Induction type garbage can cover structure

A technology of trash can and lid structure, applied in the field of daily necessities and trash cans, can solve the problems of damage to the internal parts of the opening mechanism, increase the failure rate of the induction trash can, and the speed of automatic opening and closing of the cover is slow. Maintenance cost, reasonable structure, and the effect of avoiding overvoltage damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

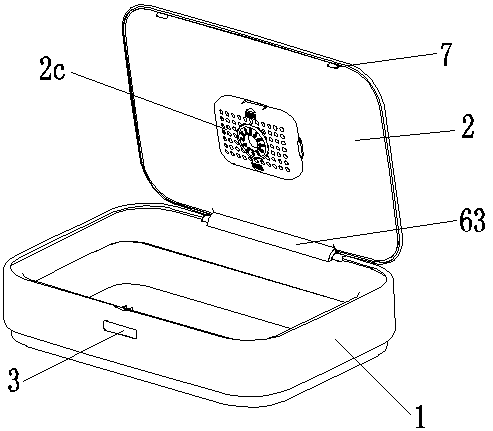

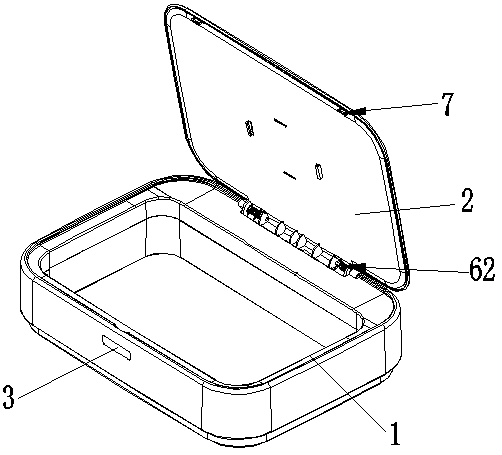

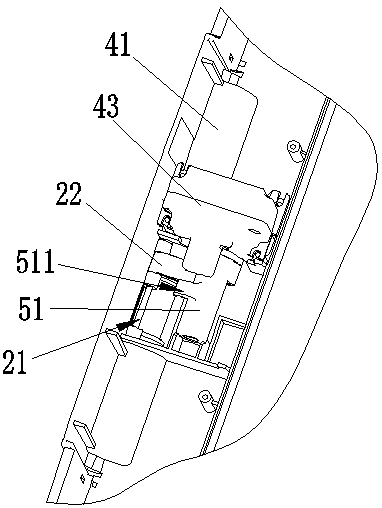

[0025] Such as Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0026] The reference signs therein are: trash can lid body 1, plastic base 11, plastic frame 12, hardware frame 13, cover plate 2, plastic panel 2a, hardware panel 2b, plastic box 2c, hinge shaft 21, hook 22 , hook pin 23, induction window 3, motor 41, gear box 42, first gear housing 42a, first gear housing 42b, central shaft 43, housing 51, housing 51a, end cover 51b, protruding hook 511, concave wheel 52 , Groove 52a, cam 53, convex surface 53a, spring 54, panel pin 61, torsion spring 62, protective cover 63, limit plate 63a, muffler pad 7.

[0027] Such as Figure 1 to Figure 6 as shown,

[0028] An inductive trash can cover structure, comprising a hingedly fitted trash can cover body 1 and a cover plate 2, the trash can cover body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com