Fixture for hoisting of high-voltage batteries for new-energy passenger vehicles

A high-voltage battery and new energy technology, applied in the field of hoisting tooling, can solve problems such as difficulty in hoisting high-voltage batteries of new energy buses, battery damage, casualties, etc., to facilitate assembly and transfer transmission, improve work efficiency, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

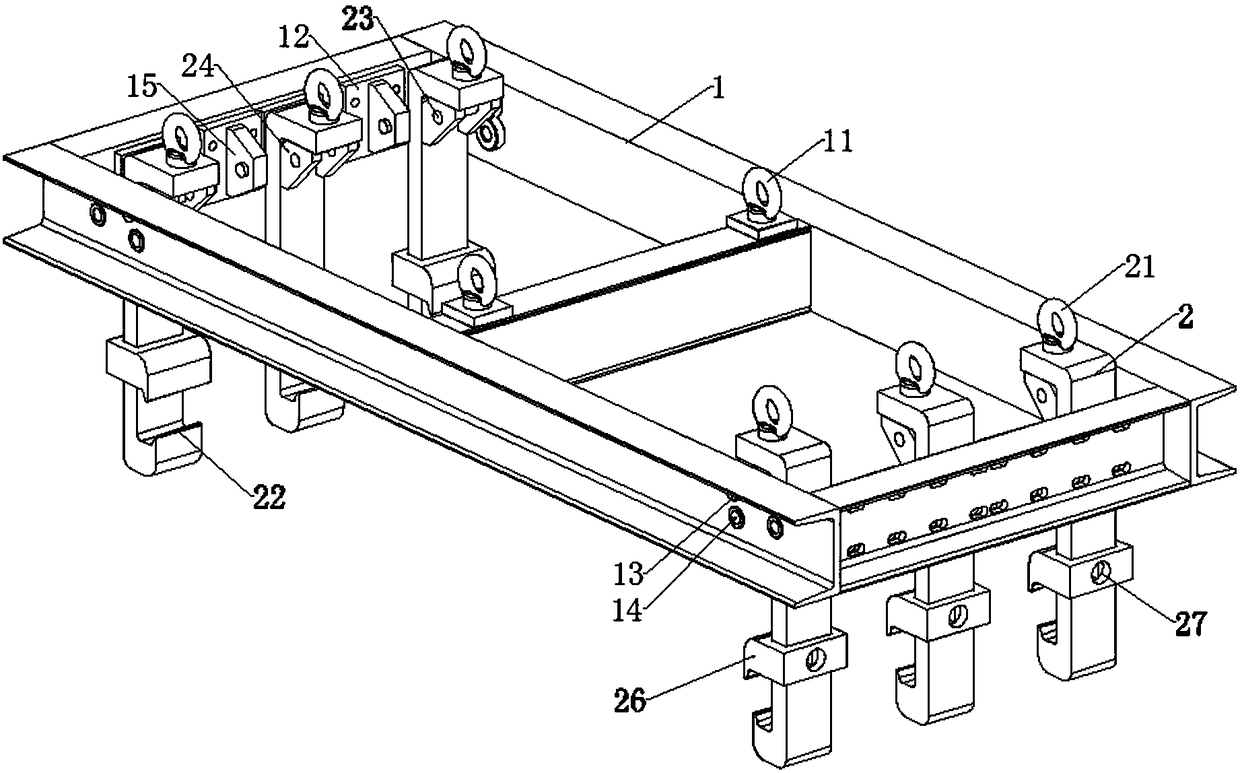

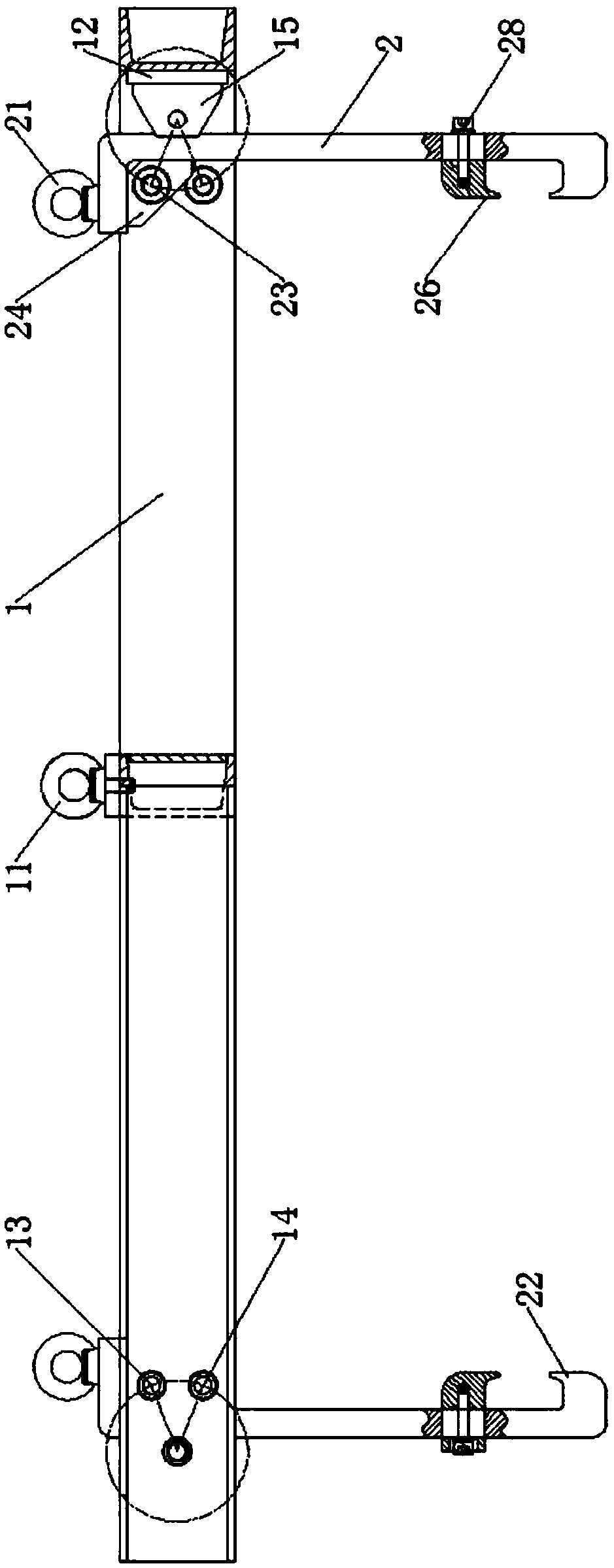

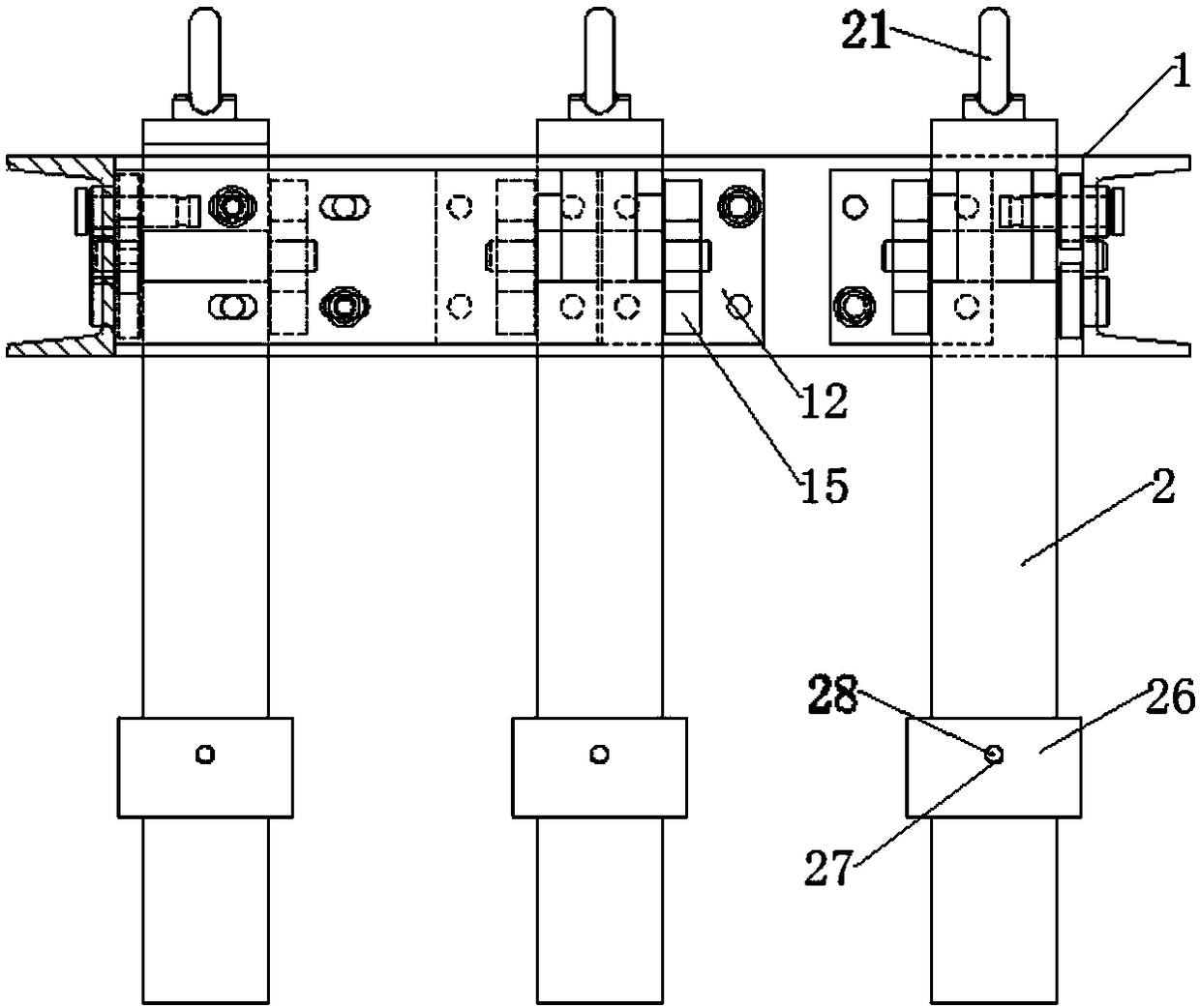

[0028] refer to Figures 1 to 7 As shown, the structural features of the tooling used for hoisting the high-voltage battery of the new energy bus are described in detail as follows:

[0029] A tool for hoisting a high-voltage battery of a new energy bus, which includes a spreader base 1, several spreaders 2 and several base suspension rings 11, and the base suspension rings 11 are arranged on the top of the spreader base 1 at intervals and symmetrically; The spreader base 1 is symmetrically fixed with several spreader support seats 12, and the spreader 2 is hinged with the spreader support seats 12; the top of the spreader 2 is provided with a spreader ring 21, and the spreader 2 The bottom is provided with a hook 22; and the hanger 2 and the hook 22 are integrally formed.

[0030] Wherein, the suspender base 1 is in the form of a "day" frame body, and the base suspension rings 11 are provided with two, and the base suspension rings 11 are symmetrically fixed on the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com