Mobile universal metallographic sample polishing fixture and its application method for clamping samples

A metallographic sample and mobile technology, which is applied in the field of polishing fixtures, can solve the problems of unfavorable microstructure observation and analysis, inability to achieve versatility, and inability to reuse, so as to achieve high-precision motion control and realize Portability and mobility, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

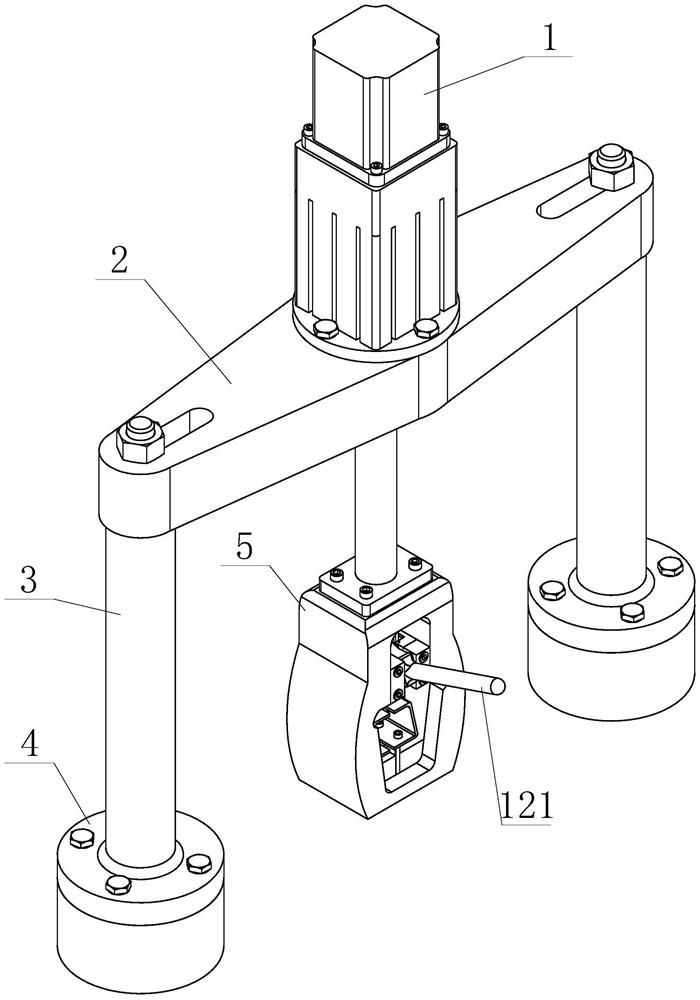

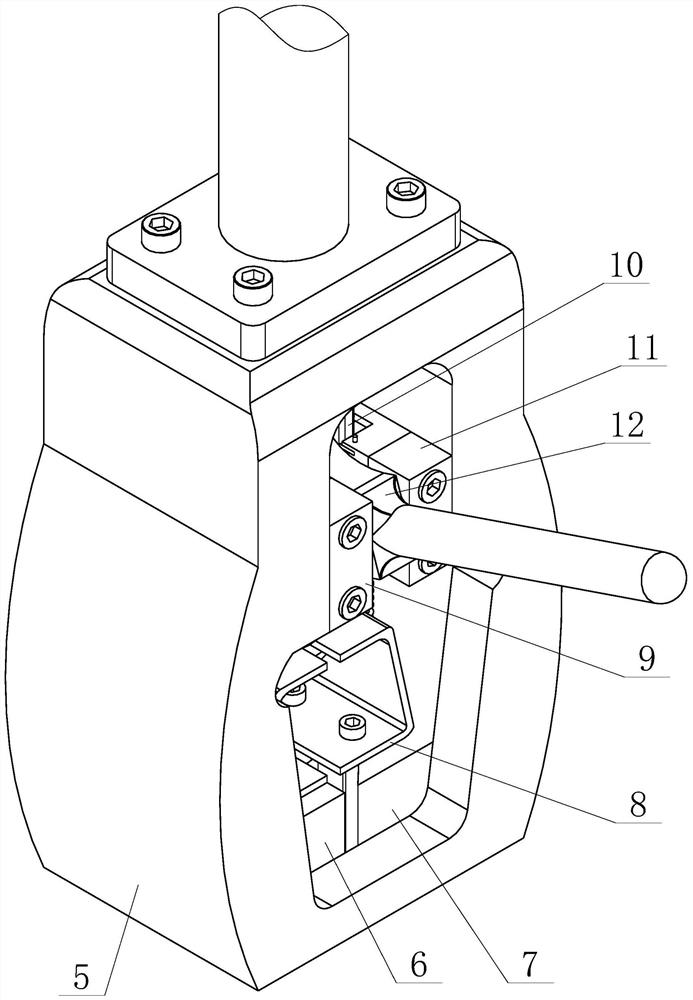

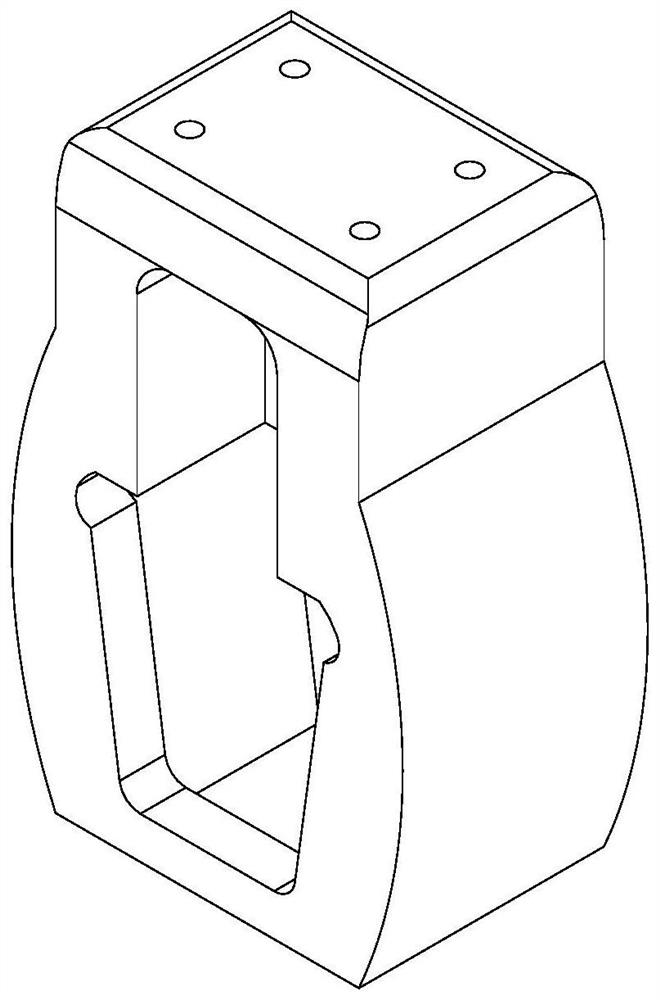

[0055] like figure 1 The mobile universal metallographic sample polishing fixture shown includes a "door"-shaped support frame and a polishing fixture body installed inside the "door"-shaped support frame and driven by the drive element 1 to translate up and down, wherein the "door" The glyph support frame is used to fix the specific position of the polishing clip; the driving element 1 is used to realize the vertical movement of the polishing clip, and the polishing clip is used to fasten the metallographic sample 14 and maintain the level of the metallographic sample 14 Spend.

[0056] like Figure 17 The shown "door"-shaped support frame includes a plate-like horizontal horizontal frame 2 and two supporting columns 3 respectively arranged at its two ends; The middle section of the horizontal frame 2 is provided with an installation through hole for fixing the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com