Match processing device

A processing device and match technology, applied in the direction of matches, etc., can solve the problems that affect the processing effect and efficiency, cannot be completed synchronously, and it is difficult to complete the planing process, etc., and achieve the effect of good manufacturing effect, convenient operation and improved practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

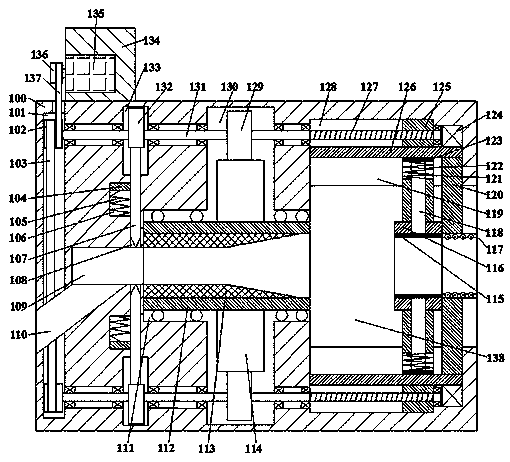

[0016] Such as figure 1 As shown, a match processing device of the present invention includes a fuselage 100 and a cylindrical processing cavity 111 arranged in the fuselage 100, and the inner wall of the right end of the cylindrical processing cavity 111 is communicated with a continuous material opening to the right. Cavity 138, the upper and lower inner walls of the refill chamber 138 are connected with a first symmetrical guide chute 119, and the inner wall of the first guide chute 119 away from the refill chamber 138 is connected with a second guide slide Groove 128, the fuselage 100 is provided with a first cavity 130 passing through the processing cavity 111, the inner wall of the left end of the processing cavity 111 is connected with a cutting cavity 109, and the inner wall of the bottom of the cutting cavity 109 is connected with a The ejection port 110 is inclined downward. The body 100 is provided with a second cavity 133 located at the upper and lower ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com