Continuous tank-type wood carbonizing device

A carbonization device and wood technology, applied in the field of wood processing, can solve problems such as poor carbonization effect and carbonization efficiency, and achieve the effects of improving carbonization efficiency, improving heat transfer efficiency, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

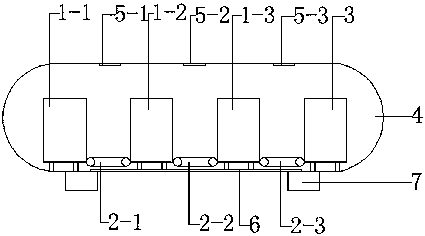

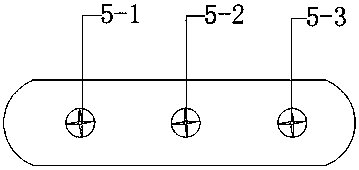

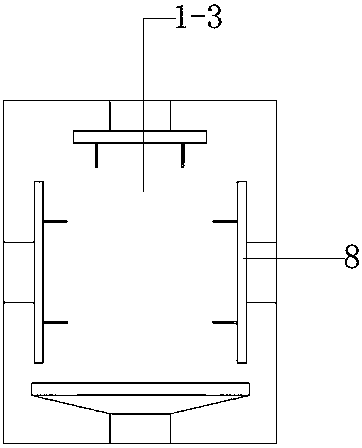

[0020] A continuous tank type wood carbonization device, mainly comprising: a heating device 1, a conveying device 2, a cooling device 3 and a tank body 4, the tank body 4 has a ventilation device 5, the tank body 4 contains a water tank 6, and the heating device 1 contains three Heating boxes, respectively No. 1 heating box 1-1, No. 2 heating box 1-2 and No. 3 heating box 1-3; the front of the device is No. 1 heating box 1-1, and the rear of No. 1 heating box 1-1 No. 1 transfer device 2-1, No. 1 transfer device 2-1 is connected to No. 2 heating box 1-2, No. 2 heating box 1-2 is connected to No. 2 transfer device 2-2, No. 2 transfer device 2 No. 3 heating box 1-3 is connected after -2, No. 3 heating box 1-3 is connected with No. 3 transfer device 2-3, and No. 3 transfer device 2-3 is connected with cooling device 3 after No. 3 transfer device 2-3, between heating device 1 and The lower end of the transmission device 2 has a water tank 6, and the upper end has a ventilation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com