Square lithium battery large surface appearance defect detection system and application method thereof

A technology of appearance defect and detection system, which is used in optical testing defects/defects, measuring devices, material analysis by optical means, etc., to avoid misjudgment and low work efficiency, avoid overvoltage damage, and improve the accuracy of appearance inspection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

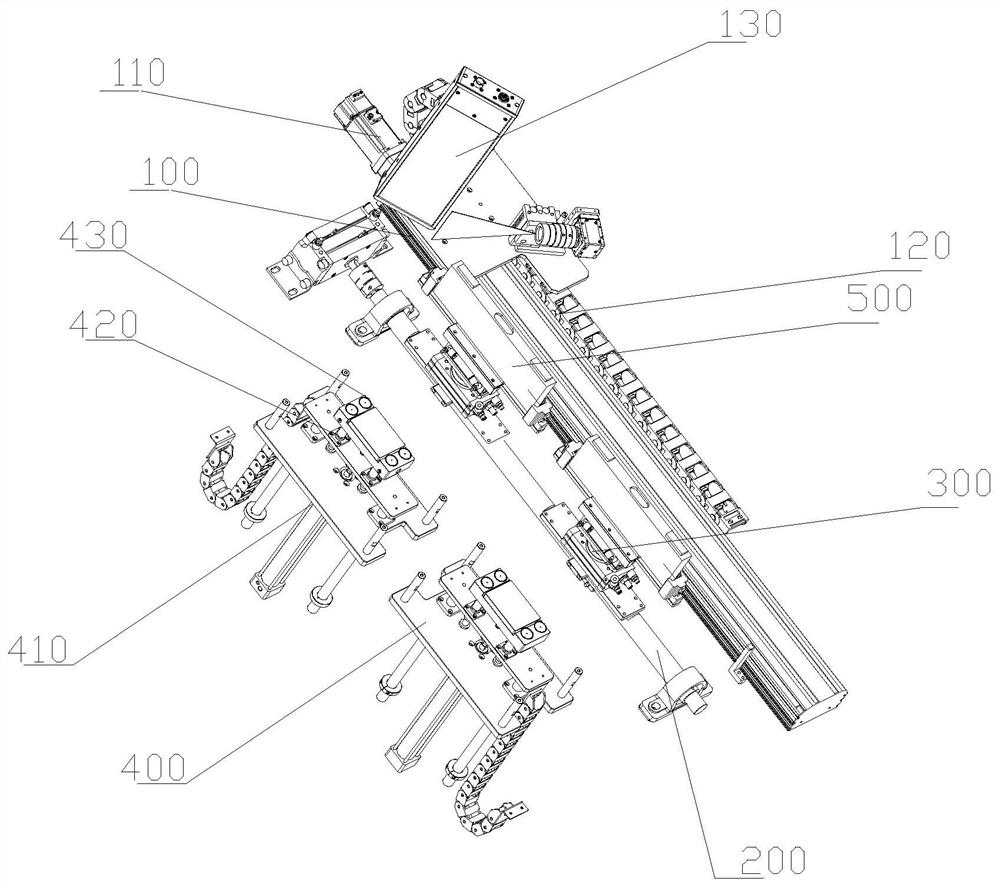

[0028] Embodiment 1 A large surface appearance defect detection system for a square lithium battery according to the present invention includes:

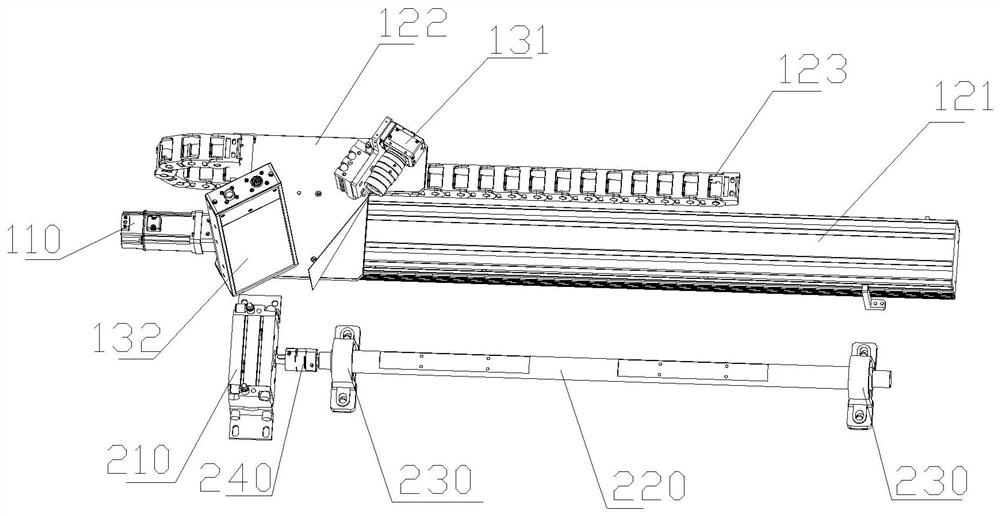

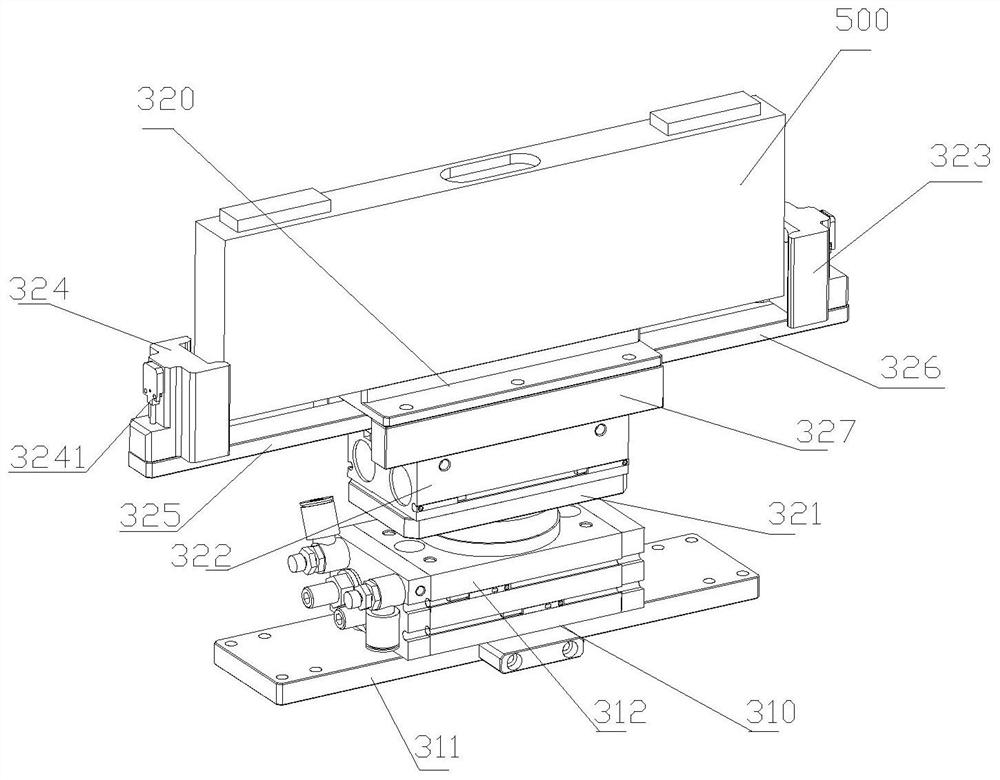

[0029] The large-surface detection mechanism 100 includes an X-direction drive device 110, a linear slide device 120, and a camera scanning assembly 130. The linear slide device 120 includes an X-direction guide part and an X-direction slide part, and the X-direction guide part is horizontally supported on the equipment On the installation surface, take the axial direction of the X-direction guide as the X direction; the X-direction drive device 110 is arranged at the end of the X-direction guide part, and the power output end of the X-direction drive device is connected to the X-direction drive device. The power input end of the guide guide is connected; the X-direction sliding part is installed on the X-direction guide and moves linearly along the axial direction of the X-direction guide under the drive of the driving device; the c...

Embodiment 2

[0041] Embodiment 2 According to the application method of a large surface appearance defect detection system of a square lithium battery according to the present invention, it includes the following steps:

[0042] S1 The battery positioning and rotating assembly 300 clamps and positions the delivered square lithium battery;

[0043] S2 After the square lithium battery is positioned, the 2.5D camera 131 moves in the X-axis direction through the action of the linear module 121, and then uses the 2.5D camera 131 to take pictures and scan the large surface features of the square lithium battery;

[0044] S3 After the code scanning is completed, the square lithium battery is rotated by 180° under the action of the battery positioning and rotating assembly 300, and then the 2.5D camera 131 is moved in the X-axis direction through the action of the linear module 121, and the square The other side of the lithium battery is photographed and scanned;

[0045] S4 After the code scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com