Magnetic thin film inductor structures

A magnetic thin film and inductor technology, applied in the direction of inductors, transformer/inductor cores, electric solid devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

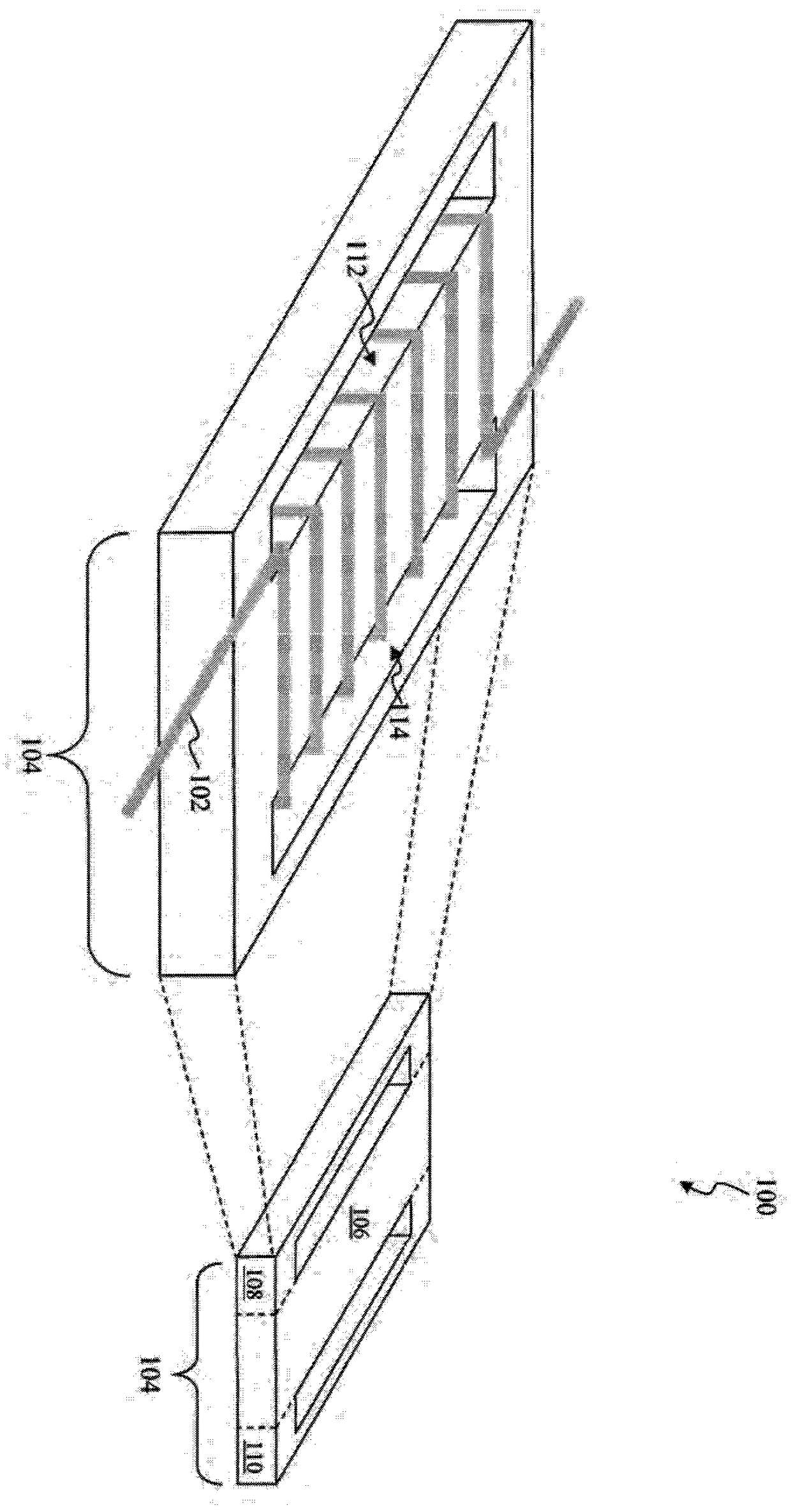

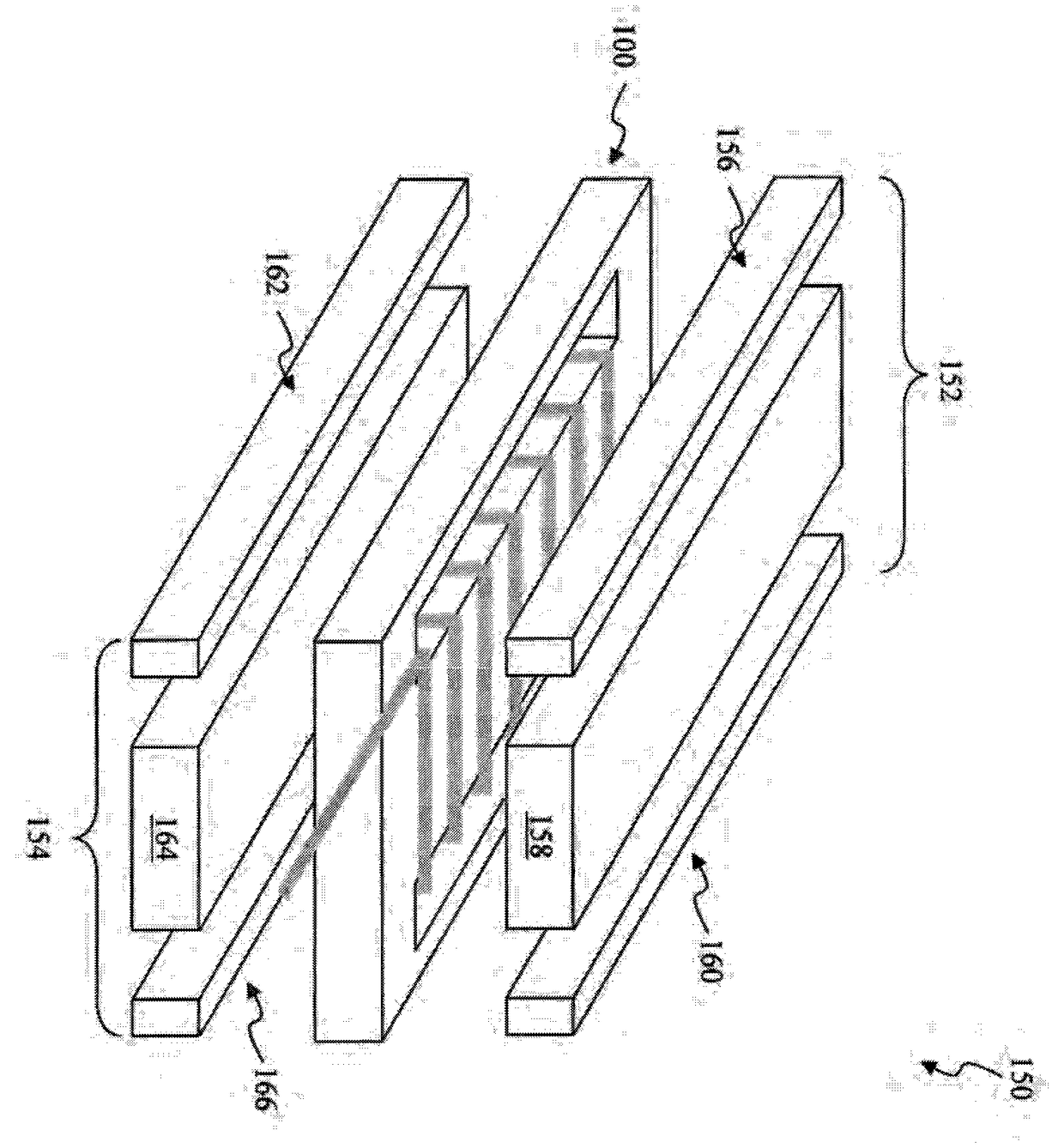

[0032] Although in Figure 1C The first magnetic thin film planar structure 152 and the second magnetic thin film planar structure 154 are described as rectangular parallelepipeds, but those skilled in the art will recognize that the Other embodiments: such as one or more three-dimensional regular closed geometric structures, such as for example one or more three-dimensional regular polygons; one or more three-dimensional irregular closed structures, such as for example one or more three-dimensional irregular polygons; and / or any suitable combination of these closed structures. In an exemplary embodiment, the first magnetic thin film planar structure 152 and / or the second magnetic thin film planar structure 154 can be utilized as described above in Figure 1A The magnetic thin film material and / or the parallel magnetic thin film material described in are implemented. In some cases, the magnetic thin film material can be as above in Figure 1A Depositing on one or more ferroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com