Litter collector for fresh collection and automatic degradation treatment and operation method of litter collector

An automatic degradation and litter technology, which is applied in the field of plant litter degradation tools, can solve the problems of experimental accuracy, cumbersome experimental design, and high research cost, and achieve the effects of convenient operation, good application value, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

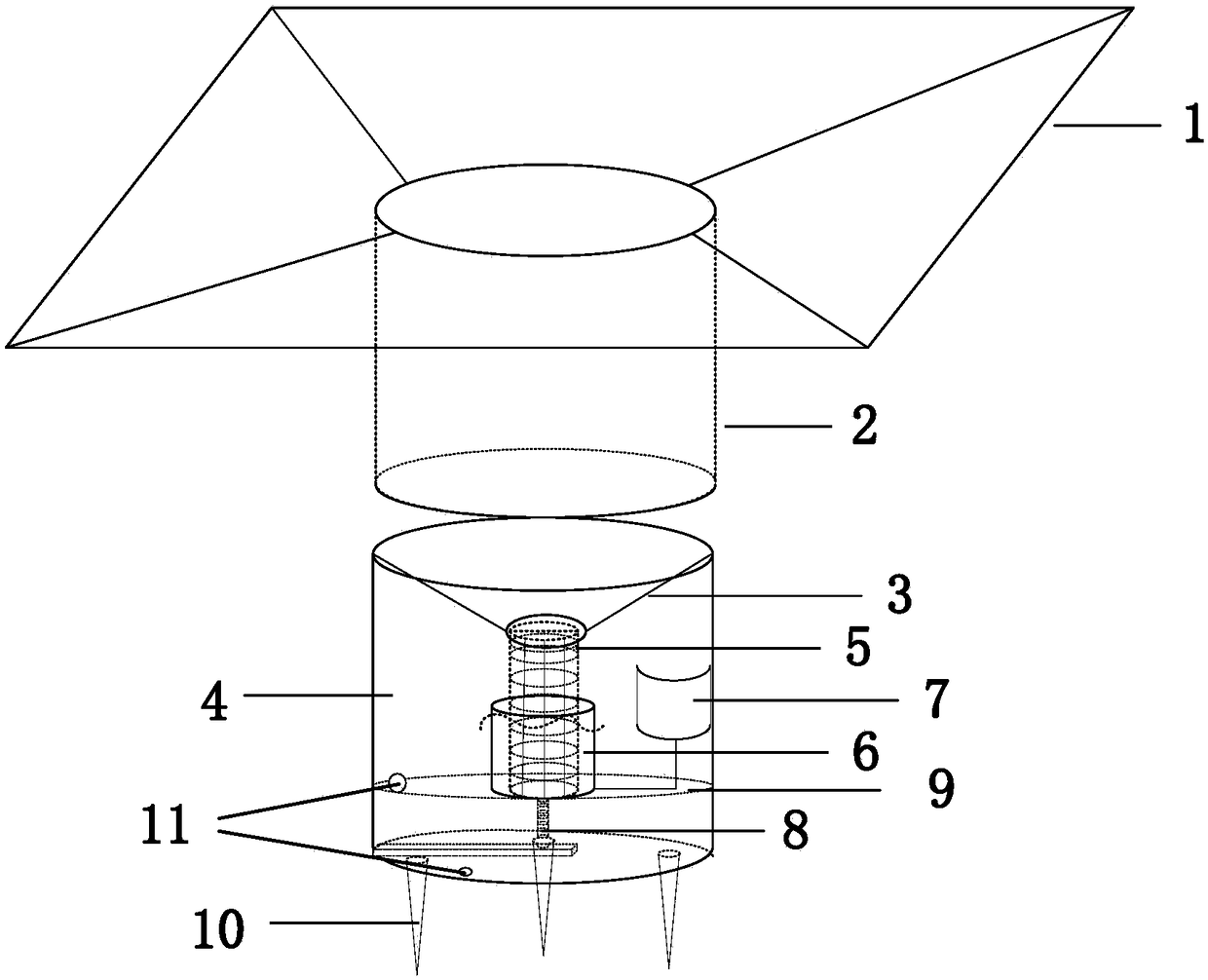

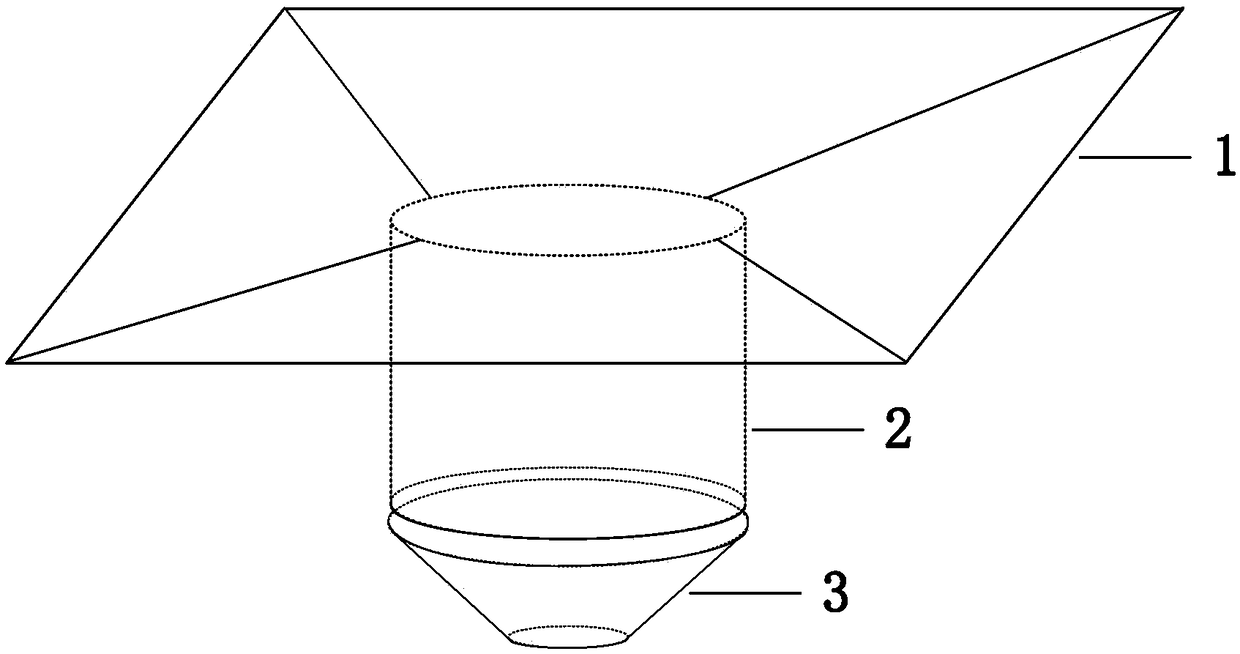

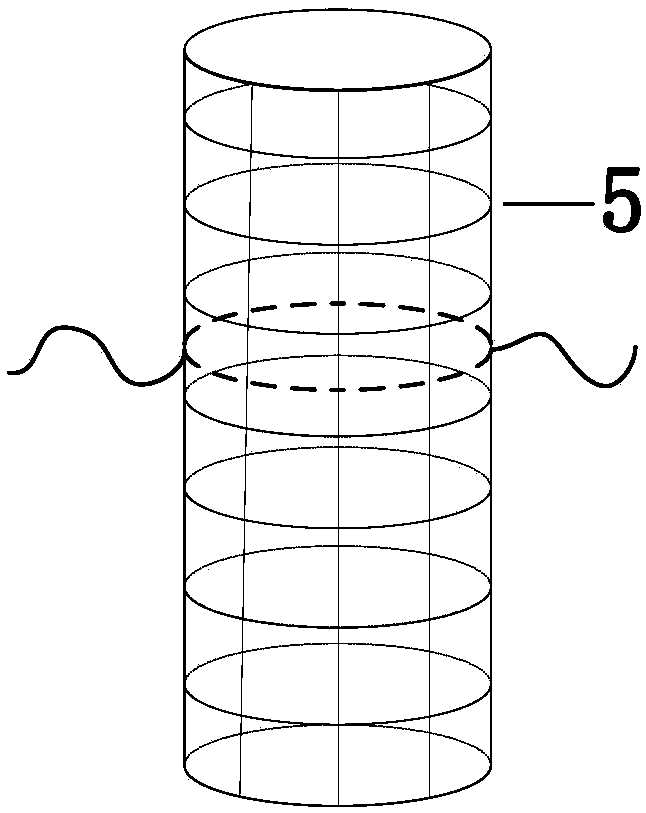

[0041] refer to Figure 1-Figure 5 , a litter collector for fresh collection and automatic degradation treatment, including an upper fresh litter collection device and a lower litter automatic degradation treatment device. Barrel type. The upper fresh litter collection device and the lower litter automatic degradation treatment device are fixedly connected together by nesting, and the middle part is loaded with a layered litter net bag 5 to form a complete litter collector;

[0042] The fresh litter collection device on the upper layer is composed of three parts: an anti-rust iron collecting plate 1, an upper anti-rust cylinder 2 and an anti-rust funnel 3;

[0043] The lower litter automatic degradation treatment device includes a lower rust-proof cylinder 4, a hollow litter fixing barrel 6, a dust inlet sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com