LCC-MMC system input control method of single valve group and direct current transmission system

A control method, DC current technology, applied in the direction of power transmission AC network, etc., can solve the problem of single valve group online input, etc., to achieve the effect of high reactive power demand, flexible control, and large harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

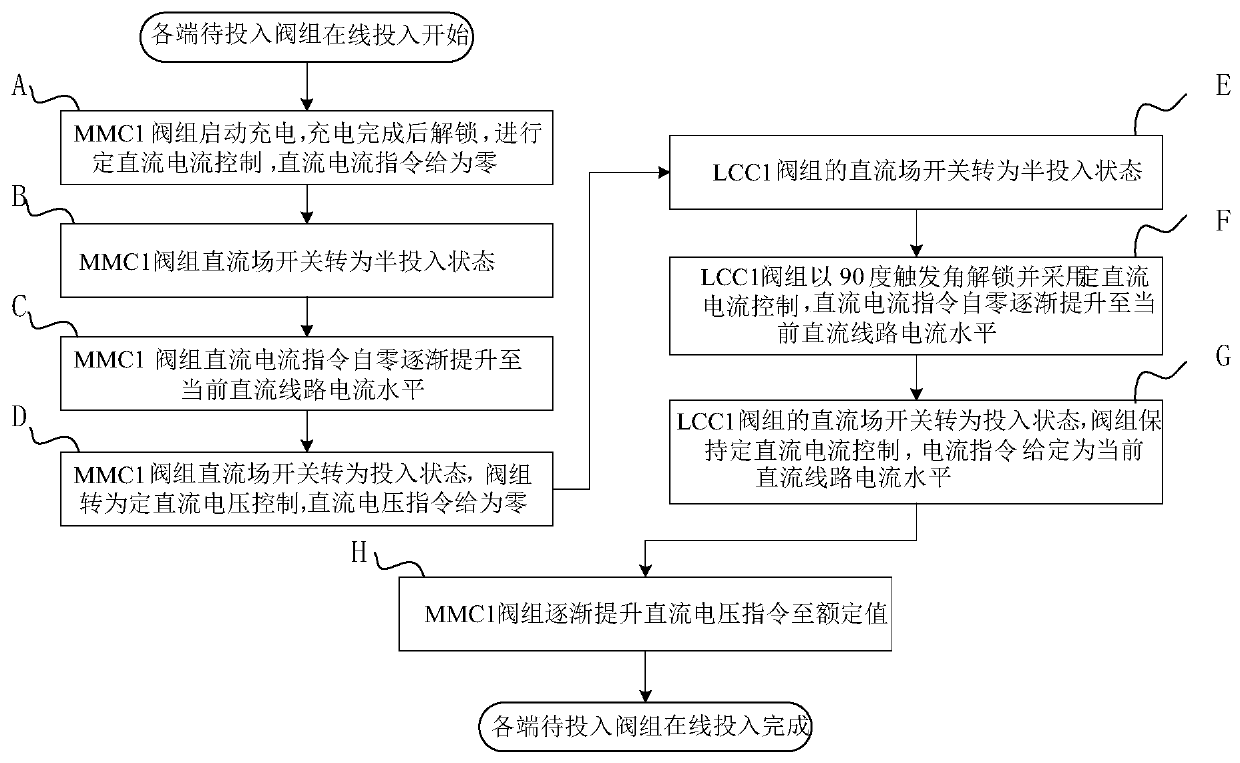

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

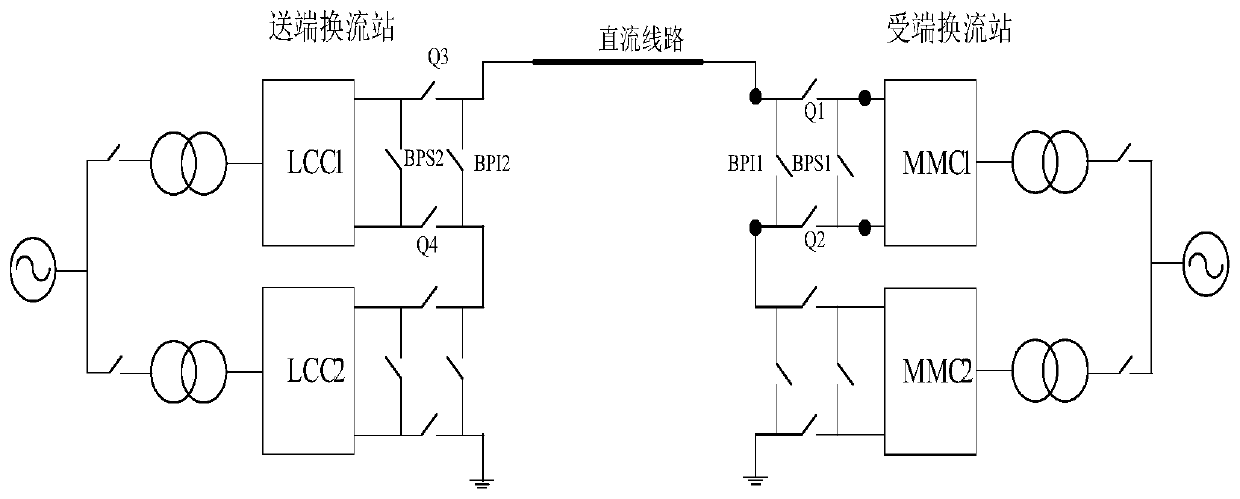

[0025] An LCC-MMC hybrid direct current transmission system, including a sending-end power grid, a sending-end converter station, a receiving-end converter station, a receiving-end power grid and a controller, the AC side of the sending-end converter station is connected to the sending-end power grid, The AC side of the end converter station is connected to the receiving end grid, the sending end converter station includes at least two LCC valve groups, the receiving end converter station includes at least two MMC valve groups, and the sending end converter station includes at least two LCC valve group, the DC side of each LCC valve group is cascaded connected, and each LCC valve group is equipped with a second DC field switch that controls the corresponding valve group to be turned on or off, and the DC side positive port of each LCC valve group i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com