A miniature linear reciprocating friction and wear testing machine combined with in-situ observation of friction interface

A technology of friction and wear test and friction interface, which is applied in the direction of testing wear resistance, measuring devices, strength characteristics, etc., and can solve problems such as difficulty in applying lubrication, measurement error of friction coefficient, and large volume of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

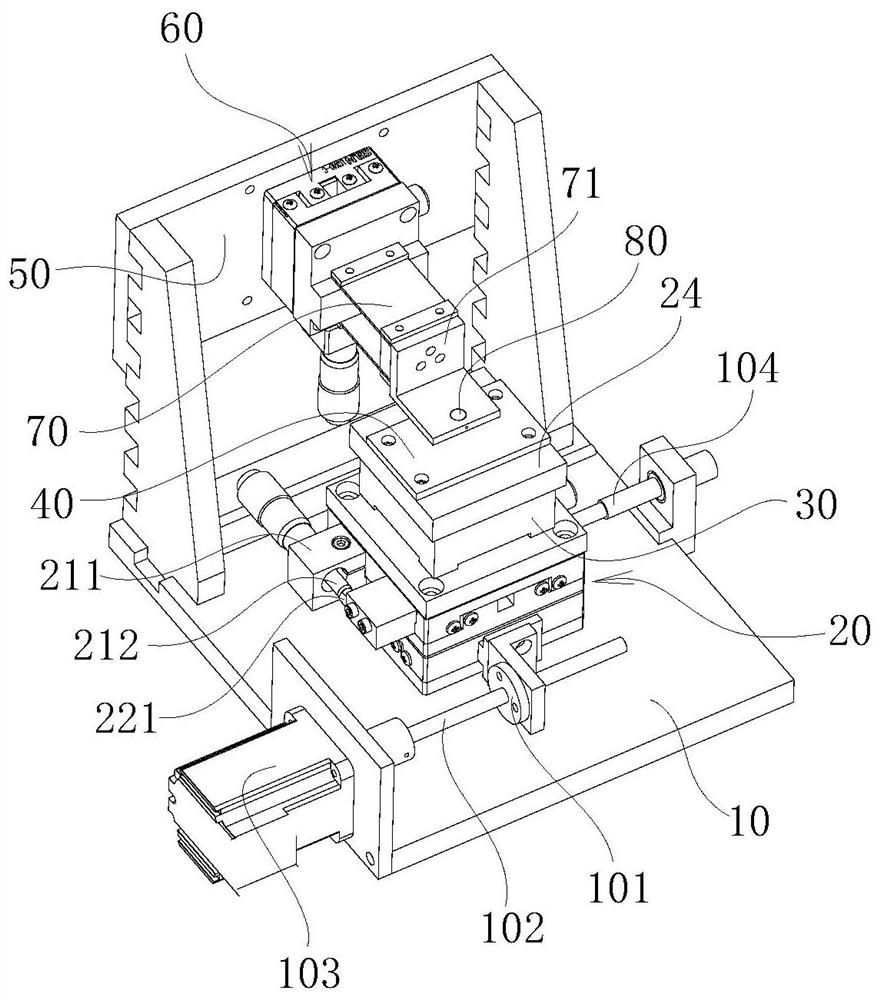

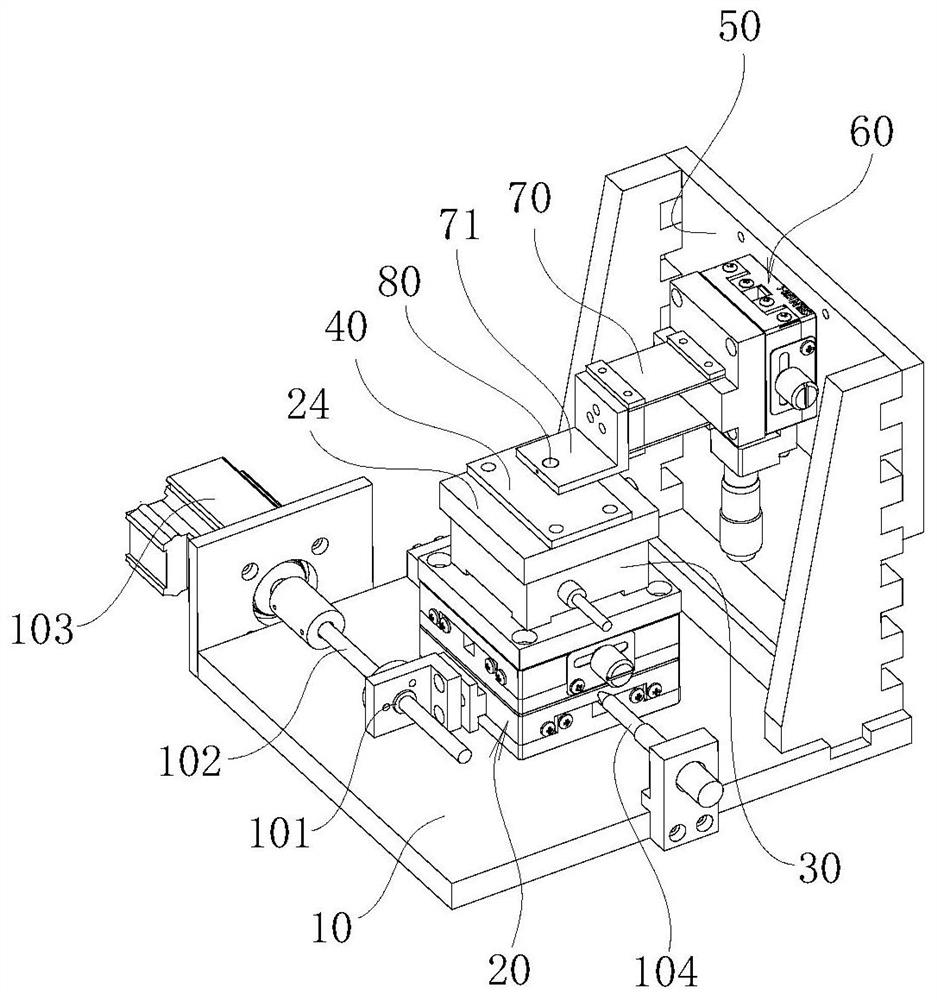

[0012] to combine Figure 1 to Figure 6 , the present invention is further described:

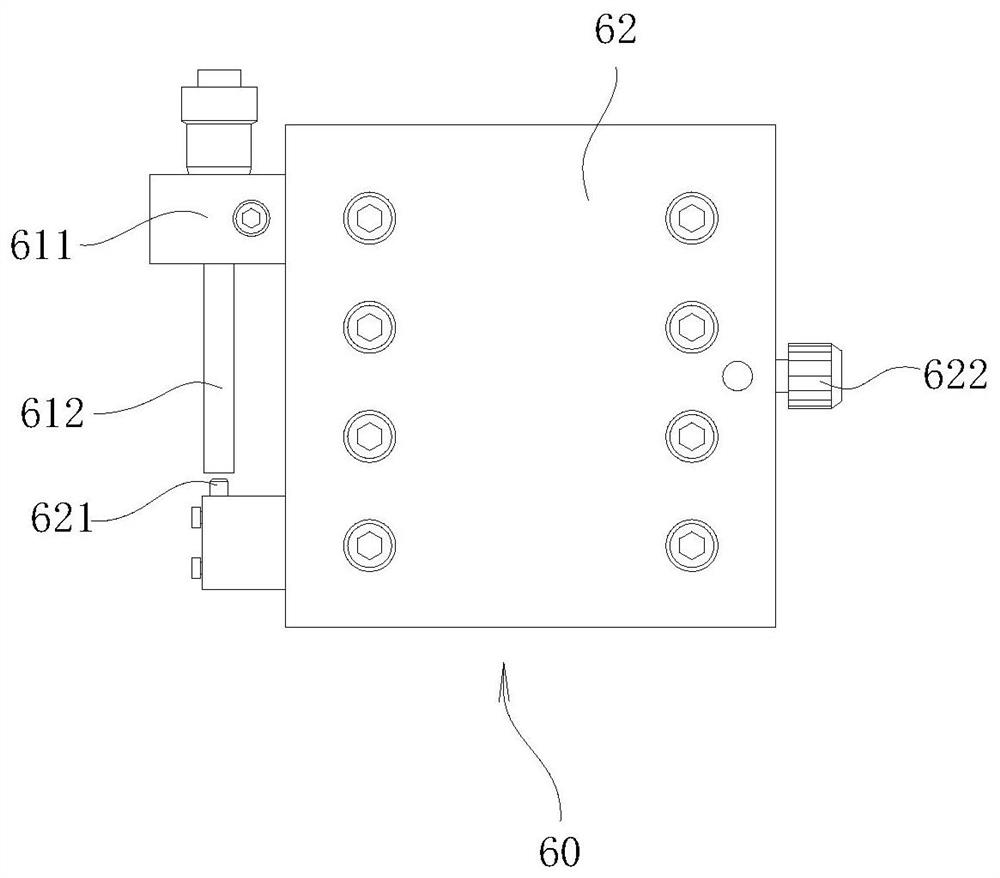

[0013] A miniature linear reciprocating friction and wear testing machine combined with in-situ observation of the friction interface, comprising a workbench 10, a slide table 20 is arranged on the workbench 10, a force sensor 30 is arranged on the slide table 20, and the force sensor 30 is fixed with a lower sample 40, the lower sample 40 is plate-shaped and the surface of the plate is horizontal, a crossbeam 50 is arranged above the workbench 10, and an upper slide table 60 is arranged on the crossbeam 50, and the upper slide An elastic plate 70 is suspended horizontally from the platform 60, the surface of the elastic plate 70 is horizontal, and an upper sample 80 is arranged on the end of the elastic plate 70, the upper sample 80 is cylindrical and the lower end is a hemisphere structure, the upper slide table 60 is provided with a first adjustment mechanism, the first adjustment mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com