Full-automatic paper unloading stacker

A paper palletizer, fully automatic technology, applied in the direction of stack receiving device, thin material handling, transportation and packaging, etc., can solve the problems of poor stacking uniformity of unloaded paper, error of unloaded paper amount, failure of unloaded paper work, etc. , to achieve the effect of accurate paper unloading, high accuracy and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

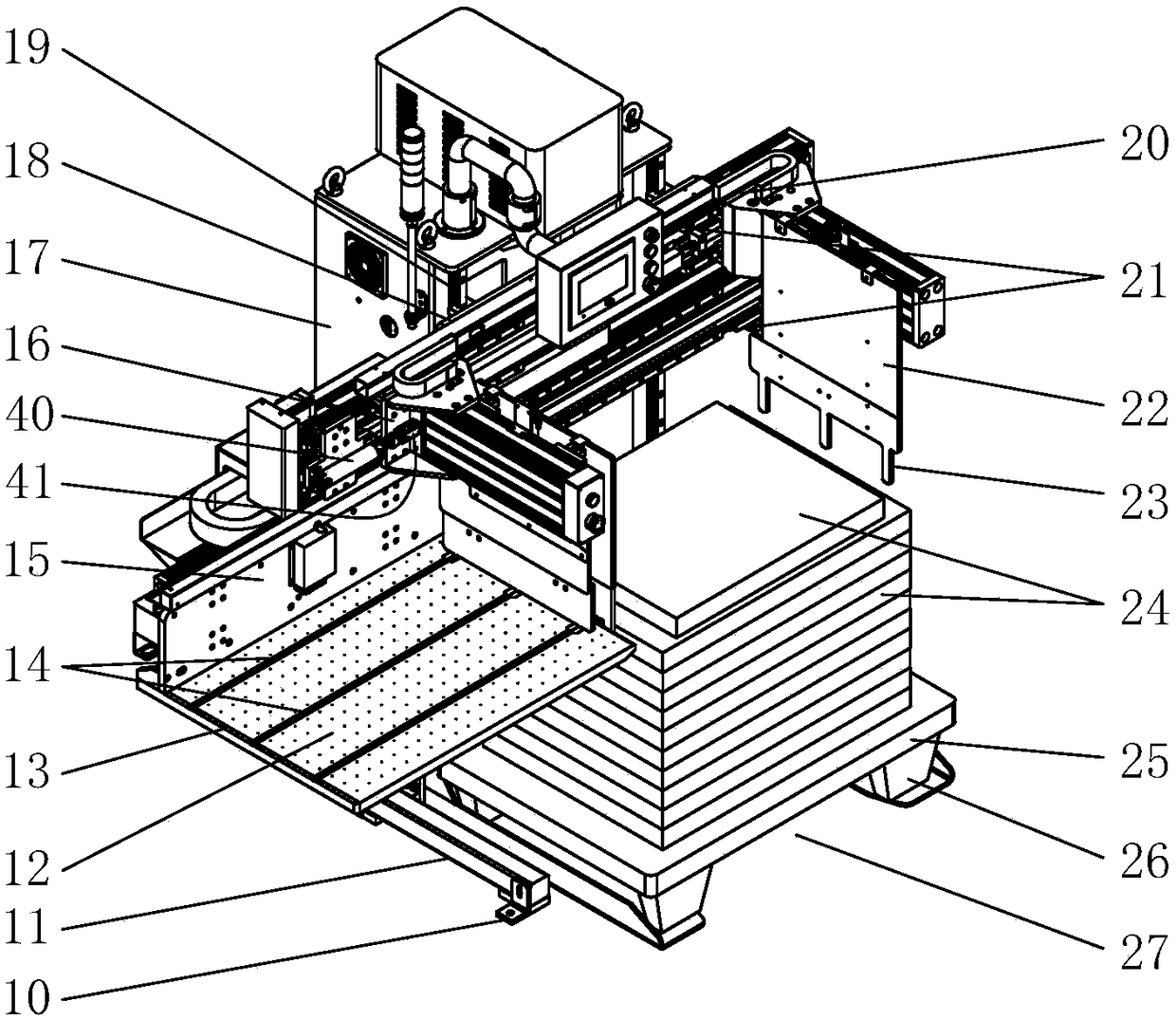

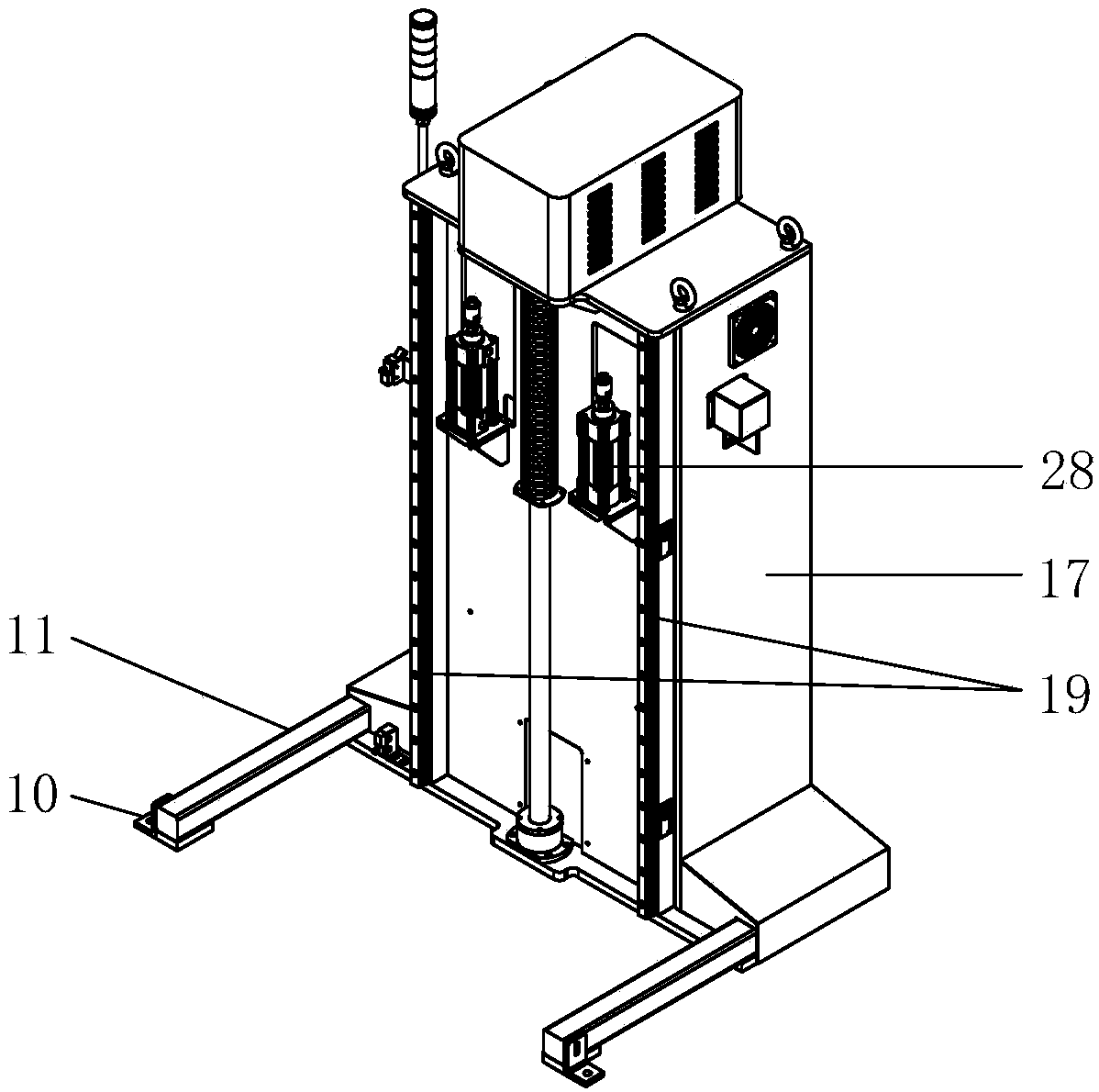

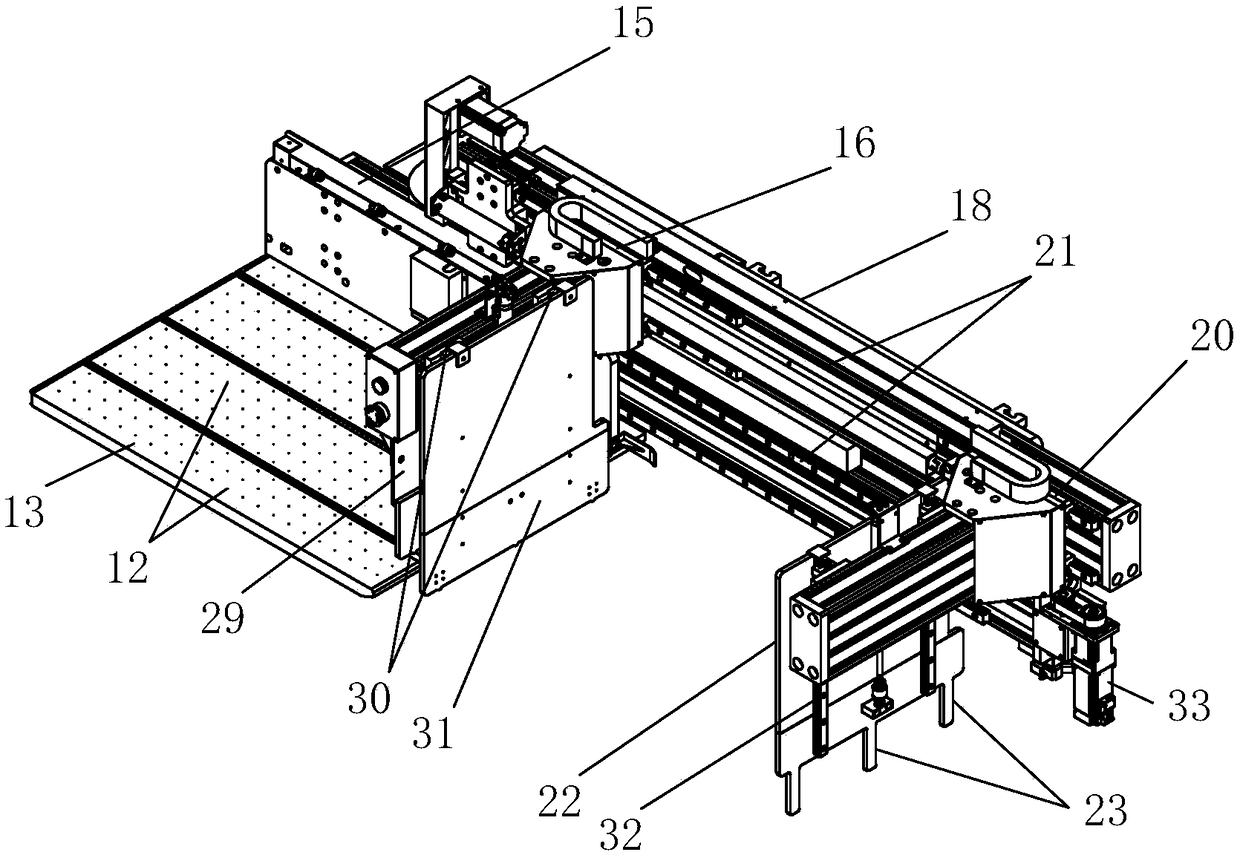

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 4 :

[0025] A kind of full-automatic paper unloading stacker, comprises machine base 17, and the side surface of described machine base 17 is provided with vertical first slide rail 19, and first slide rail 19 is provided with power-driven on the first slide rail. The first slide plate 18 that slides vertically on the rail 19, the second slide plate 15 and the third slide plate that are driven by power to slide horizontally on the second slide rail 21 respectively on the horizontal second slide rail 21 of the first slide plate 18 16 and the fourth slide plate 20, the underside of the second slide plate 15 is equipped with an air cushion platform 13 protruding forward, and the third slide plate 16 is provided with a paper stacking baffle plate 29 driven by power to slide laterally on the second slide rail 21 , the vertical third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com