A Traceable Liquid Hazardous Waste Safe Unloading System

A hazardous waste, traceable technology, applied in packaging, large containers, transportation and packaging, etc., can solve the problems of insufficient protection level, low processing efficiency, non-classification, etc., to reduce the probability of unloading errors, save manpower and time, Effects without manual recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

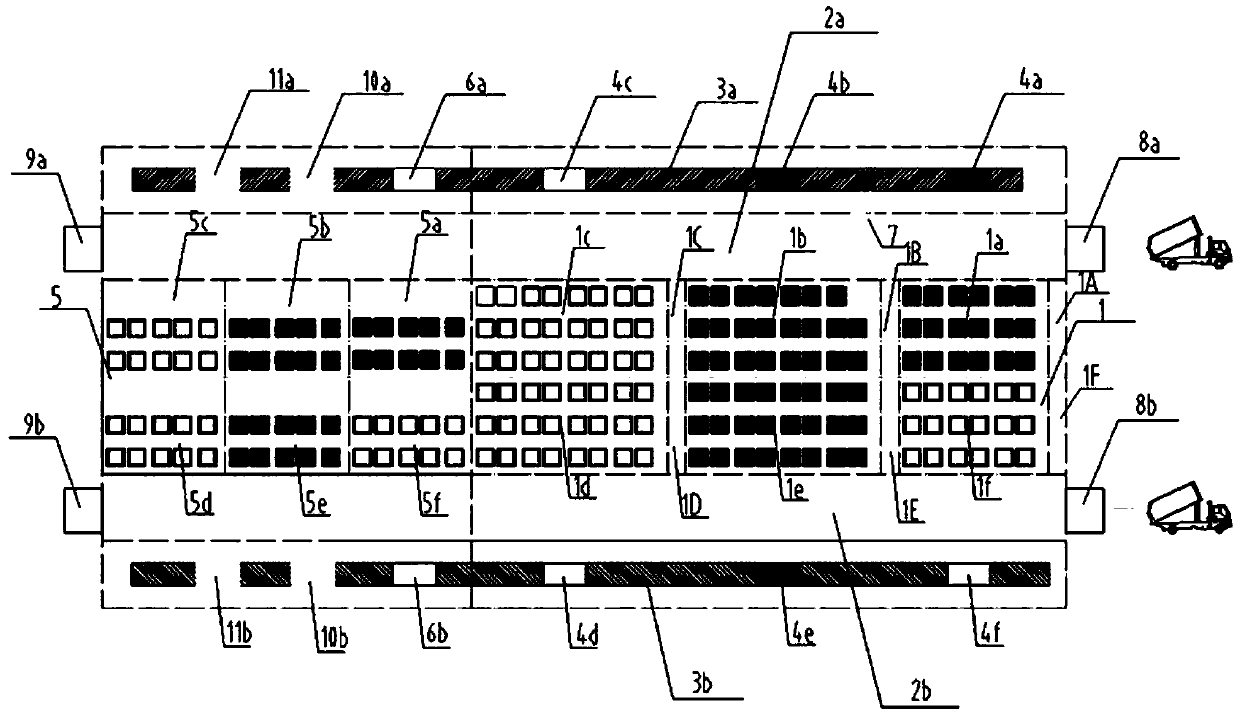

[0062] In the following embodiments, an unloading workshop is taken as an example to further illustrate the technical solution of the present invention.

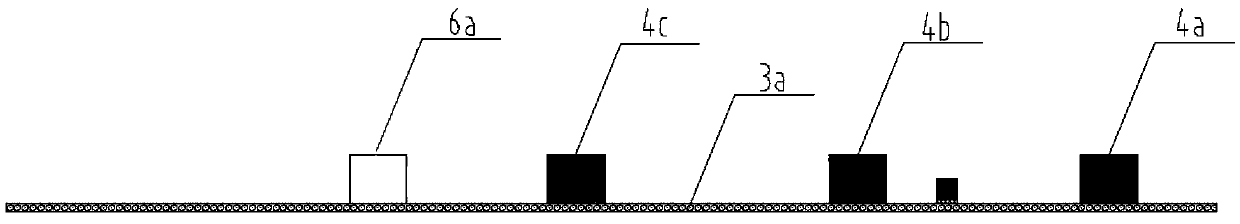

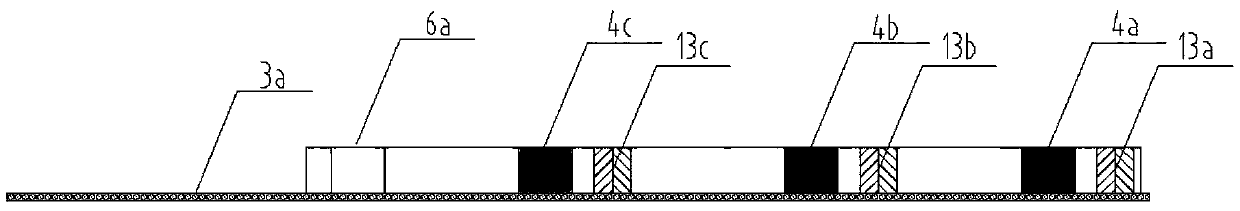

[0063] The area of the embodiment is a rectangular factory building with two inlets 8a, 8b at one end and two outlets 9a, 9b at the other end. The plant mainly processes six types of liquid hazardous waste, namely a, b, c, d, e, and f. These six types of hazardous waste correspond to material barrels of 6 colors. The material barrels in this embodiment are tonnage barrels , the six types of hazardous liquid wastes can correspond to the six types of acidic material storage tanks, alkaline material storage tanks, and neutral material storage tanks according to their physical and chemical properties, respectively corresponding to the six discharges on the conveyor belts 3a and 3b. Area.

[0064] The material temporary storage area 1 is set in a part of the area between the entrance and the exit. In a long and narrow area clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com