Fiber grating sensor package structure and packaging method suitable for high-temperature environment

A fiber grating and packaging structure technology, applied in the field of sensors, can solve the problems of fiber grating sensor performance influence, inaccurate measurement results, poor bonding effect, etc., and achieve the effects of simple packaging, simple operation, and convenient bonding and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

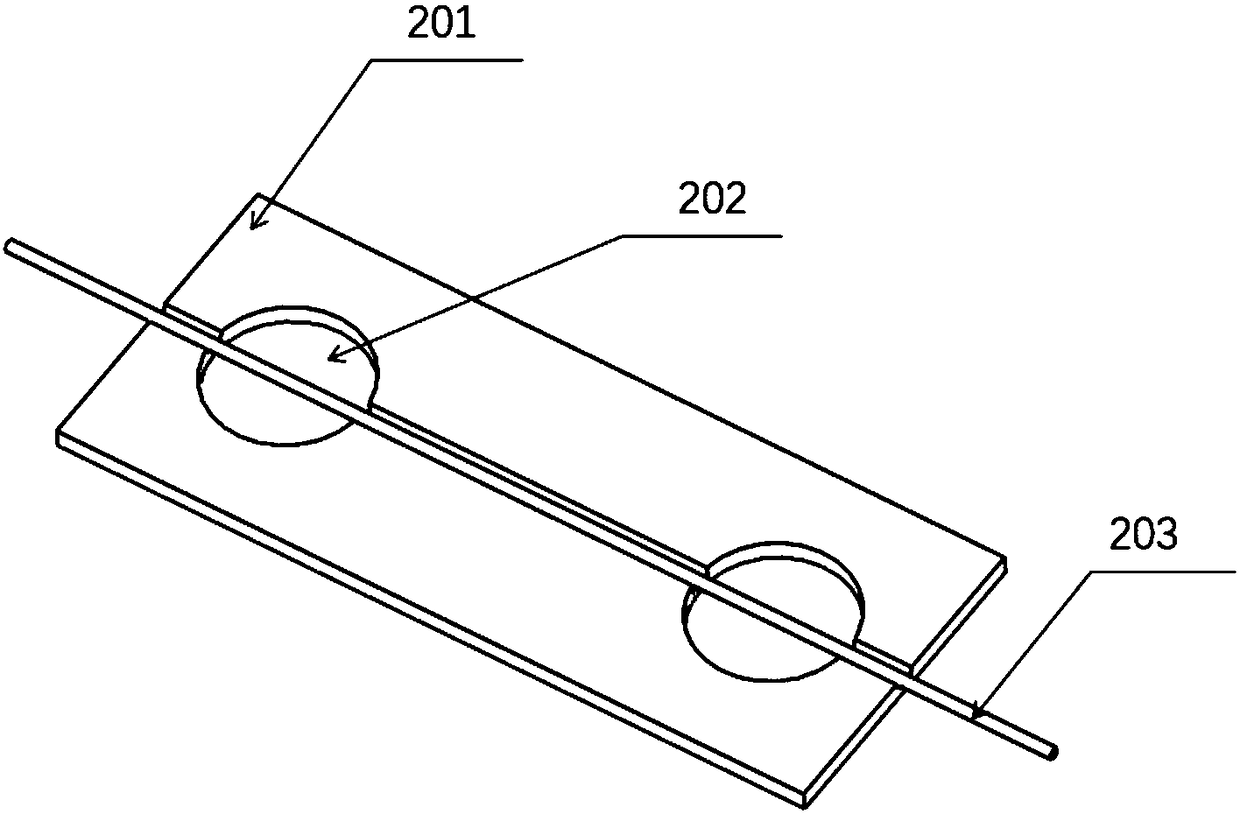

[0046] Such as Figure 1 to Figure 4 As shown, a fiber grating sensor packaging structure suitable for high-temperature environments provided by the embodiment of the present invention includes an upper package 101 and a lower package 201, and the lower package 201 is provided with two optical fiber fixing through holes 202 arranged at intervals for utilizing The high temperature adhesive fixes the fiber grating sensor 203 on the object under test. Preferably, the high-temperature adhesive can be selected from Resbond 989FS, 940HT Powder or other similar products.

[0047]The lower package 201 is also provided with an optical fiber placement part, which passes through two optical fiber fixing through holes and is divided into a first placement part, a second placement part and a third placement part by the two fiber fixing through holes 202. The placement part is located between the two optical fiber fixing through holes, and is used to place the sensing area of the fiber g...

Embodiment 2

[0061] Such as Figure 5 As shown, the second embodiment is basically the same as the first embodiment, except that the second placement part and the third placement part are both grooves, and the first placement part is a long hole structure, that is, two optical fiber fixing through holes 202 To ensure that the sensing area of the fiber grating sensor 203 is neither in contact with the upper package 101 nor with the lower package 201 . Due to the high viscosity of the high-temperature adhesive, the high-temperature adhesive will not flow into the sensing area of the FBG sensor 203 even if it is connected between the two optical fiber fixing through holes 202 , and the performance of the FBG sensor 203 will not be affected.

Embodiment 3

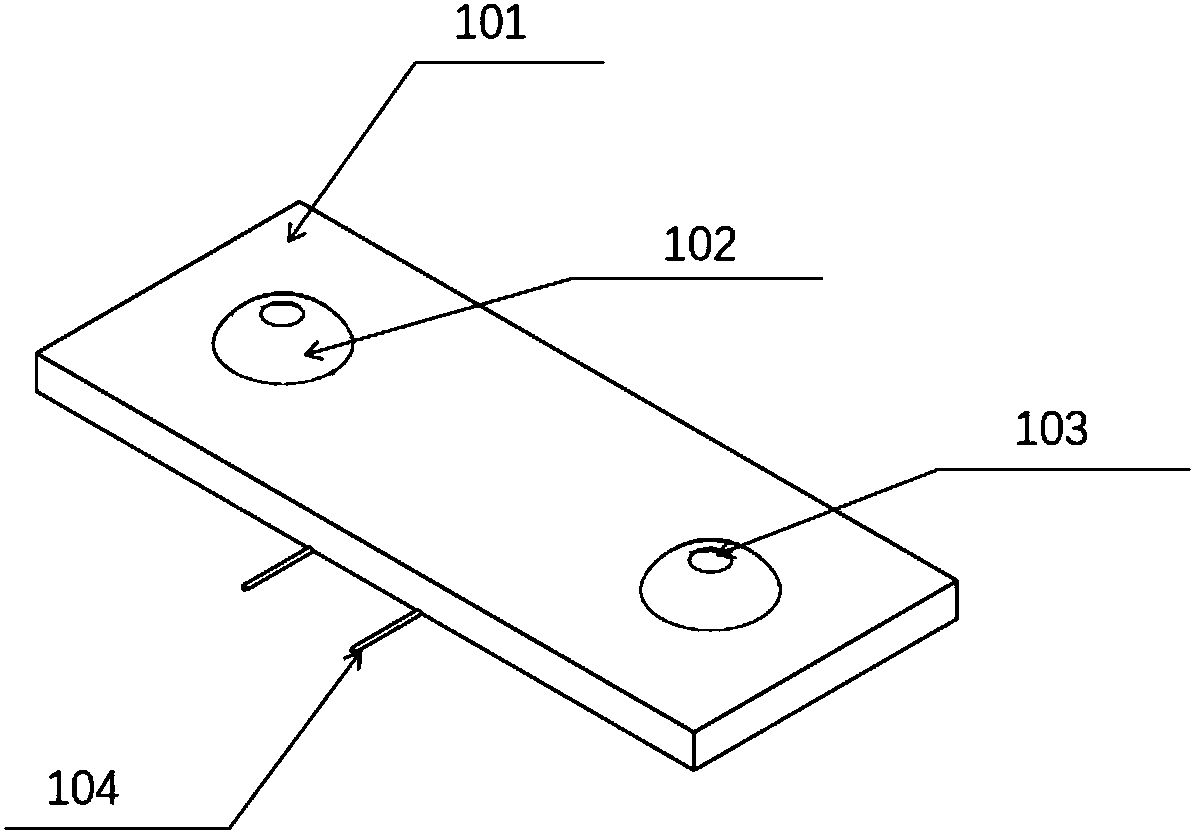

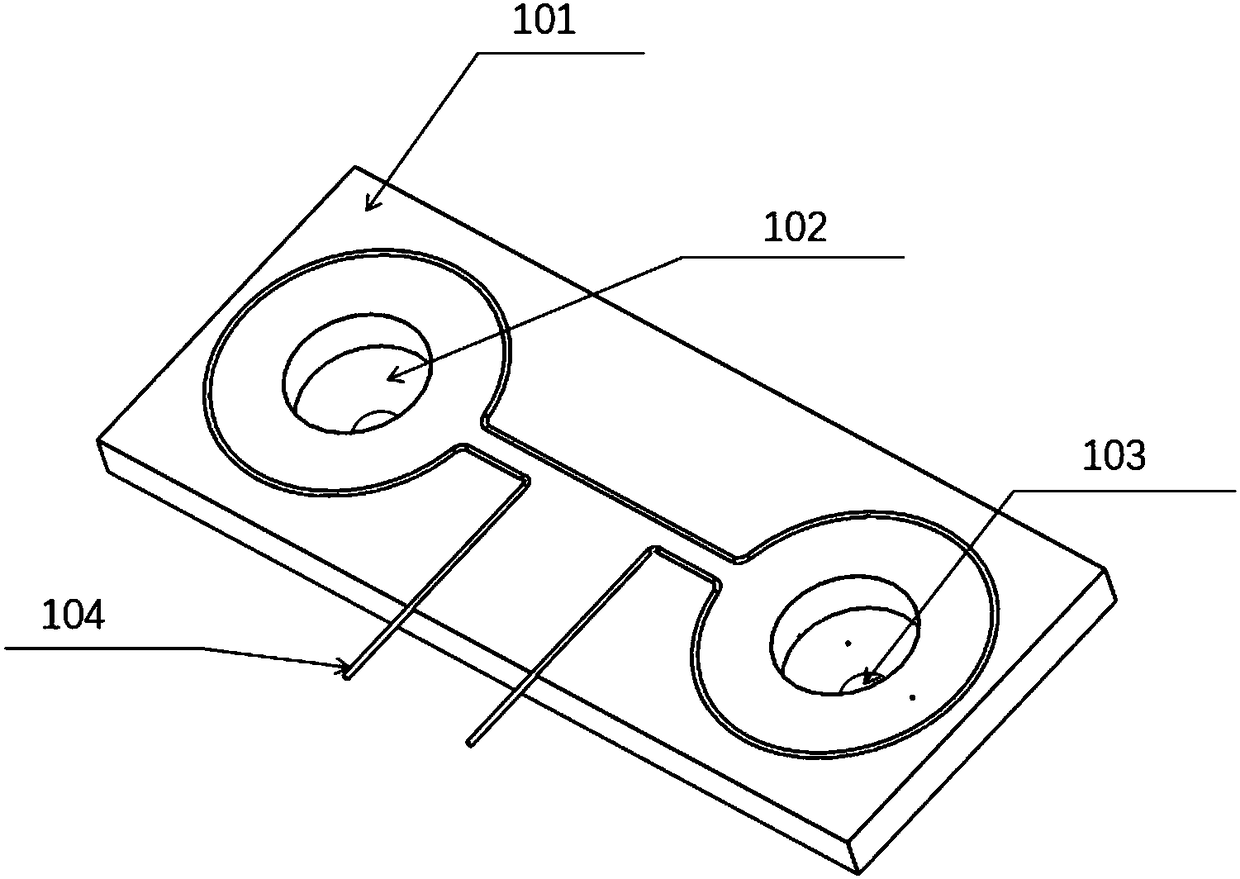

[0063] Such as Figures 6 to 11 As shown, this embodiment also provides a fiber grating sensor packaging structure suitable for high-temperature environments. The third embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The differences are:

[0064] Specifically in this embodiment, the lower package 201 is a flat rectangular parallelepiped, and the two optical fiber fixing through-holes 202 arranged at intervals on the lower package 201 are tapered holes with a small opening at the top and a large opening at the bottom. Preferably, the cavity inside the optical fiber fixing through hole 202 is in the shape of an inverted bowl.

[0065] The structure of the upper package 101 is thinner than that of the lower package 201. The interior of the two injection holes 103 on the upper package 101 is funnel-shaped, that is, a tapered hole with a large opening at the top and a small opening at the bottom. Bottom protruding downwards (eg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com