Droplet jetting 3D printing length dimension prediction method

A technology of droplet jetting and 3D printing, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., and can solve the problem that the size of droplet jetting 3D printing cannot be measured online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

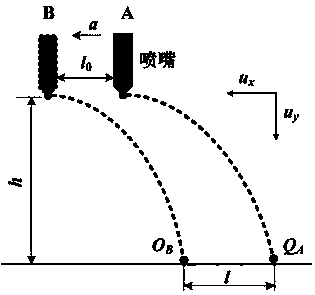

[0026] Use Flow 3D simulation software to simulate the process of printing a straight line. In the simulation, the initial temperature of the printing fluid material is set to 363K, and the initial temperature of the air and the printed layer material (or substrate) is 293K. The vertical distance of droplet falling is h=1.7mm, and the printing frequency f=70Hz.

[0027] Firstly, a single droplet ejection and solidification simulation is carried out, so that the single droplet is at the initial horizontal velocity u x =0.03m / s Spray onto the substrate to solidify and form until it is completely solidified (t=0.33s). The simulation results are processed by post-processing software, and the diameter of a single droplet after solidification is D=420um.

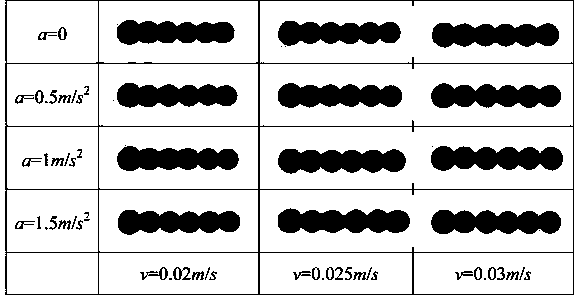

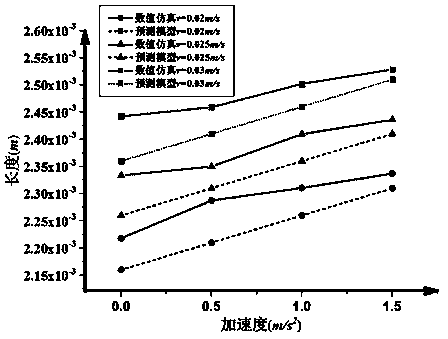

[0028] To further study the situation of printing straight lines, in order not to lose generality, the parameters that have been set when printing a single droplet are not changed, but considering the influence of nozzle movement...

Embodiment 2

[0032] The actual printing is carried out according to the three steps described in the specific implementation method, and the low-melting-point tin-bismuth alloy material is selected, and the melting point is 65 degrees Celsius. Firstly, the dropletability test printing of the molten liquid is carried out with the printing vertical distance h=2mm, and the diameter of a single droplet after solidification is measured D=490um, and the initial velocity in the vertical direction of the droplet when it leaves the nozzle is u y = 1 m / s (acquire the speed with a high-speed camera). Then keep at the level of the vertical distance, keep the pressure, material temperature and other parameters during the trial printing unchanged, and control the nozzle at the initial speed u x =0.003m / s, acceleration a=0.001m / s 2 Do horizontal linear motion, at the same time, set the printing frequency f=7Hz and start printing 8 drops continuously, the result is as follows Figure 4 shown. Measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com