Reconstructed chromium slag powder for radiation-proof mortar and concrete, and preparation method and application thereof

A concrete and anti-radiation technology, which is applied in the field of building concrete materials, can solve the problems of consuming natural resources, unsuitable radioactive shielding, and high cost of aggregates, and achieve the effect of protecting environmental resources, improving structural strength and compactness, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

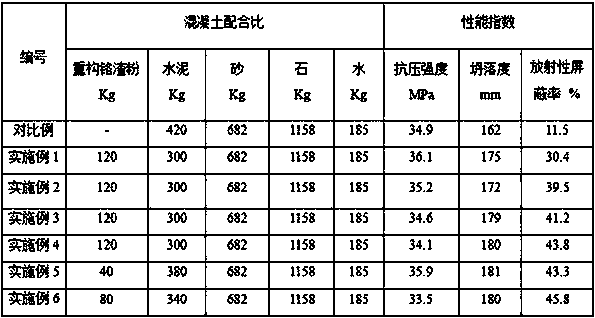

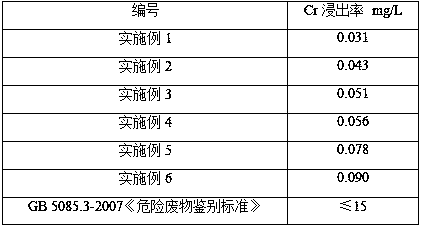

Examples

Embodiment 1

[0030] The raw material composition of the weight percentage of reconstituted chromium slag powder: 38% of chromium slag powder, 61% of molten slag, and 1% of catalytic fluxing component. The weight percent composition of the catalytic fluxing component is: 40% of red mud and 60% of vanadium slag.

[0031] The following steps are used to prepare the reconstituted chromium slag powder: 1) The chromium slag is first pulverized and then ground until the sieve residue of 80 μm is 18% to obtain chromium slag powder (the percentage content of Cr element oxide is 10%), and the ingredients are formulated according to the above ratio: chromium Slag powder 38%, molten slag 61%, catalytic fluxing component 1%.

[0032] 2) Wet chromium slag powder into balls with a moisture content of 10% and a diameter range of 5 to 10mm, and then dry them to a moisture content of 3% to form chromium slag powder balls for later use;

[0033] 3) Add chromium slag powder balls and catalytic flux component...

Embodiment 2

[0037] The raw material composition of the weight percentage of reconstituted chromium slag powder: 45% of chromium slag powder, 53% of molten slag, and 2% of catalytic fluxing component. The weight percent composition of the catalytic fluxing component is: 50% of red mud and 50% of vanadium slag.

[0038] The following steps are used to prepare the reconstituted chromium slag powder: 1) The chromium slag is first pulverized and then ground until the sieve residue of 80 μm is 15% to obtain chromium slag powder (the percentage content of Cr element oxide is 6%), and the ingredients are formulated according to the above ratio: chromium Slag powder 45%, molten slag 53%, catalytic fluxing component 2%.

[0039] 2) Wet chromium slag powder into balls with a moisture content of 8% and a diameter range of 10-20mm, and after balling, dry to a moisture content of 3% to form chromium slag powder balls for later use;

[0040] 3) Add chromium slag powder balls and catalytic flux componen...

Embodiment 3

[0044] The raw material composition of the reconstituted chromium slag powder in weight percentage: 50% of chromium slag powder, 47% of molten slag, and 3% of catalytic fluxing component. The weight percent composition of the catalytic fluxing components is as follows: 80% of red mud and 20% of vanadium slag.

[0045] The following steps are used to prepare the reconstituted chromium slag powder: 1) The chromium slag is first pulverized and then ground until the sieve residue of 80 μm is 20% to obtain chromium slag powder (the percentage content of Cr element oxide is 3%), and the ingredients are formulated according to the above ratio: chromium Slag powder 50%, molten slag 47%, catalytic fluxing component 3%.

[0046] 2) Wet chrome slag powder into balls with a moisture content of 10% and a diameter range of 10-15mm, and then dry them to a moisture content of 2% to form chromium slag powder balls for later use;

[0047] 3) Add chromium slag powder balls and catalytic flux co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com