A kind of bracket installation process method and its installation tool

A technology for installing tooling and brackets, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as low quality and inability to meet high precision, and achieve high precision, low manufacturing difficulty, and simple process methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The content of the present invention will be further described below in conjunction with the accompanying drawings.

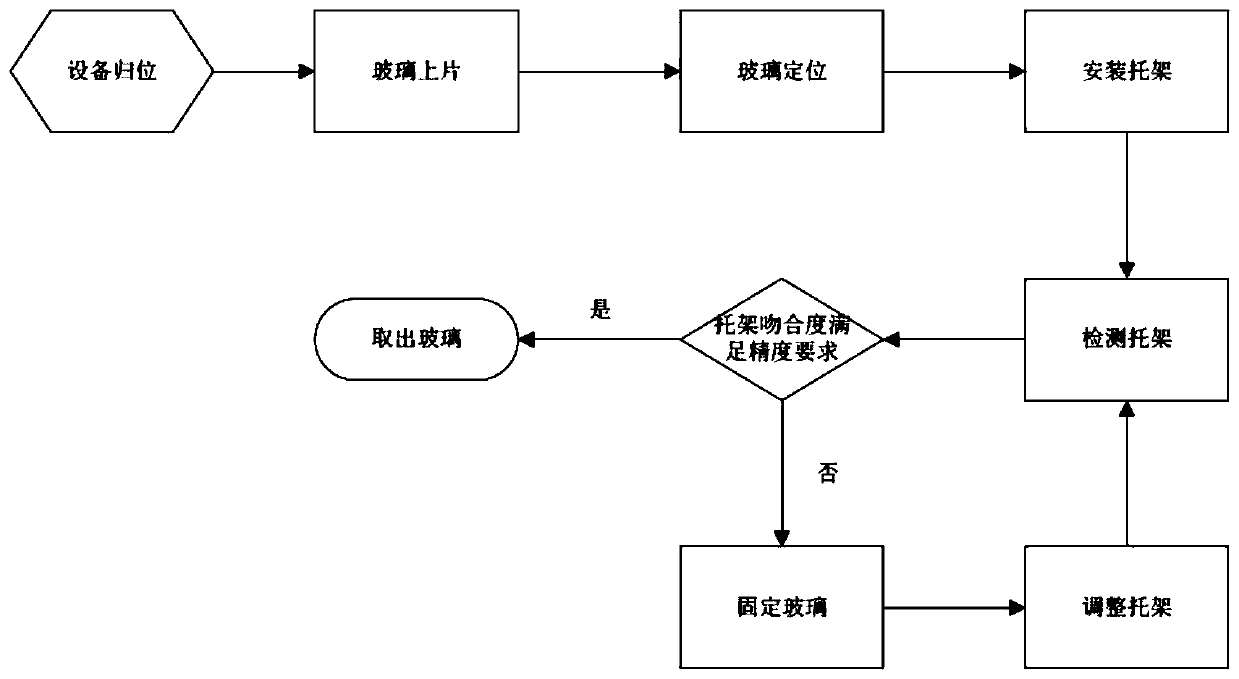

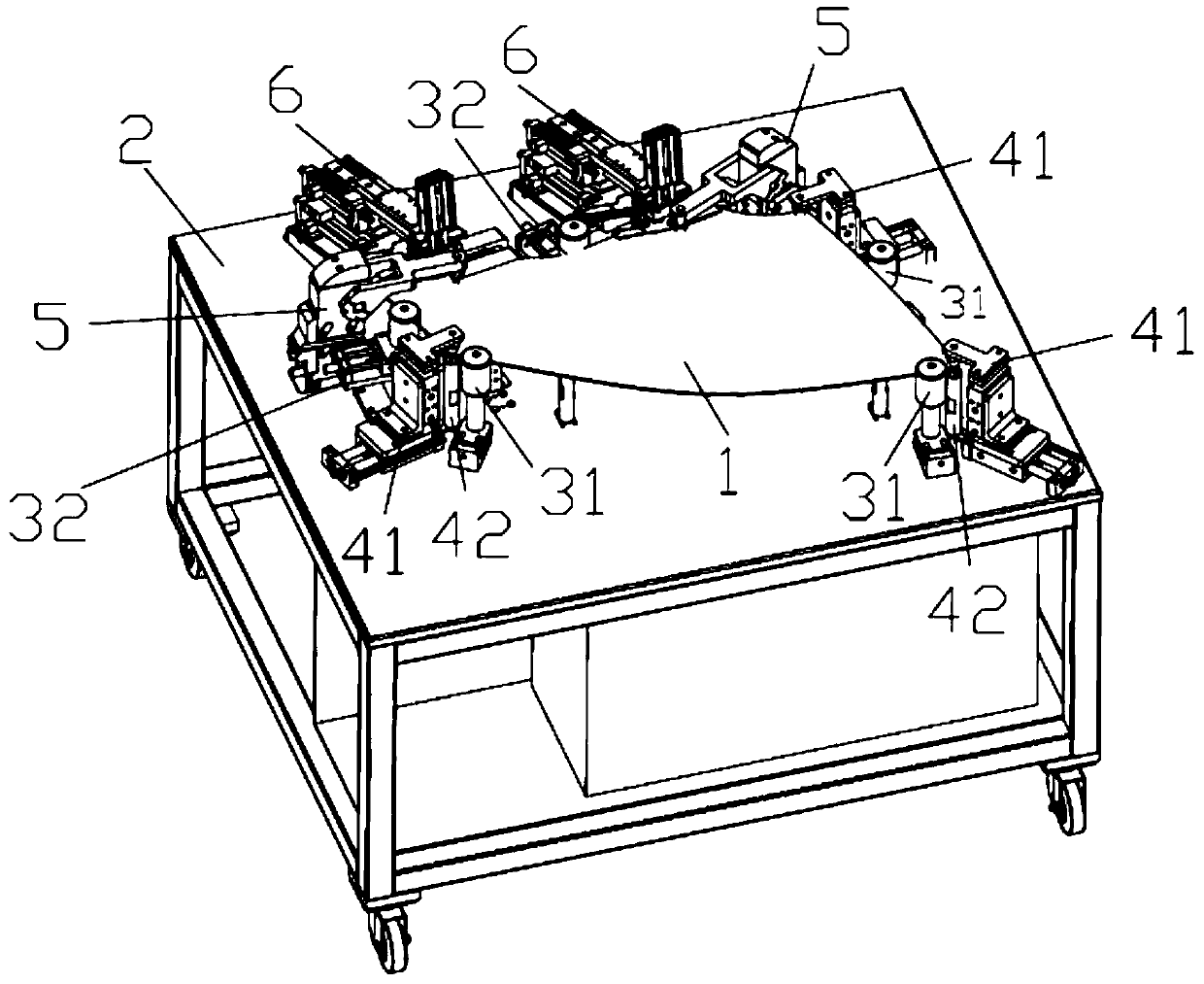

[0043] figure 1 A flow chart of the bracket installation process method of the present invention is shown, figure 2 Installation tooling for implementing this process method.

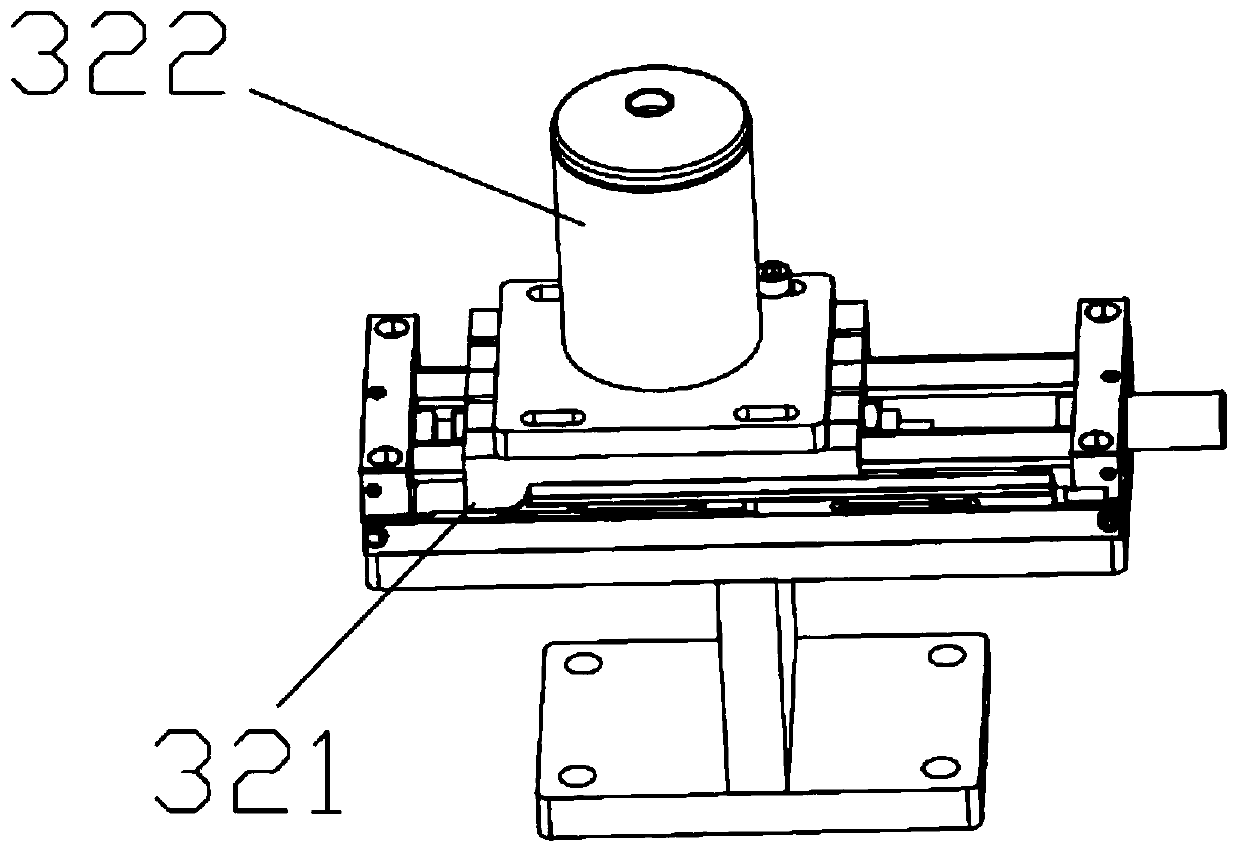

[0044] Before starting production, first reset the detection device on the bracket installation tool to zero. Start production, put the glass 1 on the supporting column 42, make the outline of the glass 1 touch the static positioning column 31, image 3 It is a structural schematic diagram of the clamping positioning column 32 , the horizontal sliding cylinder 321 drives the positioning column 322 to translate and compress the outline of the glass 1 , and the glass pressing mechanism 41 above the support column 42 acts to press and fix the glass 1 . Such as Figure 4 , Figure 5 As shown, the bracket is put into the bracket groove 65, the positioning pin 651 on the bracket g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com