘机的技术,应用在机器部件、清洁机械、清扫地毯等方向,能够解决刚性支撑性能差、自动化程度低、工作效率低下等问题,达到刚性支撑性好、工作效率高、除尘速度快的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

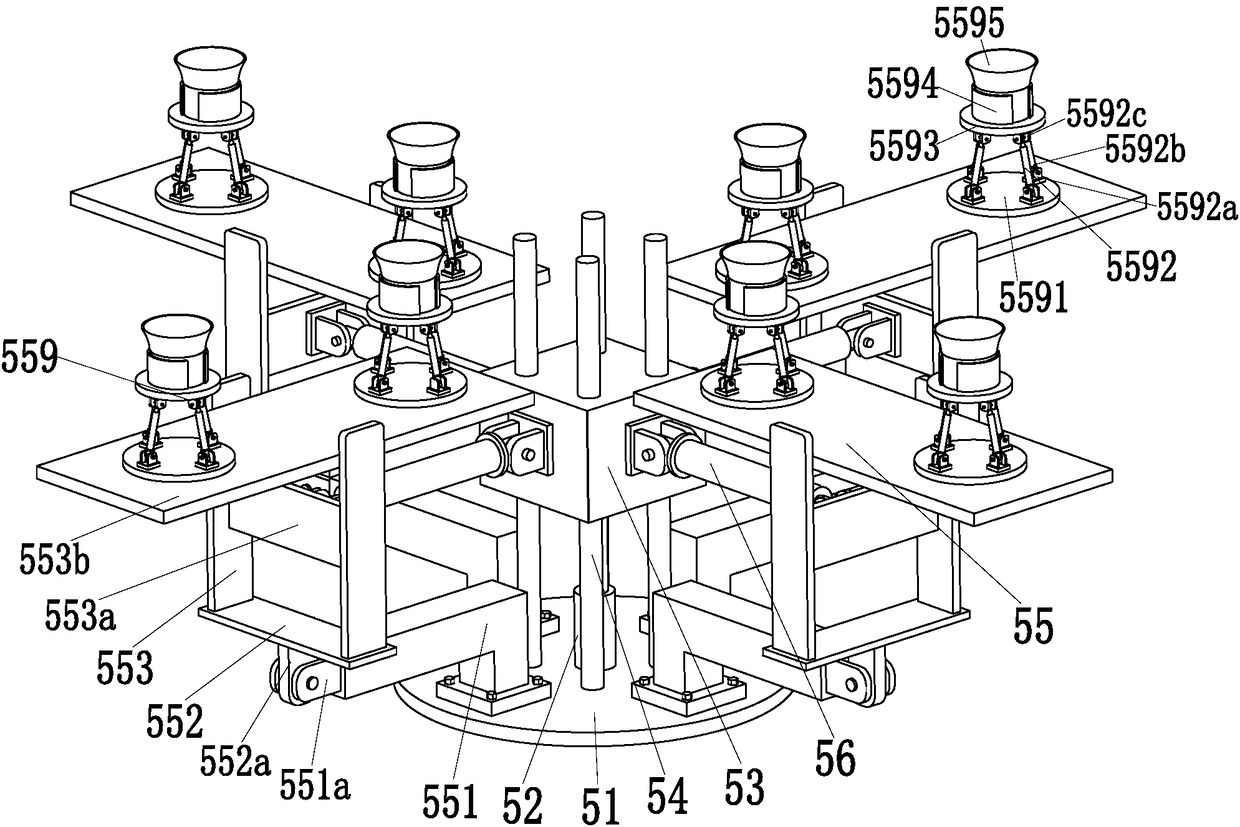

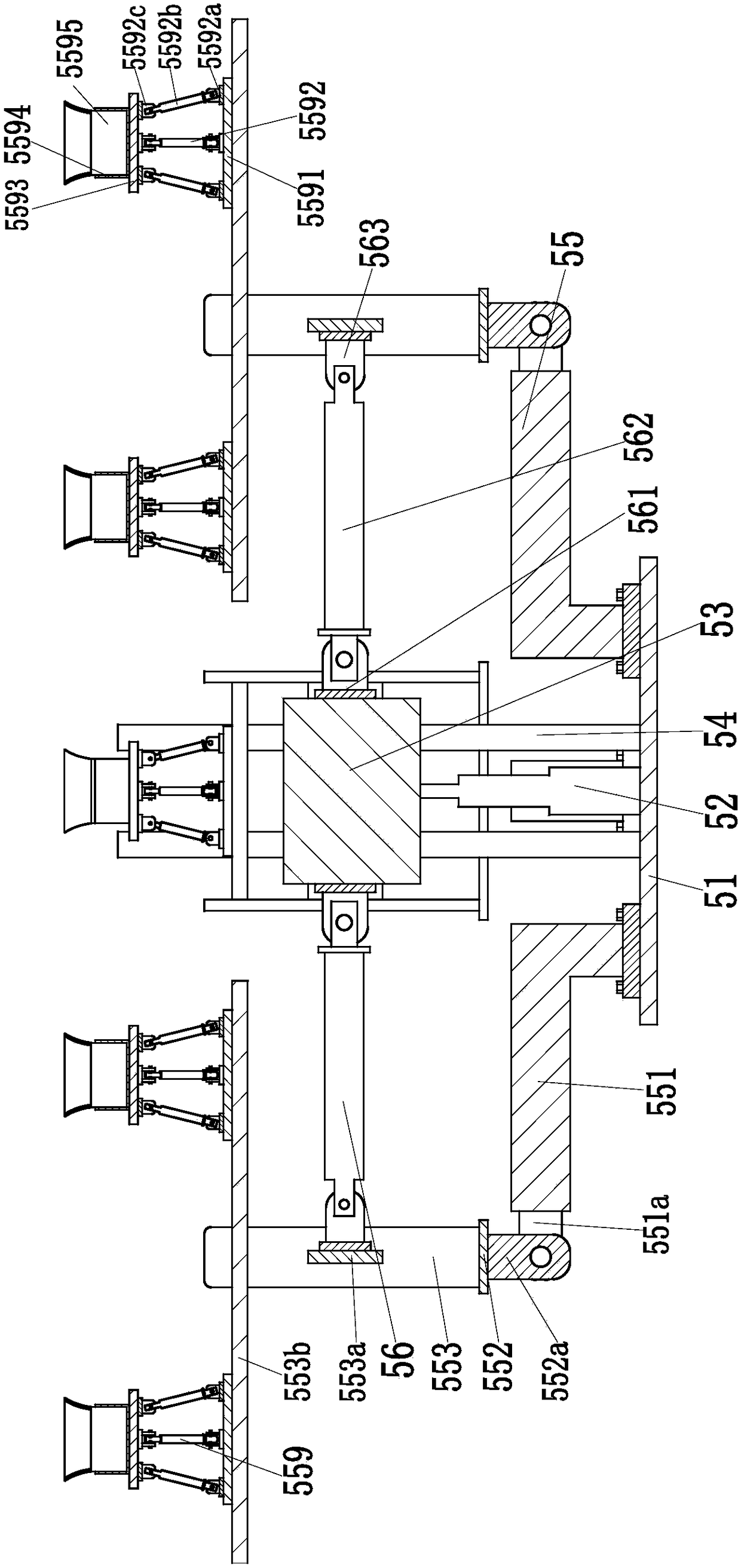

[0016] like figure 1 and figure 2As shown, a chemical laboratory dust remover includes a supporting round table 51, a No. 5 hydraulic cylinder 52 is installed in the middle of the upper end surface of the supporting round table 51, and a square adjustment block 53 is installed on the top of the No. 5 hydraulic cylinder 52. The square adjustment block 53 is symmetrically provided with four limit holes, and four positioning round rods 54 are symmetrically welded on the upper end surface of the support round table 51, and the four positioning round rods 54 are respectively installed on the four limit holes of the square adjustment block 53 , the four positioning round rods 54 play the role of limiting the movement direction of the square adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com