Salt pan plastic tarpaulin injection device sliding way system

A kind of technology of plastic thatch and slideway, applied in the direction of alkali metal chloride, etc., to achieve the effect of reducing cost, saving manpower and material resources, and good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

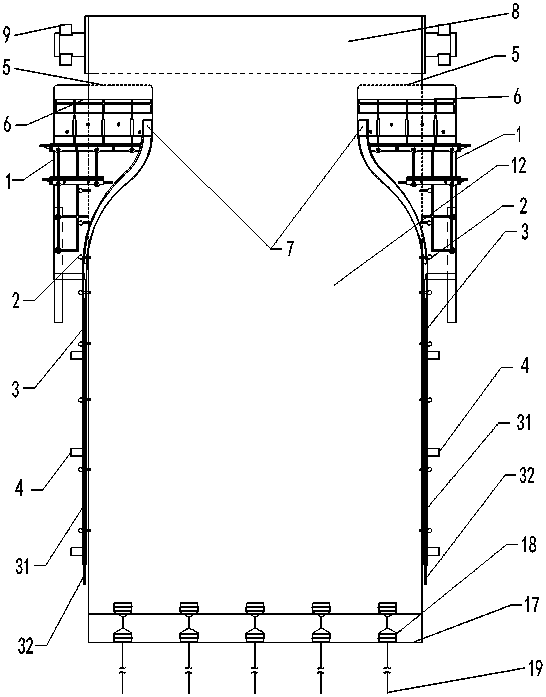

[0043] Example: see Figure 1-11 , Yantian plastic thatch track system, including a floating reel 8, the two ends of the floating reel 8 are respectively rotated and connected to the symmetrically arranged floating reel bracket 9, and the plastic thatch 12 is wound on the floating reel 8, and the floating reel The side of the cylinder 8 close to both ends is respectively equipped with symmetrically arranged rail-entry devices, and the side of the rail-entry device far away from the floating drum 8 is provided with a rail device, and the plastic tarpaulin 12 is pulled by the driving device and passed through the rail-entry device and the rail in turn. The device covers the salt pan.

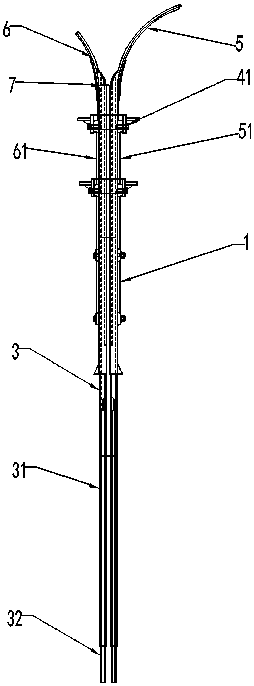

[0044] The orbiting device includes symmetrically arranged orbiting device assemblies 1 installed on one side of the buoyant drum 8 near both ends.

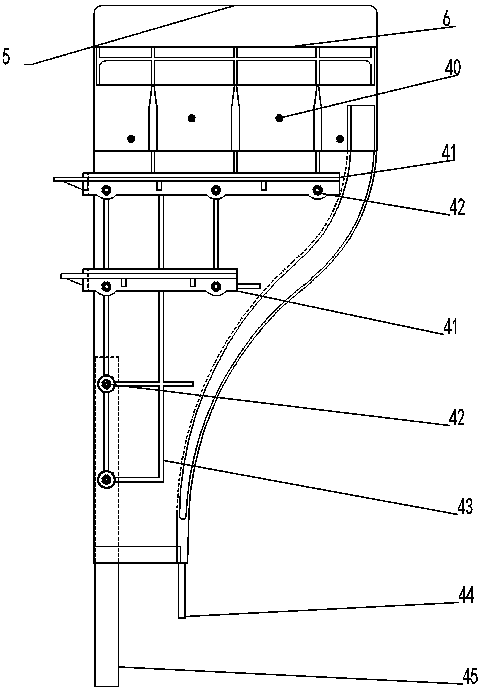

[0045] The rail entry device assembly 1 includes two vertically symmetrical rear end plates 51 of the slideway into the rail and a rear end plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com