Nontoxic copper-iron based silver stripping solution and stripping technology thereof

A deplating solution and copper-iron technology, which is applied in the field of non-toxic copper-iron-based silver deplating solution and its deplating process, can solve the problems of short deplating completion cycle and achieve short deplating completion cycle and workpiece quality assurance High, comprehensive deplating performance and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

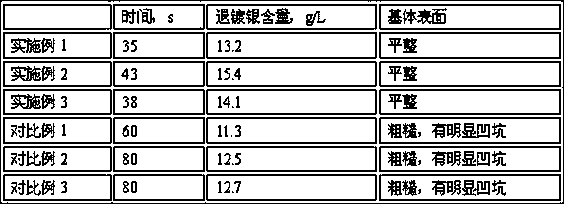

Examples

Embodiment 1

[0022] A non-toxic copper-iron-based silver stripping solution, comprising the following components in mass percentage: 10% oxidizing agent, 25% complexing agent, 8% composite surfactant, water balance, wherein the oxidizing agent is a combination of hydrogen peroxide and ammonia water The complexing agent includes glycine, citrate, triethanolamine, and the composite surfactant includes alkyl sugar amine type surfactant and anionic surfactant, and also includes buffering agent 6%, and the buffering agent includes acetate and thiourea.

[0023] Wherein: water adopts deionized water, hydrogen peroxide adopts mass fraction 35%, ammoniacal liquor adopts mass fraction 25%, citrate adopts sodium citrate; Acetate adopts sodium acetate, and the mass ratio of acetate and thiourea is 2: 2. The amount of ammonia added in the oxidant is 10% of the mass of hydrogen peroxide; the molar ratio of glycine, citrate, and triethanolamine in the complexing agent is 1:2:1, and the complexing agent ...

Embodiment 2

[0029] A non-toxic copper-iron-based silver stripping solution, comprising the following components in mass percentage: 15% oxidizing agent, 40% complexing agent, 5% composite surfactant, and water balance, wherein the oxidizing agent is a combination of hydrogen peroxide and ammonia water The complexing agent includes glycine, citrate, triethanolamine, and the composite surfactant includes alkyl sugar amine type surfactant and anionic surfactant, and also includes buffering agent 4%, and the buffering agent includes acetate and thiourea.

[0030] Wherein: water adopts deionized water, hydrogen peroxide adopts mass fraction 35%, ammoniacal liquor adopts mass fraction 25%, citrate adopts sodium citrate; Acetate adopts sodium acetate, and the mass ratio of acetate and thiourea is 4: 2. The amount of ammonia added in the oxidant is 10% of the mass of hydrogen peroxide; the molar ratio of glycine, citrate, and triethanolamine in the complexing agent is 1:2:1, and the complexing ag...

Embodiment 3

[0033] A non-toxic copper-iron-based silver stripping solution, comprising the following components in mass percentage: oxidant 12%, complexing agent 45%, composite surfactant 5%, water balance, wherein the oxidant is a combination of hydrogen peroxide and ammonia The complexing agent includes glycine, citrate, triethanolamine, and the composite surfactant includes an alkyl sugar amine type surfactant and anionic surfactant, and also includes buffering agent 10%, and the buffering agent includes acetate and thiourea.

[0034]Wherein: water adopts deionized water, hydrogen peroxide adopts mass fraction 35%, ammoniacal liquor adopts mass fraction 25%, citrate adopts potassium citrate; Acetate adopts potassium acetate, and the mass ratio of acetate and thiourea is 3: 2. The amount of ammonia added in the oxidant is 20% of the mass of hydrogen peroxide; the molar ratio of glycine, citrate, and triethanolamine in the complexing agent is 1:2:2, and the complexing agent also contains...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap