Vehicle sound insulation pad coiling device

A technology of automotive sound insulation pads and rolls, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of poor versatility of winding devices and high equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

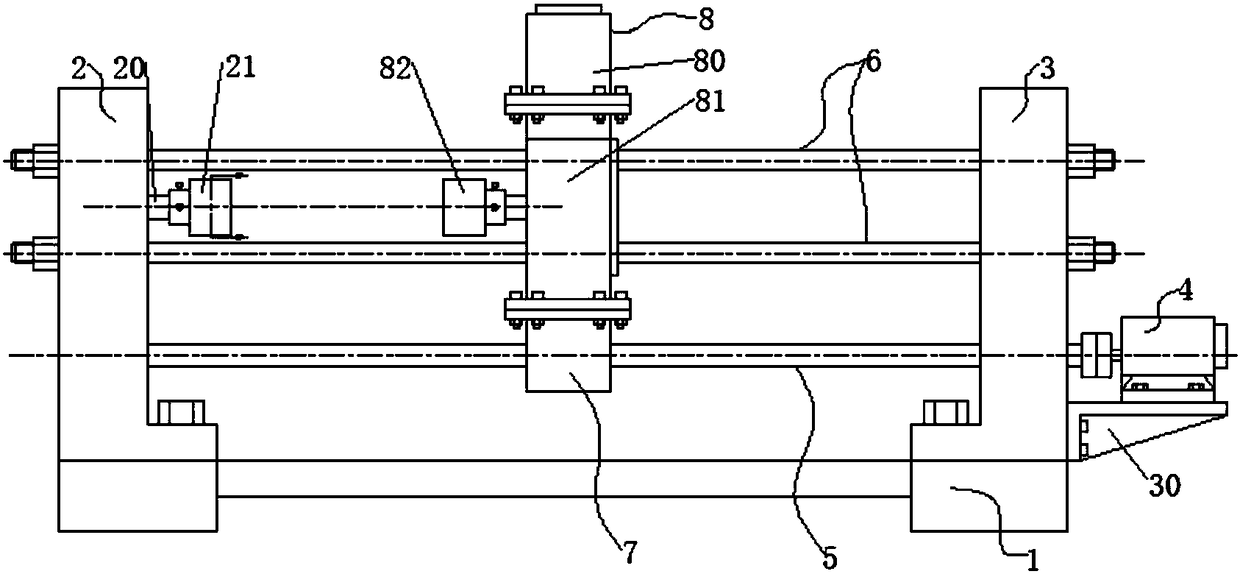

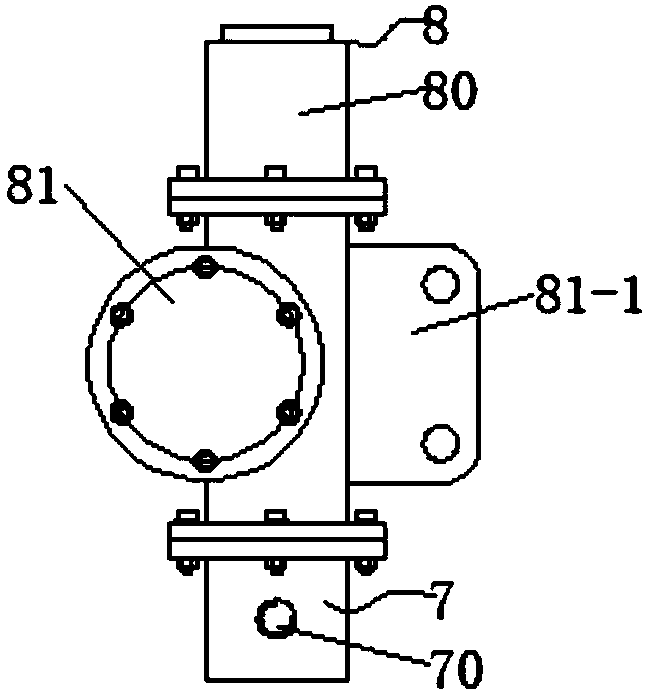

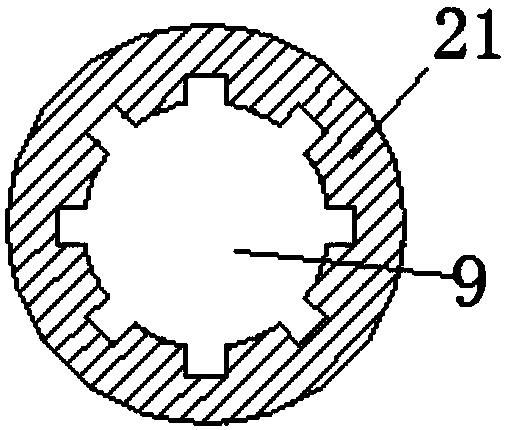

[0028] The car sound insulation mat rolling device is aimed at the rolling operation of car sound insulation mats with different widths. First, one end of the winding shaft is inserted into the spline hole 9 in the sleeve one 21, and then the servo motor 4 is started, and the servo motor 4 passes through the joint. The shaft device drives the screw mandrel 5 to rotate, because the drive block 7 is provided with a threaded hole 70, the drive block 7 forms a spiral pair connection with the screw mandrel 5 through the threaded hole 70, and the winding device 8 is composed of a motor 80, a speed reducer 81 Composed of sleeve two 82, the lower end of the reducer 81 is fastened to the drive block 7 through bolts, the motor 80 is connected to the upper end of the reducer 81 by bolts, and the second sleeve 82 is connected to the output shaft of the reducer 81 , so the screw mandrel 5 rotates and drives the driving block 7 to move together with the winding device 8, so that the guide ho...

Embodiment 2

[0030] On the basis of Embodiment 1, the following improvements are made: the rear end of the housing of the reducer 81 is provided with a guide seat 81-1, and the guide seat 81-1 is provided with two guide holes 81-10, And the guide rod 6 passes through the guide hole 81-10, so that the winding device 8 runs stably in the lateral direction. At the same time, the guide rod 6 is provided with two, and they are coplanar on the vertical plane, which ensures the bearing strength of the winding device 8 ; The reducer 81 is a worm gear reducer with a self-locking function, and the rewinding action is safe, and the rewinding shaft will not be reversed due to the offset of the center of gravity of the rolled automobile sound insulation mat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com