High-quality steel plate blank turnover device

A flipping device and slab technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of poor safety of the flipping device and collision damage of steel plates and slabs, and achieve simple structure, avoid collision damage, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

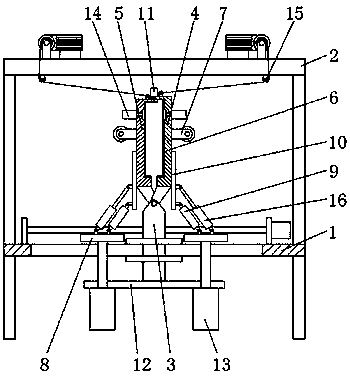

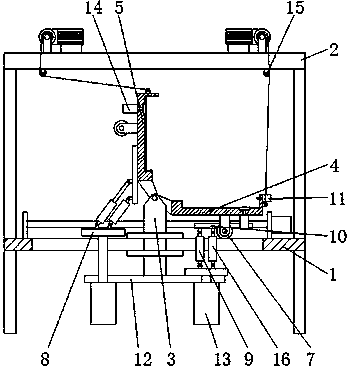

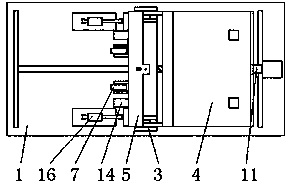

[0026] Embodiment: when using this device to carry out the overturning operation of the steel plate slab, one of them in the first overturning assembly 4 or the second overturning assembly 5 is first in a horizontal state through the traction assembly, and the other is in a nearly vertical state. Herein The first overturning assembly 4 is in the horizontal state as an example, the steel plate slab is placed in the slab placement groove of the slab placement seat 6 on the first overturning assembly 4, after placing, it is connected with the second overturning assembly 5 by control the traction assembly, the traction end is slowly released, and the second turning assembly 5 is gradually turned downwards and covered on the top of the first turning assembly 4. At this time, the ends of the two slab placing grooves 6 overlap each other and are locked The positions of the holes coincide, the locking cylinder 11 works, and the piston rod end of the locking cylinder 11 is inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com