Oil extraction auxiliary conveying equipment

A technology of oil extraction and transportation equipment, which is applied in the direction of extraction fluid, earthwork drilling, measurement, etc., and can solve problems such as pipeline blockage, easy cleaning that cannot be cleaned in time, and reduced oil extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

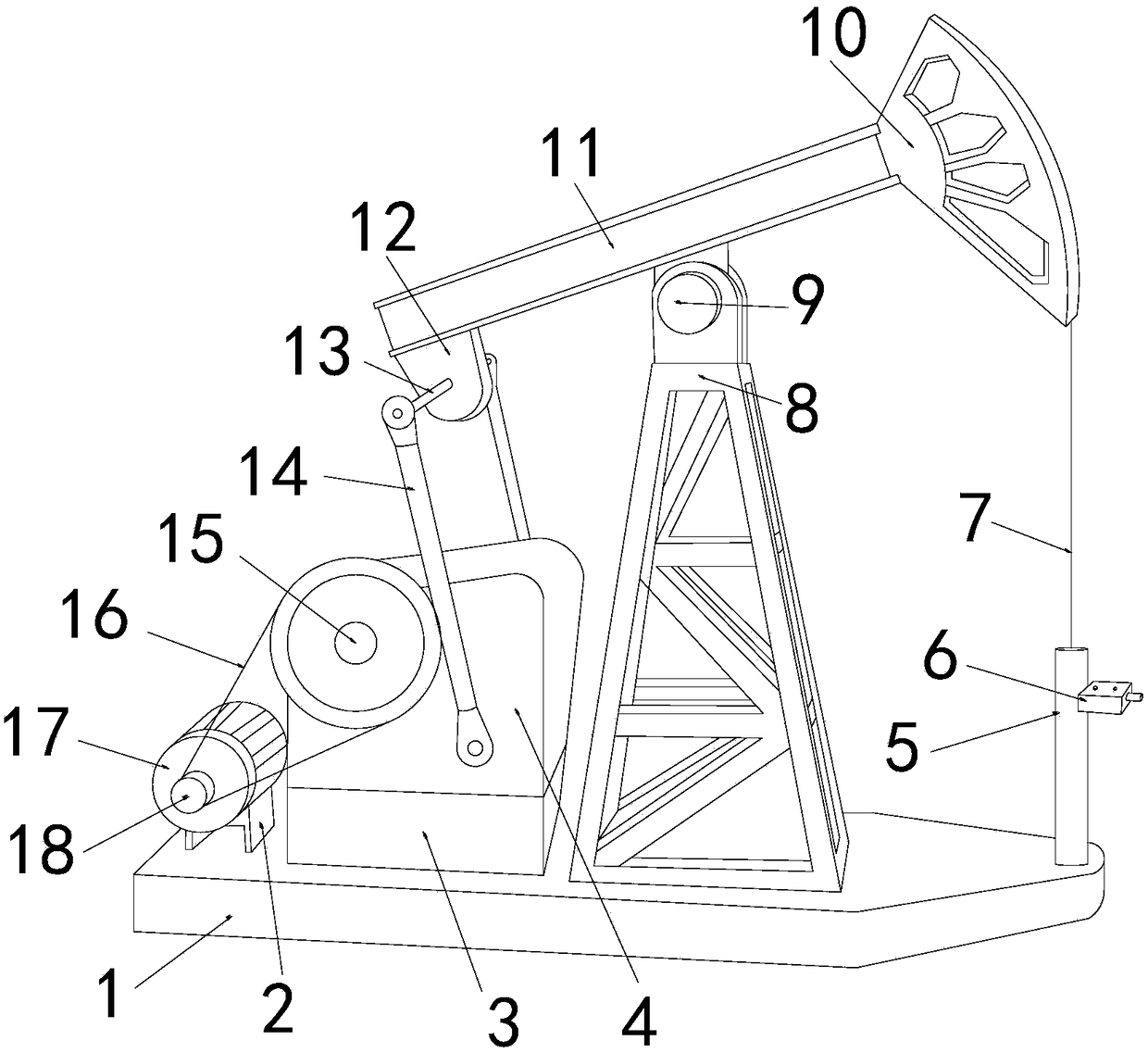

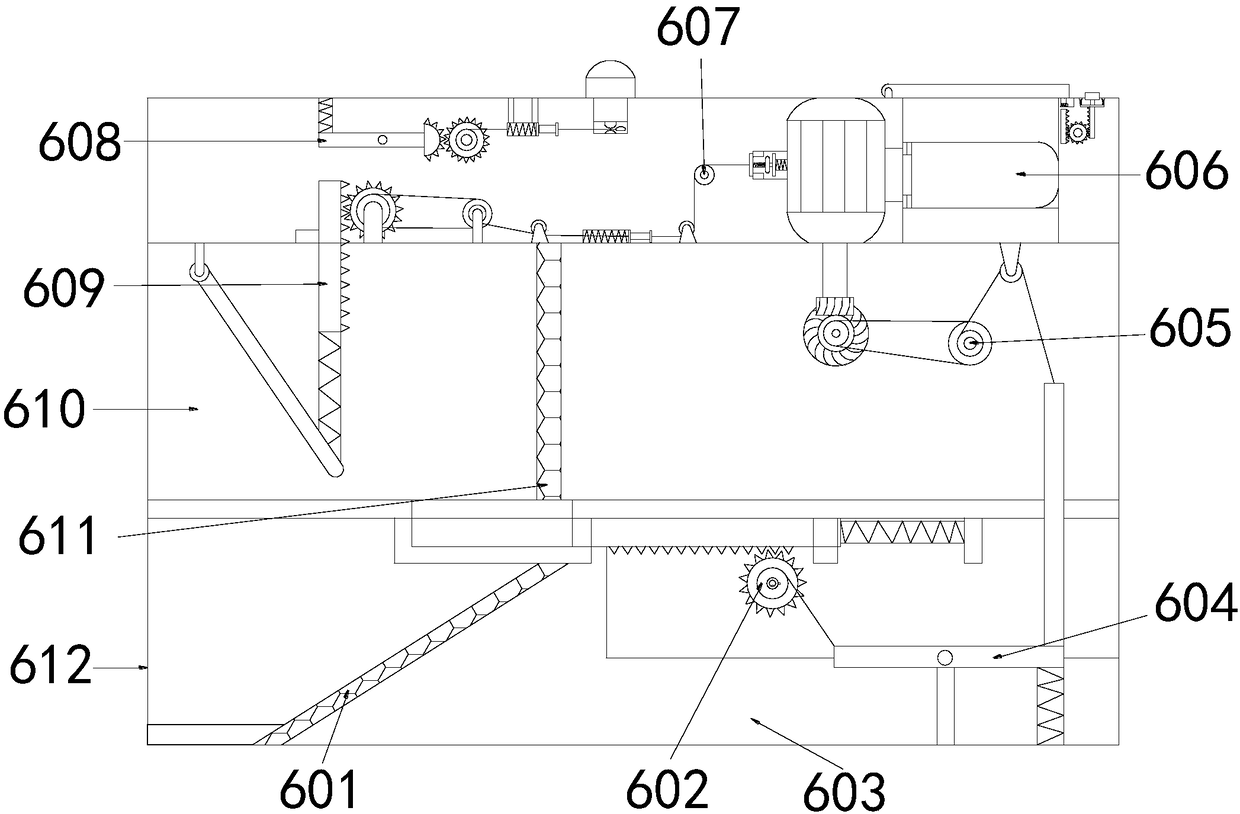

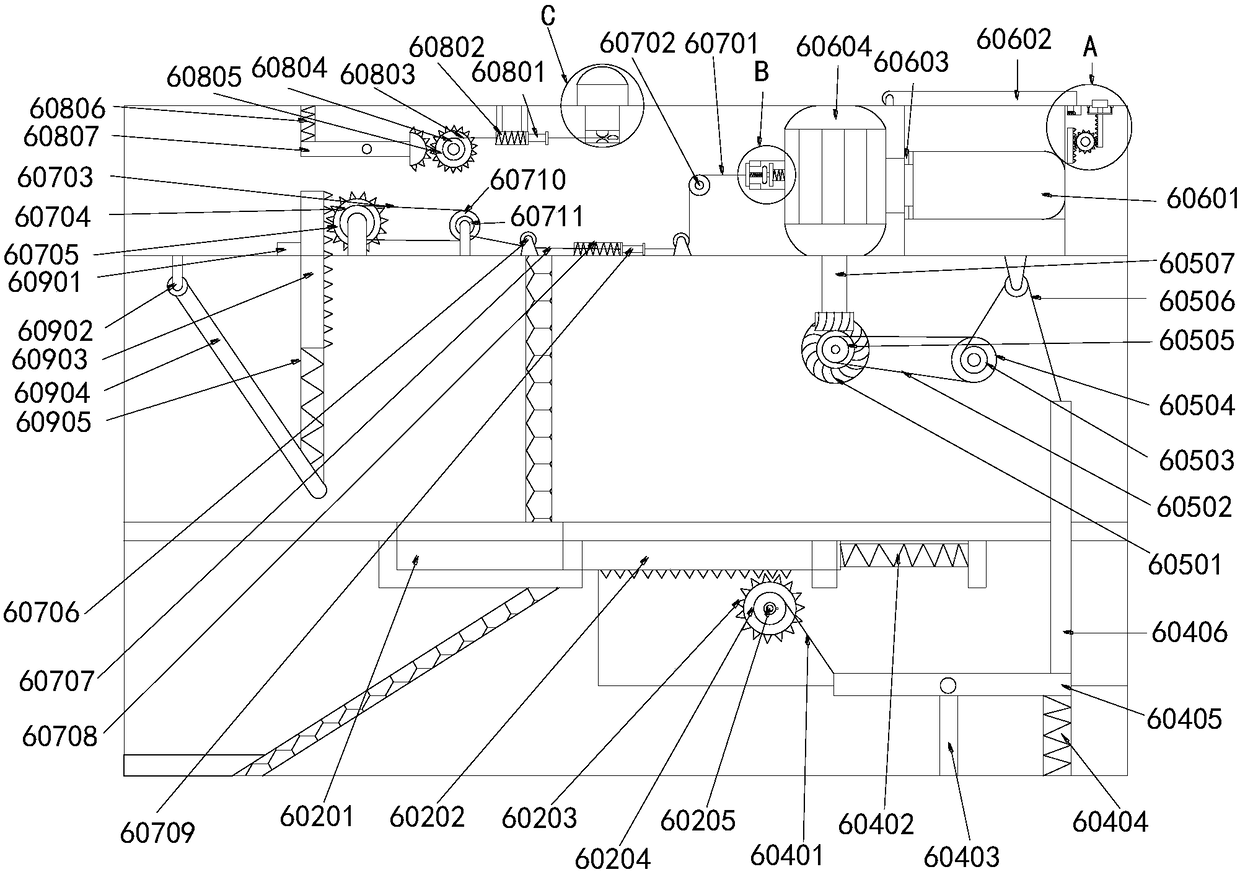

[0024] see Figure 1-Figure 6, the present invention provides a technical solution for auxiliary transportation equipment for oil exploitation: its structure includes a base 1, a base 2, a base 3, a reduction box 4, an oil pipe 5, a detector 6, a stay rope 7, a bracket 8, central axis 9, donkey head 10, beam 11, tail shaft 12, connecting rod 13, support rod 14, No. 1 transmission wheel 15, No. 1 transmission belt 16, motor 17, No. 2 transmission wheel 18, the No. 1 The base 2 is located at the left end of the top surface of the base 1, and is welded with the top surface of the base 1. The top surface is provided with a motor 17, which is an integrated structure with the bottom surface of the motor 17. One end of the motor 17 is provided with a No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com