Fragrance for filter tip and preparation method and application thereof

A technology for filters and uses, which is applied in the field of filter aroma and its preparation, can solve problems such as poor taste, many harmful components, and poor effect of cigarette filter aroma enhancement, so as to achieve mellow smoke and compensate aroma loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the tobacco leaf extract described in the examples of this application comprises the following steps:

[0040] a) pulverize the tobacco leaves to below 300 mesh;

[0041] b) extracting with an aqueous ethanol solution to obtain an extract;

[0042] c) filtering the extract to obtain a filtrate;

[0043] d) adding glycerol as a stabilizer to the filtrate to obtain the final tobacco extract.

[0044] In the above-mentioned step a), the tobacco leaves are tobacco leaves produced in Zimbabwe. More preferably, the tobacco leaves include Zimbabwe tobacco L3L and Zimbabwe tobacco L3O.

[0045] The Zimbabwe tobacco extract L3L refers to the use of Zimbabwe tobacco, and the middle maturity grade is selected, that is, the third quality grade of the upper tobacco leaves in the standard grade, and it is lemon-colored.

[0046] The Zimbabwe tobacco extract L3O refers to the use of Zimbabwe tobacco, and the middle maturity grade is selected, that is, the...

Embodiment 1

[0052] Weigh 100 g of tobacco extract obtained from Zimbabwe tobacco L3L, 50 g of ethanol and 50 g of water and stir evenly. The temperature of the tower kettle was set at 195°C and heating was started. After about 15 minutes, the temperature at the top of the tower reached 72°C, and reflux began to appear. Keep the total reflux for 20min, the whole tower reaches a stable state, the temperature of the tower still does not change, it is about 89 ℃, and starts to discharge. When the temperature of the tower bottom reached 94°C, the discharge was stopped to obtain fraction 1. Continue to heat up the tower still to 200°C, keep the total reflux for 15 min, start discharging, and stop discharging when the temperature of the tower still reaches 98°C to obtain fraction 2. Then continue the above operation to obtain fraction 3.

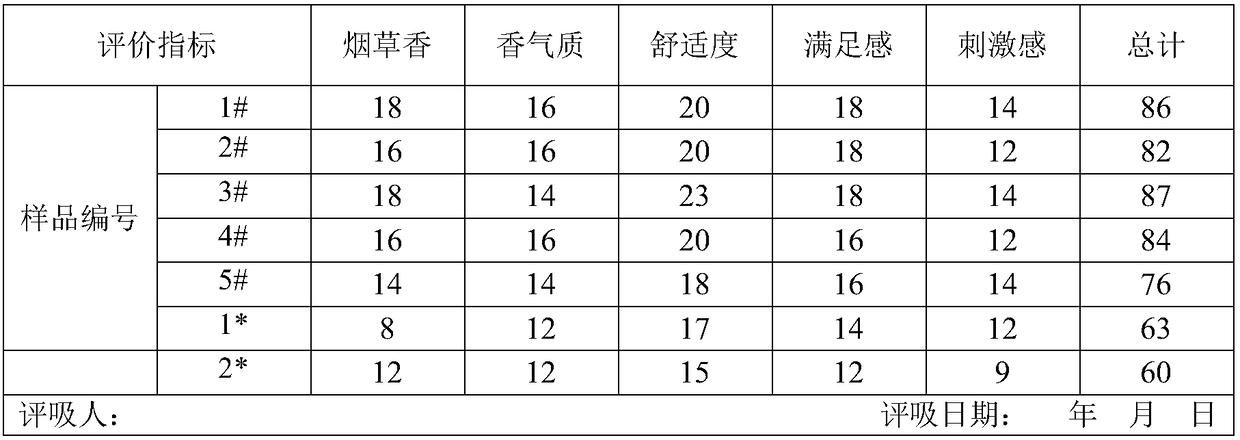

[0053] After small test evaluation, Fraction 1 has aroma effect, but the effect is not very significant. Fraction 2 has good aroma effect, and Fraction 3 ha...

Embodiment 2

[0055] The rectified fraction 2 in Example 1 was diluted with triacetin into a 1wt% solution, and the acetate fiber of the filter tip of a tobacco factory's coke-reduced smoke was added, and the mass ratio of the added amount to the acetate fiber was 10wt%. As the 2# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com