Multifunctional artillery cleaning machine

A gun cleaning machine and multi-functional technology, which is applied in the direction of weapon accessories, offensive equipment, weapon cleaning devices, etc., can solve the problems of unreliable artillery, inconsistent standards, and high labor intensity, and achieve significant economic benefits and popularization and application Foreground, difficulty of research, effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

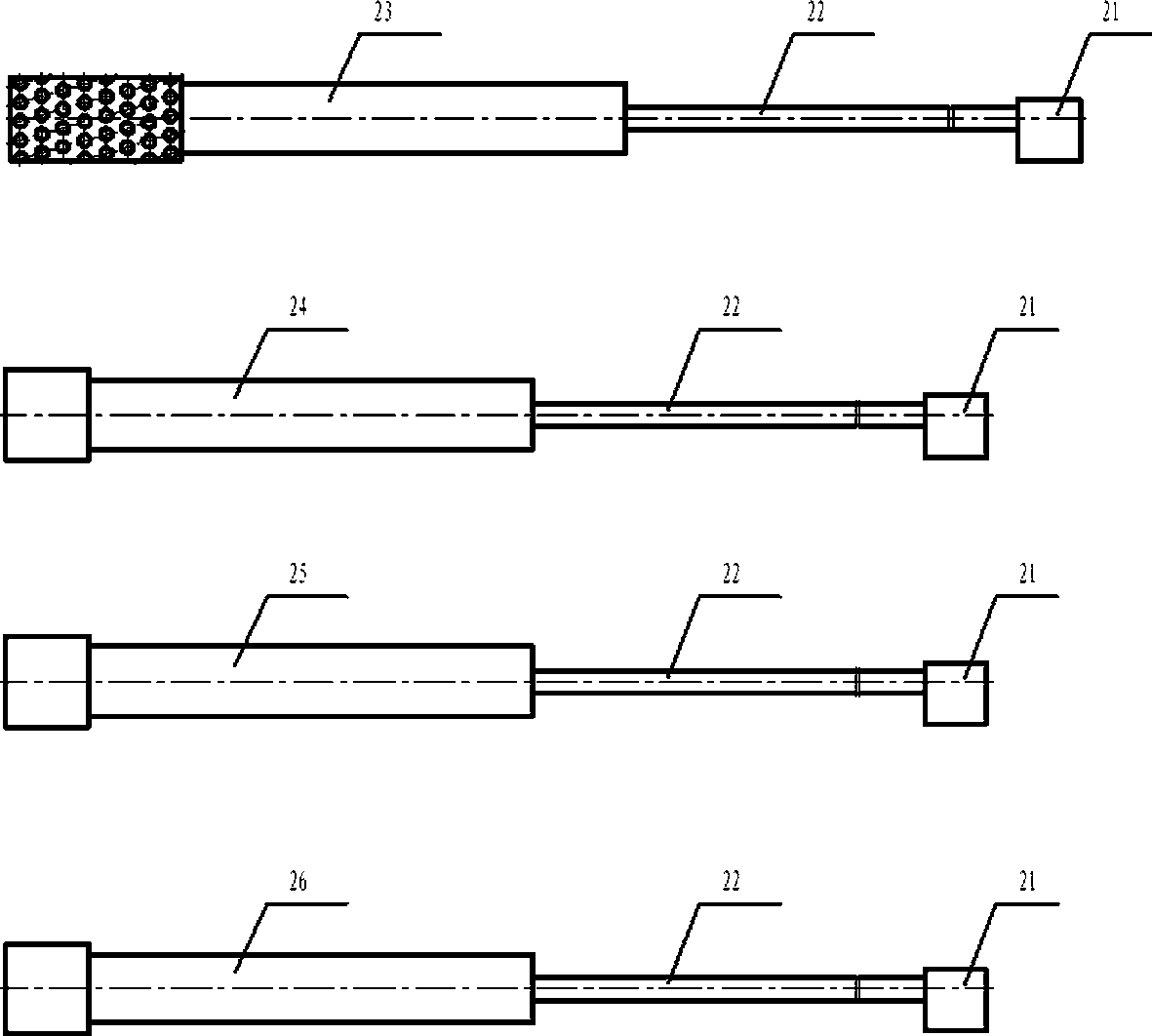

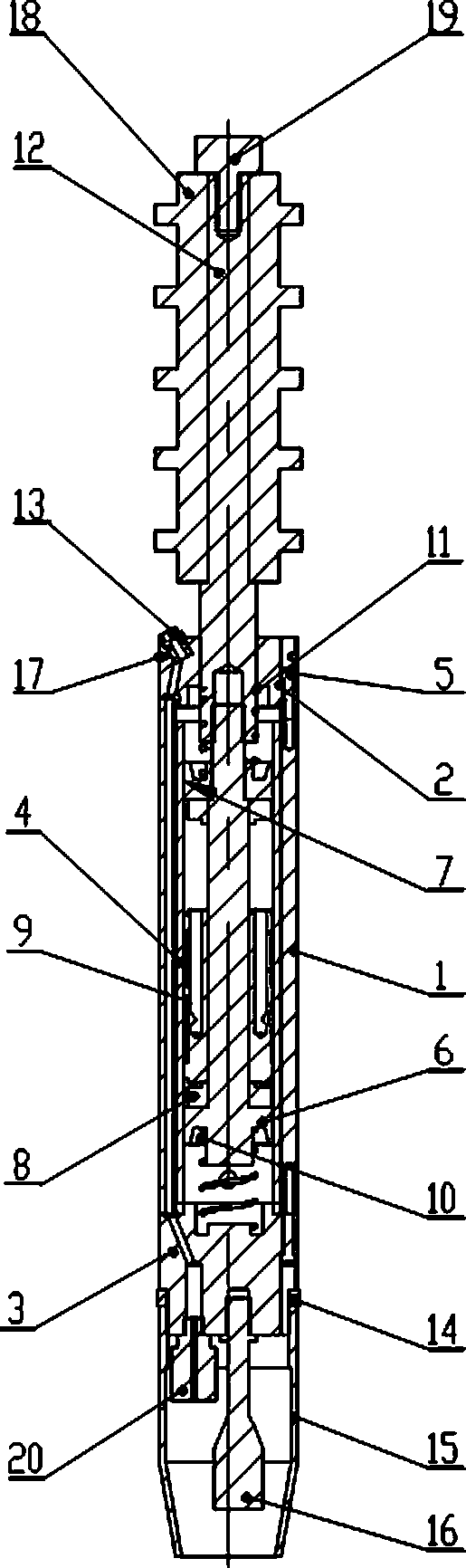

[0030] Below in conjunction with accompanying drawing, the present invention will be further described. like Figure 1-Figure 2 As shown, a kind of multi-functional cannon wiping machine comprises a pneumatic control box 21, an air intake pipe 22 and a wiping host 23 which are sequentially connected to form a whole. The wiping host includes a host body 1 and a wiping brush 18. A cylinder liner 4, a slide block 9 and a central shaft 6 are provided for sliding fit, and a screw shaft 12 is arranged in the center of a wiping brush 18, and one end of the central shaft 6 is connected to the screw shaft 12, and then the screw shaft 12 is embedded in the front of the main body 1 The other end of the central shaft 6 is inserted into the guide fixing seat 2 and then the guiding fixing seat 3 is connected with the intake screw 16 .

[0031] The tail of the host body 1 is connected with a positioning ring 14 and a protective back cover 15 .

[0032] The central axis 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com