Pipe buckle assembly and brushing water pipe fixing structure

A component and buckle technology, applied in the field of sanitary ware, can solve the problems of narrow operating space, long maintenance time, poor visibility, etc., achieve low rework rate, save time, and achieve easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments.

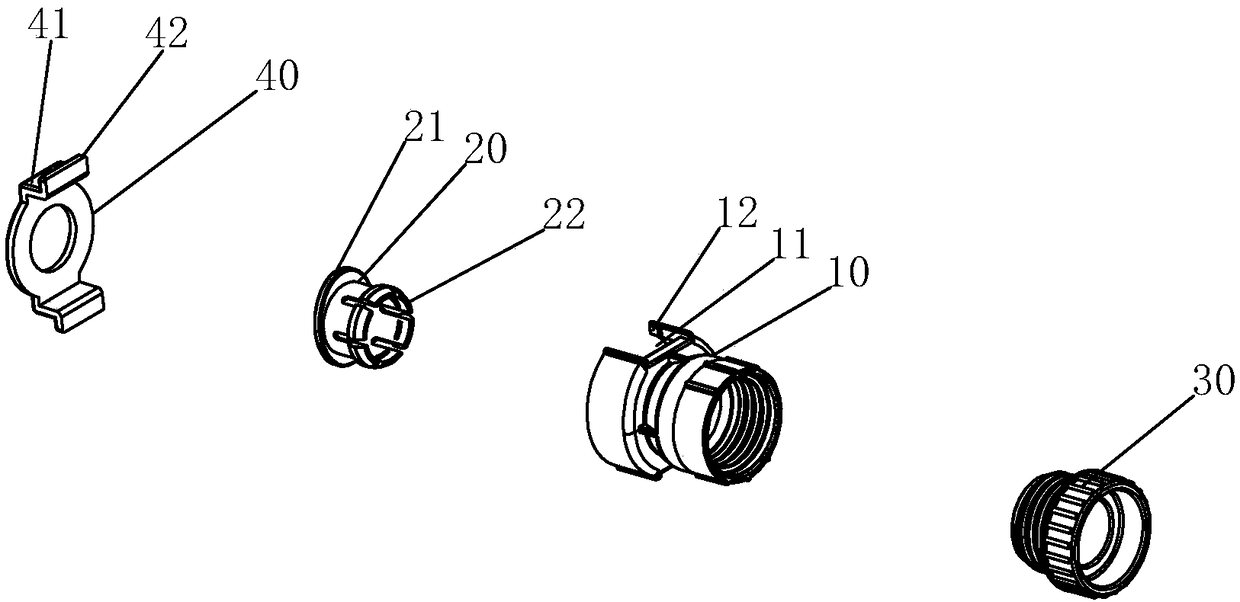

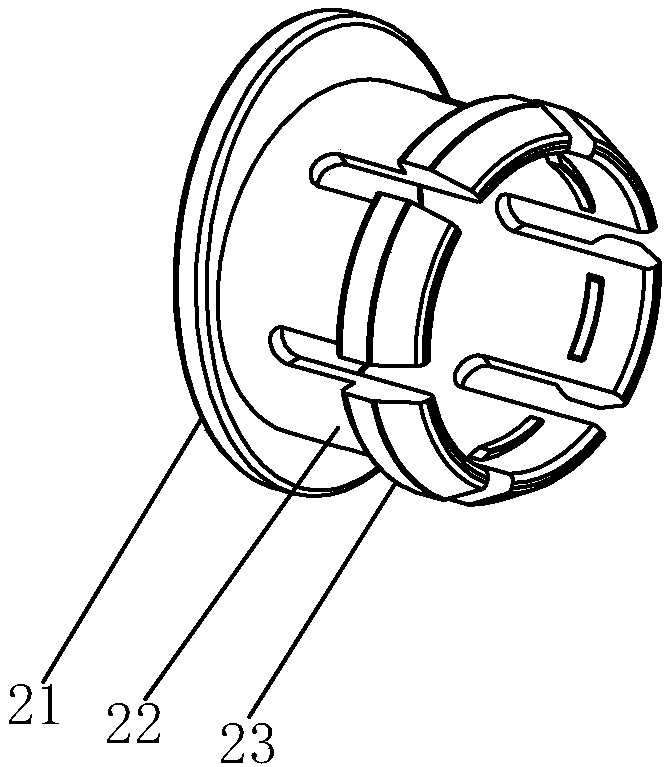

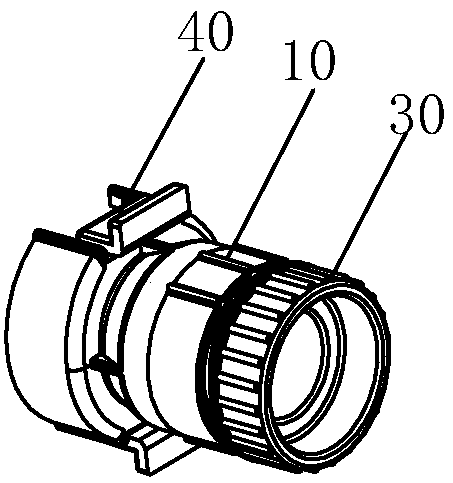

[0040] refer to Figure 1 to Figure 13 , a pipe buckle assembly for locking a pipe body 50, which mainly includes a locking member 20, a buckle body 10, a sleeve body 30, a pull buckle 40, and the like. The button body 10 is axially penetrated, one end is provided with an internal thread, and the other end is provided with two notches 11 , the notches 11 extend in the axial direction, and the ends of both side walls of the notches 11 are provided with stoppers 12 . The inner wall of the button body 10 is provided with an empty groove 13 close to the middle, and the end of the empty groove 13 opposite to the block 12 is provided with an extruding surface 14 . The extruding surface 14 is a conical surface or an inclined surface, and the inner diameter of one end close to the stopper 12 is smaller than the inner diameter of the other end. In addition, a stepped hole 15 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com