Transfer trolley for parts of small automobile

A small car and parts technology, applied in the field of auto parts, can solve the problems of large storage space, low labor efficiency, inconvenient transfer, etc., and achieve the effect of reducing storage space, convenient handling and transfer, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

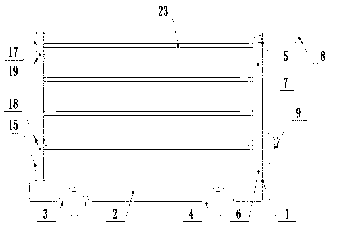

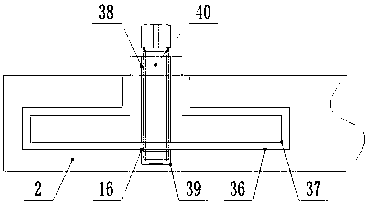

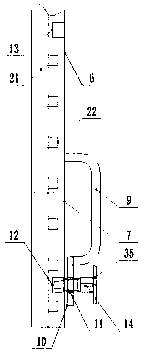

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5Shown, a kind of trolley that is used for small auto parts transfer, comprises cart frame 1, and described cart frame 1 is respectively provided with driving wheel 3, base frame 1 by base rectangular base 2, the two sides below the front end of base rectangle base 2 respectively. The universal wheels 4 provided on both sides below the rear end of the rectangular base 2 and the push handle 5 provided at the rear end of the basic rectangular base 2 are composed of the upper end of the rear side of the basic rectangular base 2 and along its left and right width. The push-down hand frame 6 provided with fixed direction, the push-up hand frame 7 provided above the push-down hand frame 6, the push rods 8 hinged respectively on both sides of the top of the push-up hand frame 7, the push-up hand frame 7 and the rear end surface of the push-down hand frame 6 One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com