Upper side and lower side executing mechanism for intelligent dry separation machine

A technology of executive mechanism and dry separation machine, which is applied in the field of mineral dry separation to achieve the effects of less equipment, lower production costs, and low equipment use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

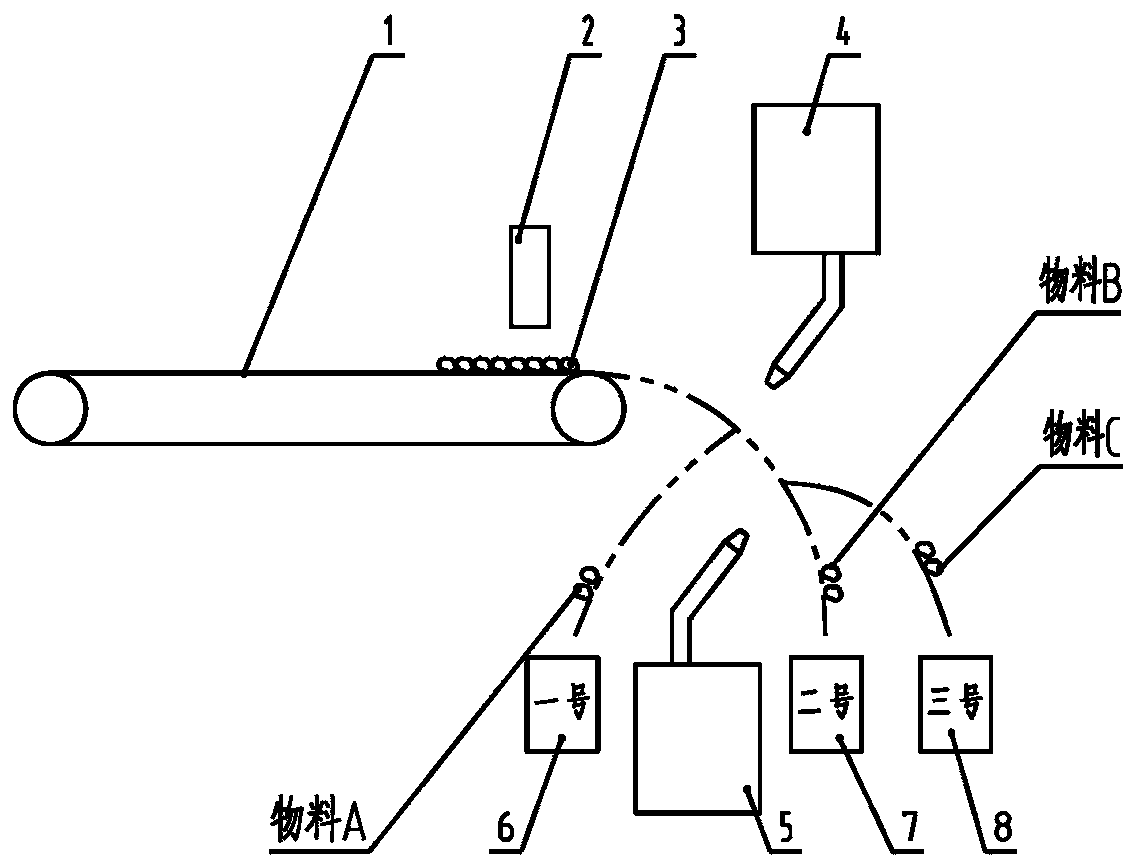

[0025] Such as figure 1 As shown, the upper and lower side actuators of the intelligent dry sorting machine in this embodiment include: an upper side actuator 4 and a lower side actuator 5.

[0026] In the intelligent dry sorting machine, the material 3 is transferred on the conveying device 1. Through the identification device 2 installed on the conveying device 1, the materials on the conveying device 1 can be identified as three types of products: material A, material B and material C, and The identification information and position information are respectively output to the corresponding upper side actuator 4 and lower side actuator 5, the upper side actuator 4 uses a high-frequency solenoid valve to control the air nozzle to blow and divide the identified material A from top to bottom. Optionally, the lower side actuator 5 uses a high-frequency sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com