Device for reducing ship navigation resistance and assisting in ship turning

A ship and resistance technology, applied in steering gear, ship propulsion, hull, etc., can solve the problems of reduced ship speed, limited minimum turning radius, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

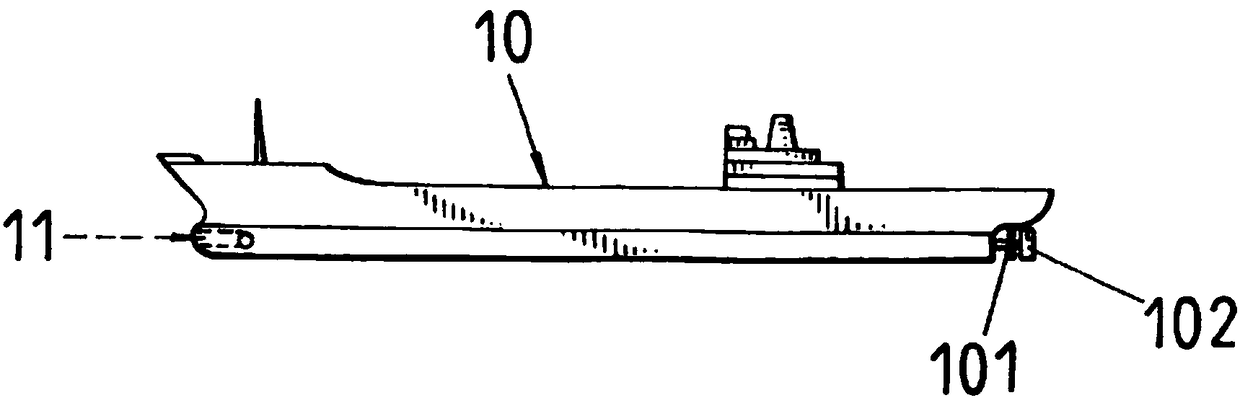

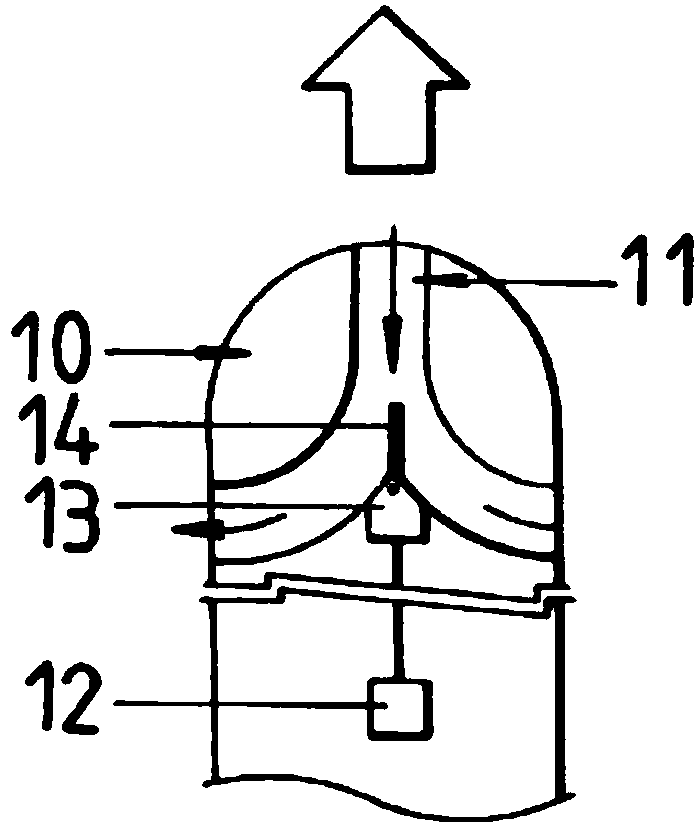

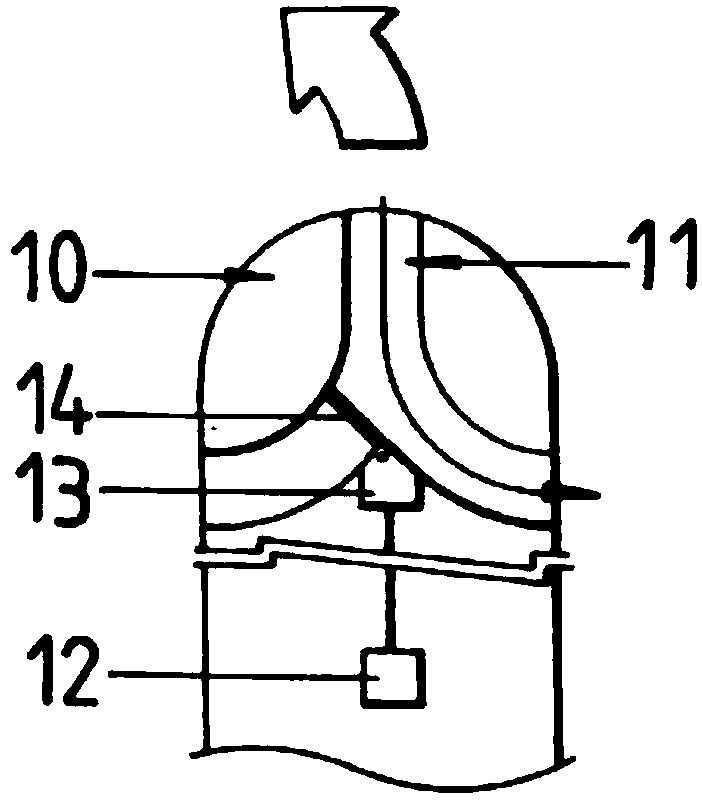

[0035] see figure 1 As shown, the present invention can reduce the ship navigation resistance and assist the ship turning device, except retaining the original screw propeller 101 and rudder plate 102 and other steering systems under the tail end of the ship 10; A three-way pipe 11 is set at the front end of the line, leading to the front of the bow and the outside of the hull on the left and right sides; The overall resistance of the ship 10 can be reduced to save fuel and reduce energy consumption; when steering is required, the water flow in the tee pipe 11 leading to both sides can be adjusted to assist steering.

[0036] Cooperate Figure 2 to Figure 5B As shown, the three-way pipe 11 is shaped like an "inverted Y" or "inverted T" structure. According to the principle of fluid mechanics, when the ship 10 is on the way, the water flow at the front end of the bow enters the three-way pipe 11. Distributing the flow to both sides of the ship 10 can reduce the overall resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com