An exposure machine which is easy to maintain

A technology for exposure machines and exposure lamps, applied in the field of exposure machines, can solve the problems of inconvenient movement, lack of replacement of damaged LED lights, lack of storage functions for spare light racks, etc., and achieve the effects of convenient identification and classification and improved anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

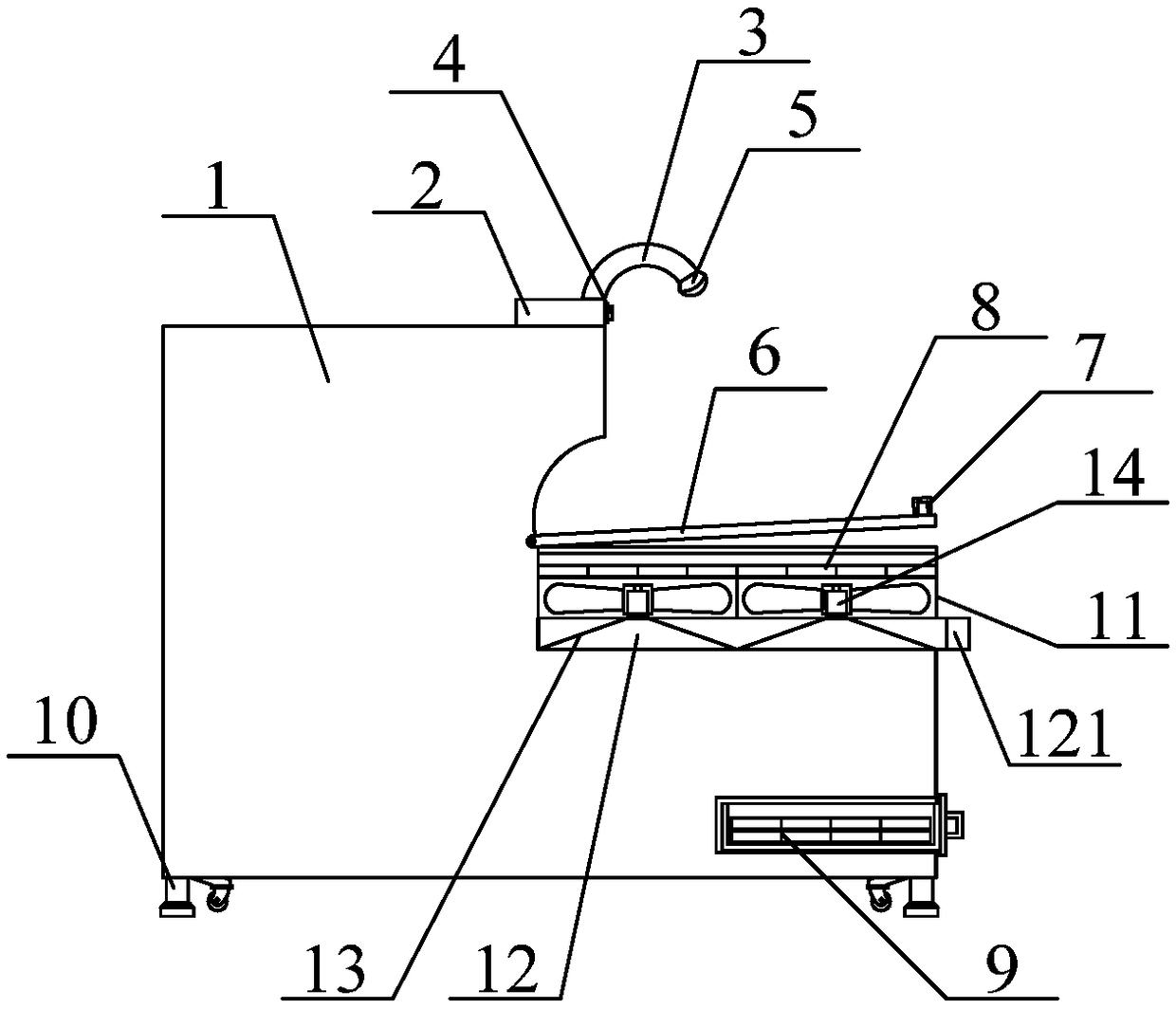

[0034] as attached figure 1 And attached figure 2 shown

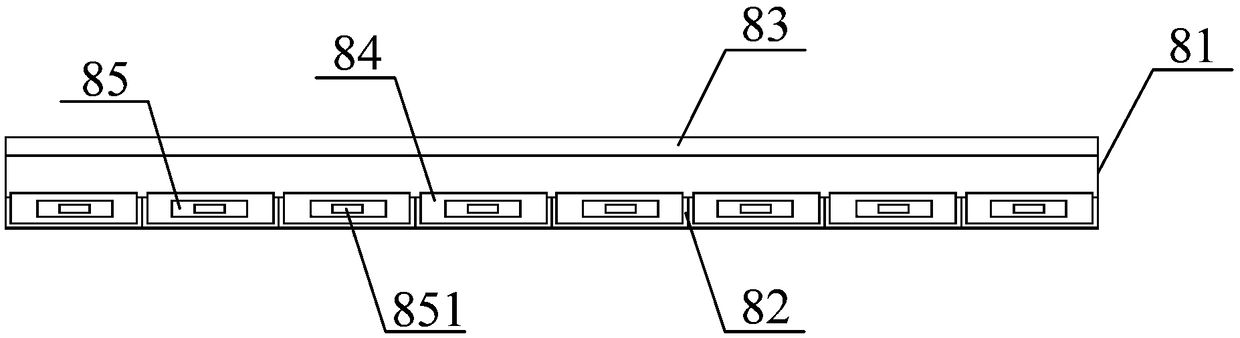

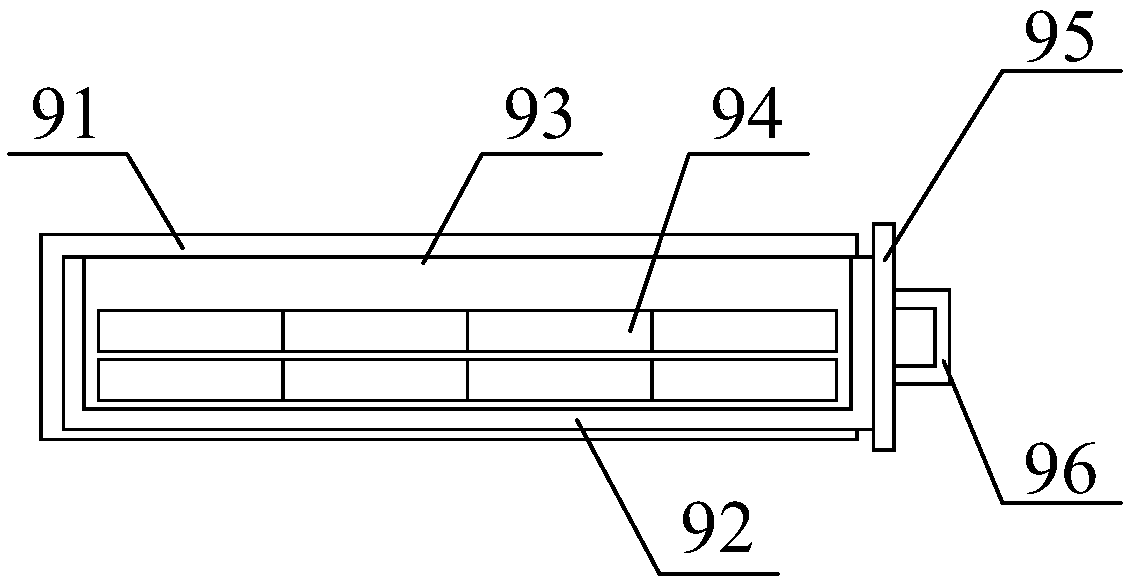

[0035]The present invention provides an exposure machine that is easy to maintain, including an exposure machine shell 1, a storage battery 2, an adjustable hose 3, a power switch 4, an auxiliary lighting lamp 5, a machine cover 6, a handle 7, and a replaceable exposure lamp frame structure 8. Spare exposure lamp rack storage frame structure 9, adjustable bottom frame structure 10, fixed outer frame 11, air duct 12, fan bracket 13 and miniature axial flow fan 14, the battery 2 is glued to the exposure machine shell 1; the adjustable hose 3 is glued to the upper right side of the battery 2; the power switch 4 is glued to the right side of the battery 2; the auxiliary lighting 5 is glued to the adjustable soft the right end of the tube 3; the cover 6 is axially connected to the upper right side of the exposure machine housing 1; the handle 7 is glued to the upper right side of the cover 6; the replaceable light frame s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com