Semiautomatic feeding device for engine valve seat rings

An engine valve, semi-automatic technology, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low feeding efficiency, high positive and negative misjudgment rate, high material jam rate, etc., and achieve cost reduction and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are described with reference to the above drawings.

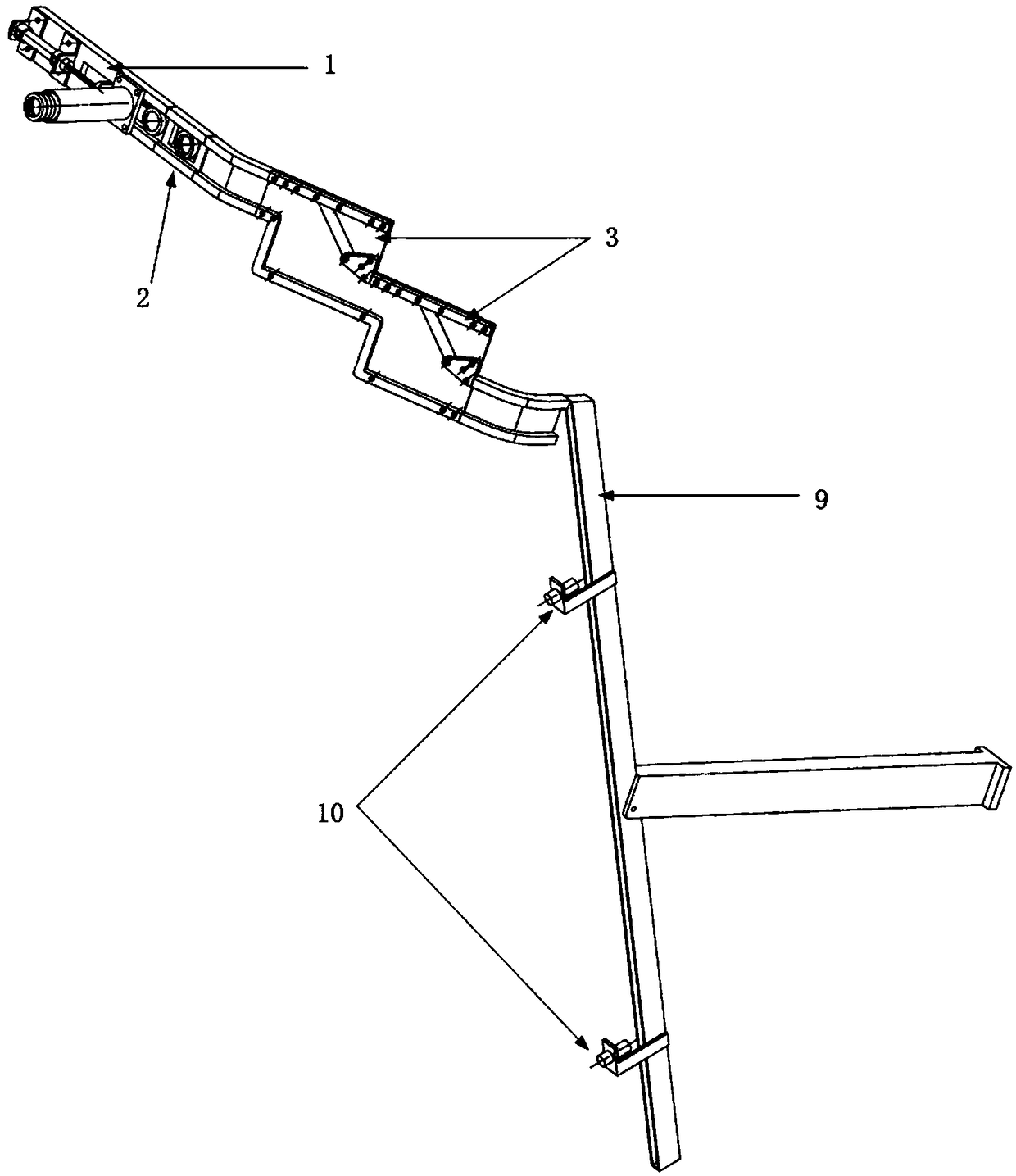

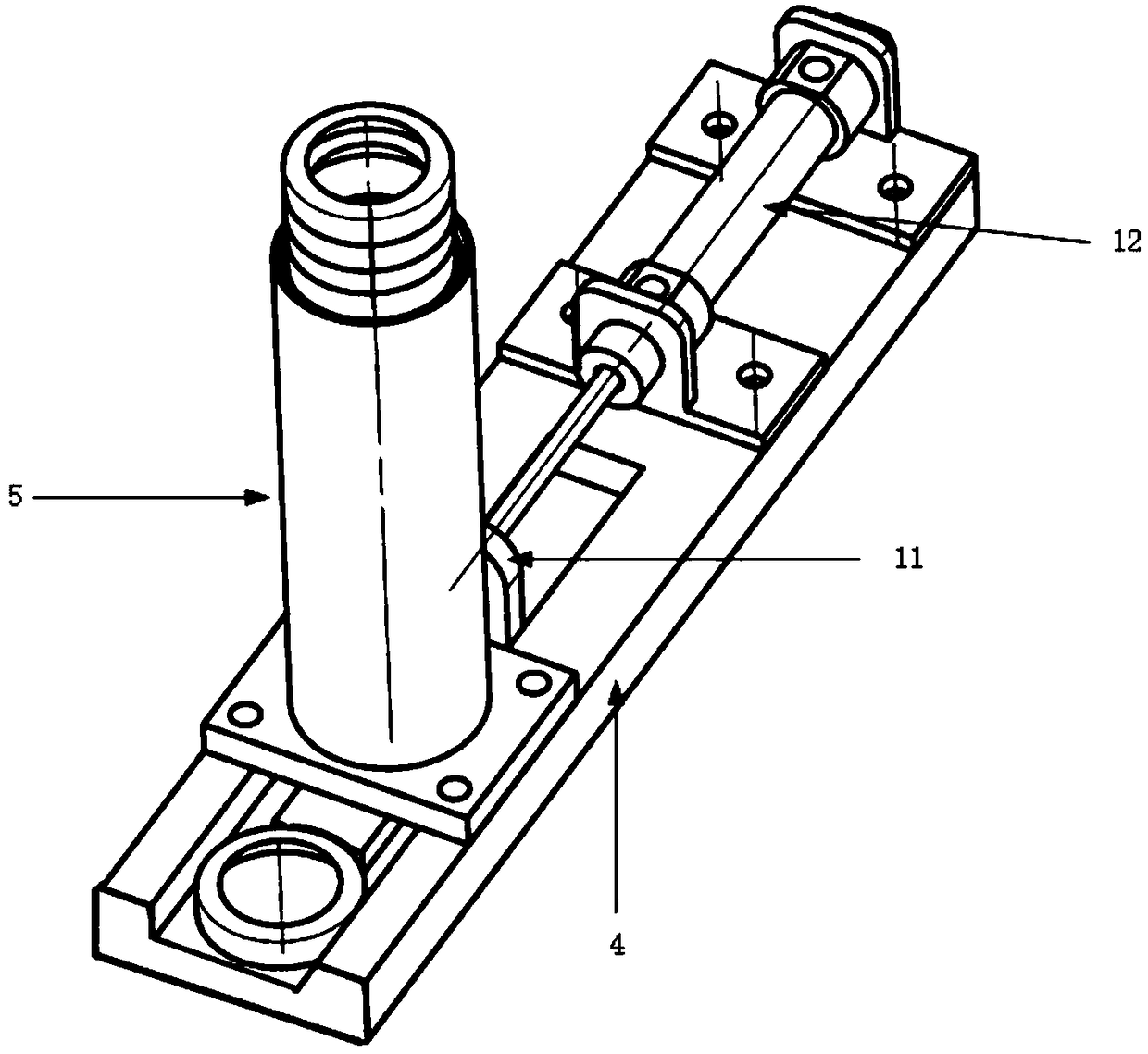

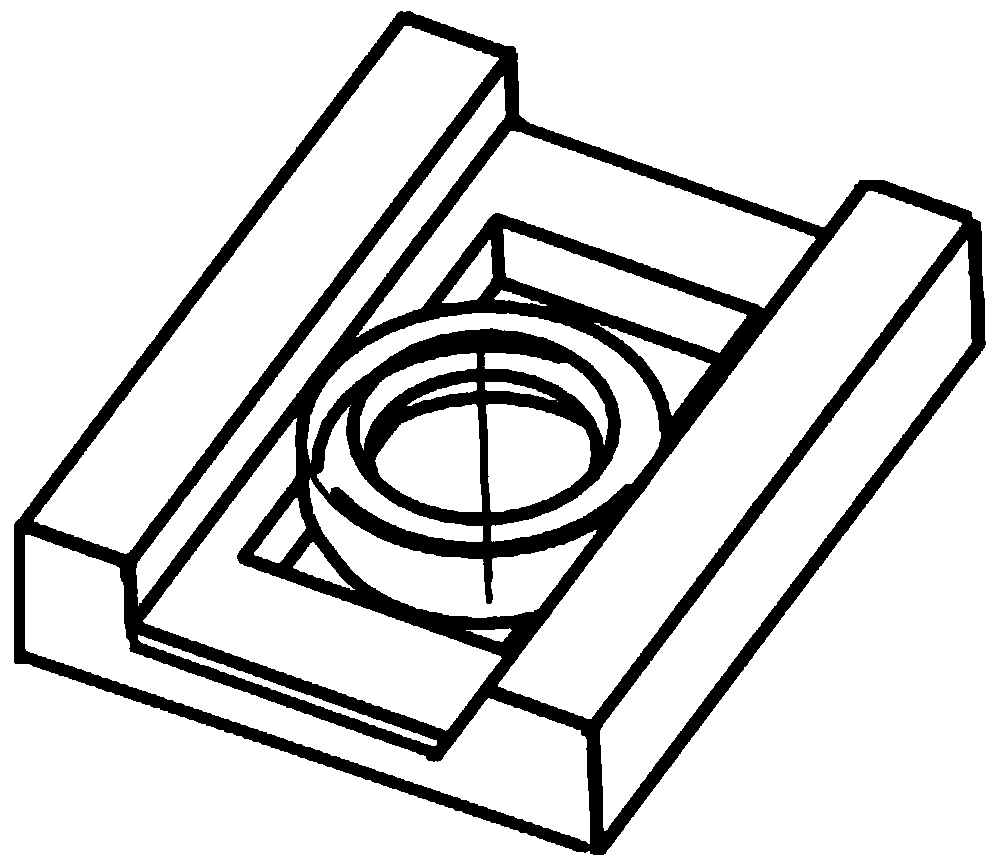

[0029] Depend on figure 1 It can be seen that the present invention provides a semi-automatic feeding device for engine valve seat rings, comprising a feeding mechanism 1, a size error prevention mechanism 2, and a positive and negative error prevention mechanism 3 connected in sequence. The feeding mechanism 1 includes a base 4, a barrel 5, Push material slide 11, driver 12, described barrel 5, described driver 12 and described push material slide 11 are arranged on the described base 4, and described push material slide 11 can be toward described barrel 5 direction Horizontal movement, the size error prevention mechanism 2 is a sliding channel, the positive and negative error prevention mechanism 3 includes at least one distribution channel 8, and also includes a material channel 9, a sensor 10, one end of the material channel 9 is connected to the positive In the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com