Intelligent stereoscopic warehouse with automatic storage function

A three-dimensional warehouse, intelligent technology, applied in the field of intelligent warehouse, can solve the problems of wasting time, unreasonable stacking of goods, difficulty in picking up goods, etc., to reduce costs, reduce human and financial resources, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below.

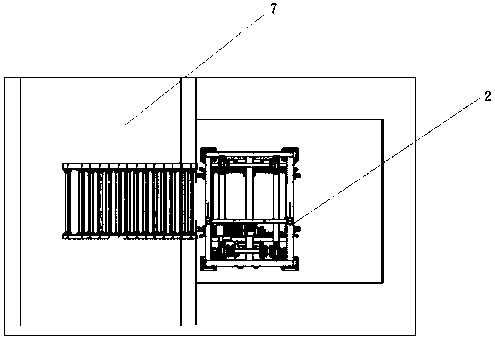

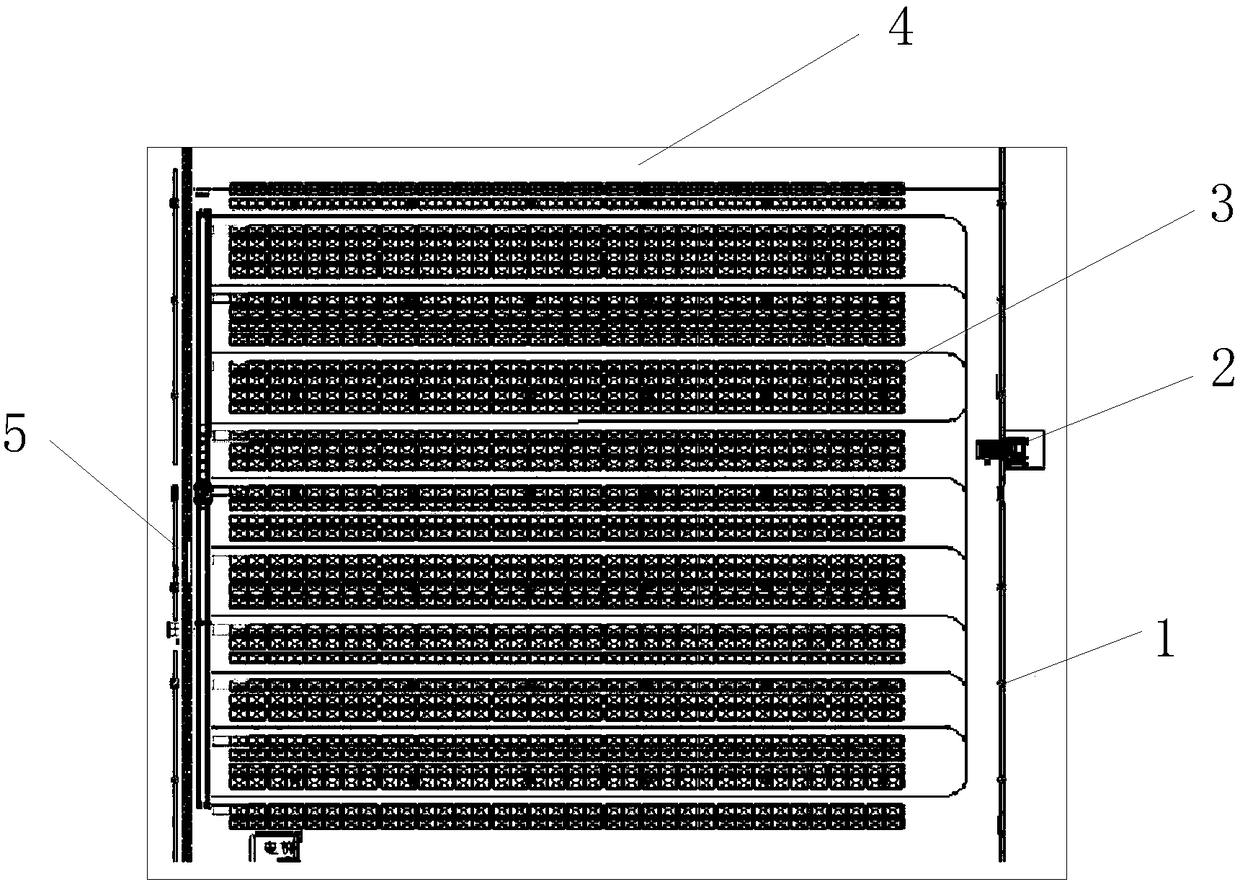

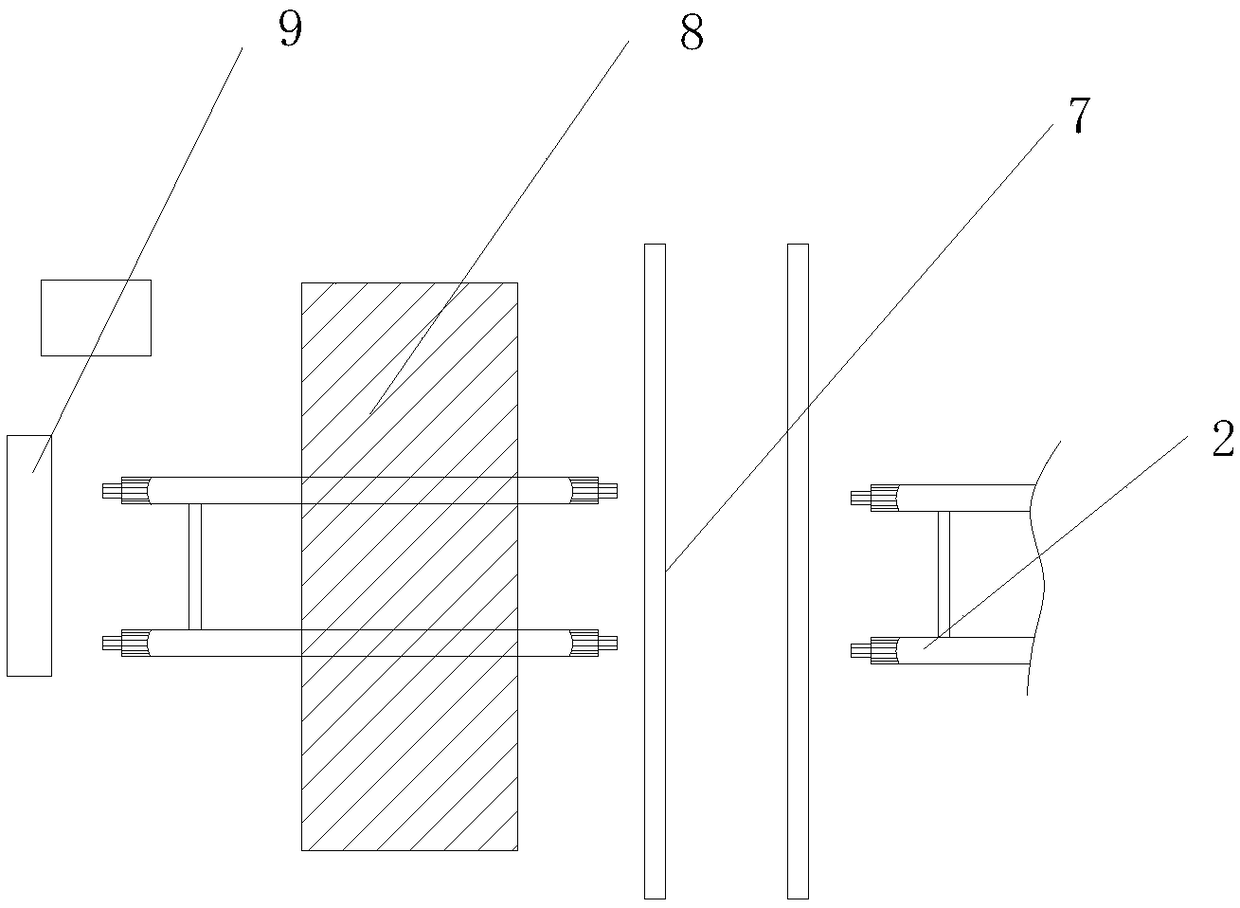

[0024] Please refer to figure 1 , figure 2 , image 3 , an intelligent three-dimensional warehouse for automatic storage, including a warehouse, a forklift, an automatic stacker 2 and a three-dimensional shelf 3, the warehouse is composed of a storage area 4, a storage area 5 and a storage area 6, and the three-dimensional shelves 3 are evenly arranged side by side Set in the storage area 5, the storage area 4 and the storage area 6 are respectively set at both ends of the three-dimensional shelf 3, the forklift puts the goods on the conveyor line 1 of the storage area 4, and the goods are transported after automatic code scanning Go to the three-dimensional shelf 3 in the storage area 5, and the automatic stacker 2 in the storage area 5 drives to the pick-up station under the instruction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com