Mechanical elastic wheel structural parameter optimization design method

A technology of elastic wheels and structural parameters, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as poor performance and low precision, and achieve the effect of simple design method, easy implementation and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

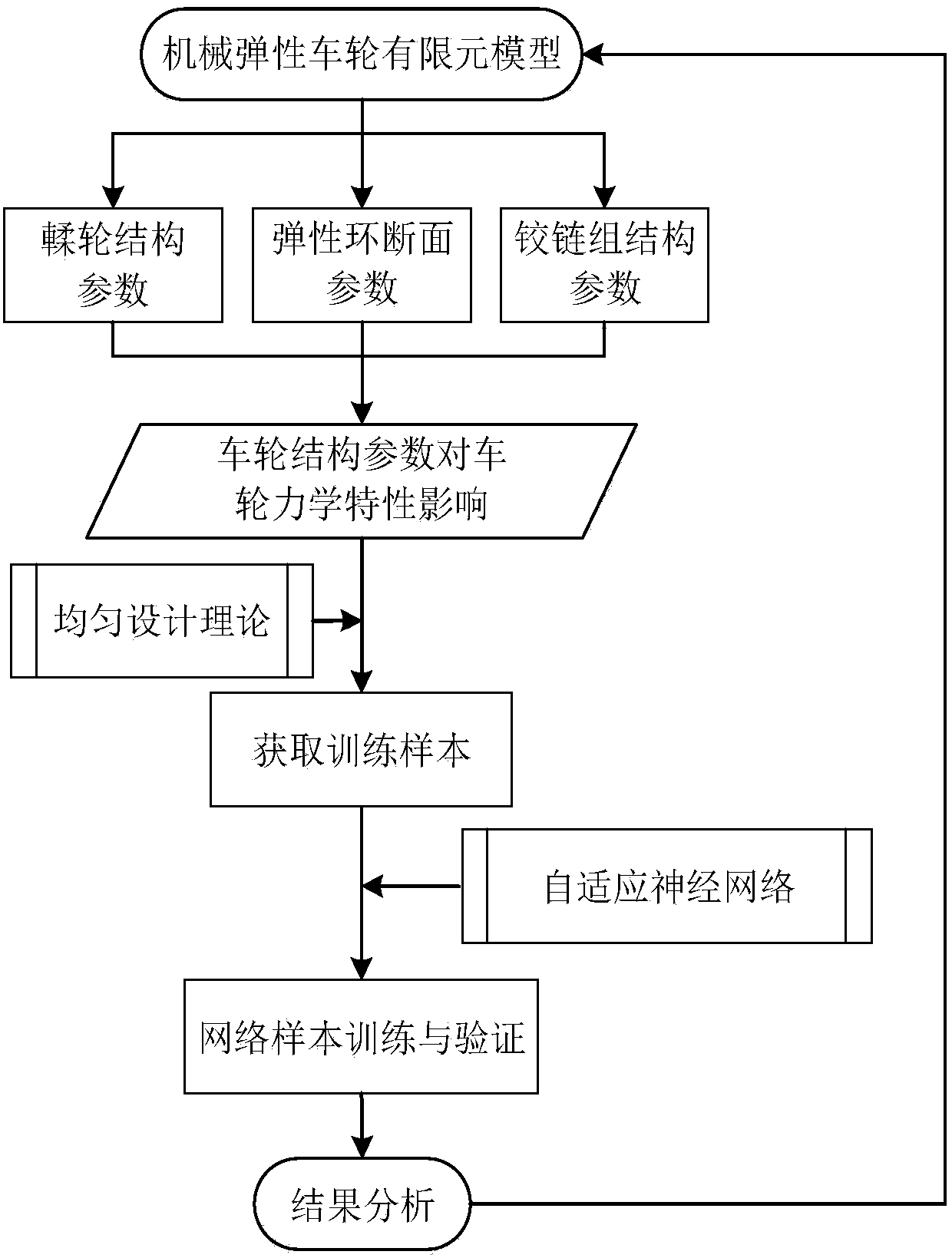

[0073] Such as figure 1 Shown, a kind of mechanical elastic wheel structure parameter optimal design method of the present invention comprises the following steps:

[0074] S1. Establish a mechanical elastic wheel finite element model; specifically include the following sub-steps:

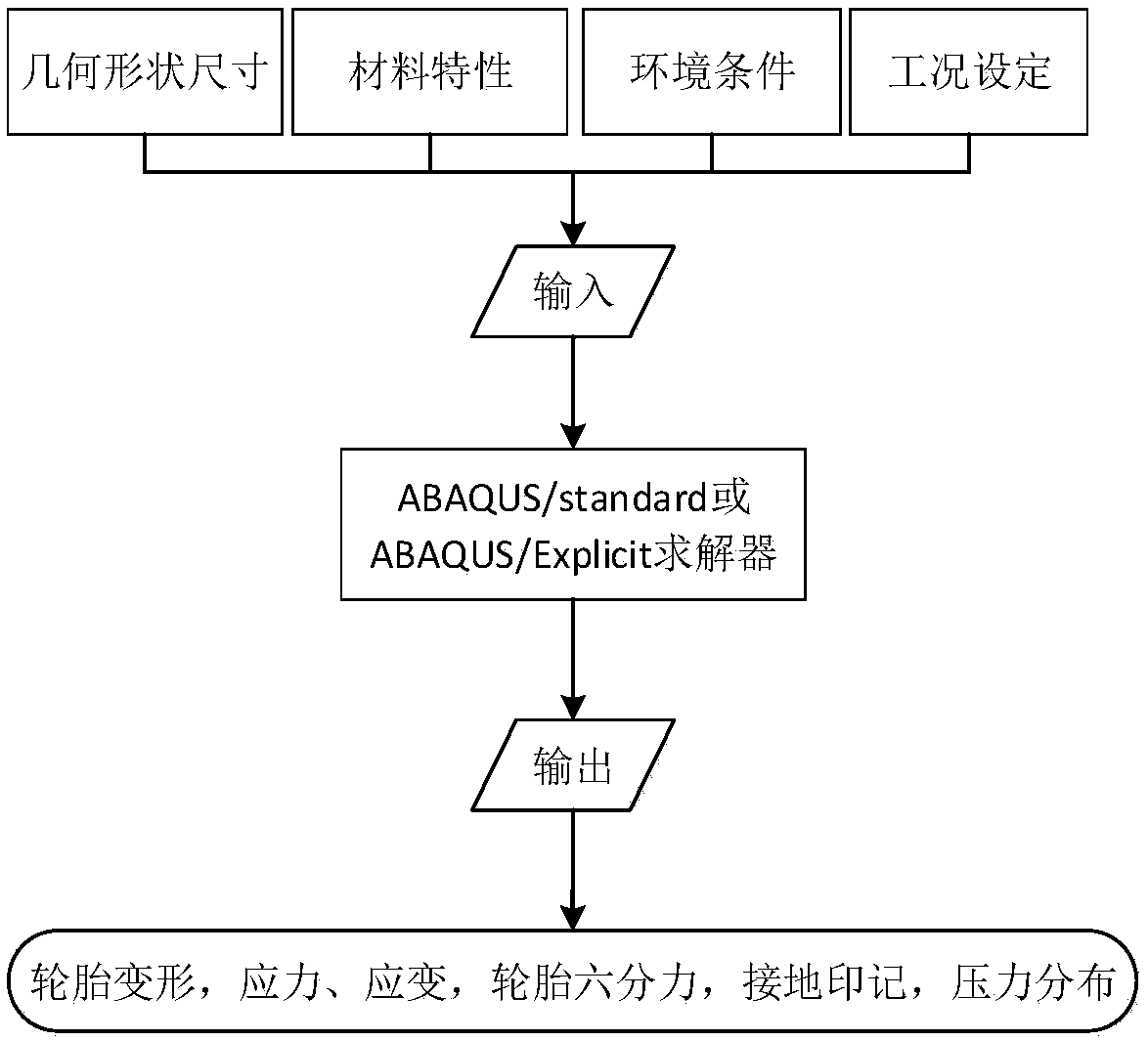

[0075] S11. The flow chart of the analysis of the mechanical characteristics of the finite element model is as follows: figure 2As shown, the mechanical elastic wheel structure is properly simplified under the premise of ensuring the reliability of the analysis results;

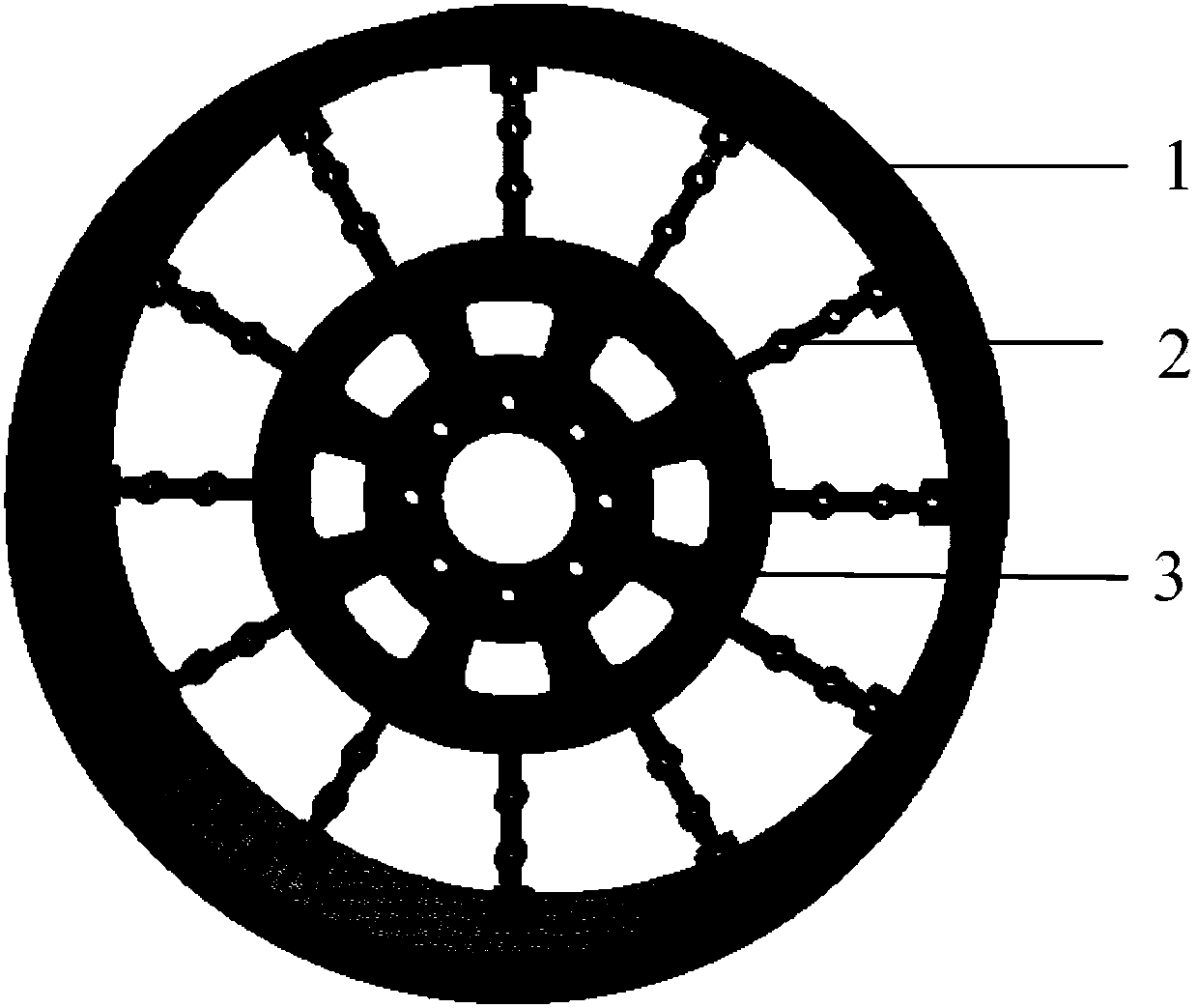

[0076] S12, as an embodiment, such as image 3 As shown, the main structure of the established mechanical elastic wheel finite element model includes a wheel, a hinge group, and a suspension hub;

[0077] S13. Perform test verification on the established mechanical elastic safety wheel simulation model.

[0078] S2. Establishing the collection simulation working conditions of the training samples; specifically including the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com