Internal corner waterproof construction and construction technology thereof

A technology for inside corners and structures, applied in the field of inside corner waterproof structures and construction techniques, can solve the problems of inability to achieve waterproofing, anti-cold bridges, interface channeling, and failure of waterproofing systems, and achieve excellent construction application performance and good waterproofing. Performance, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

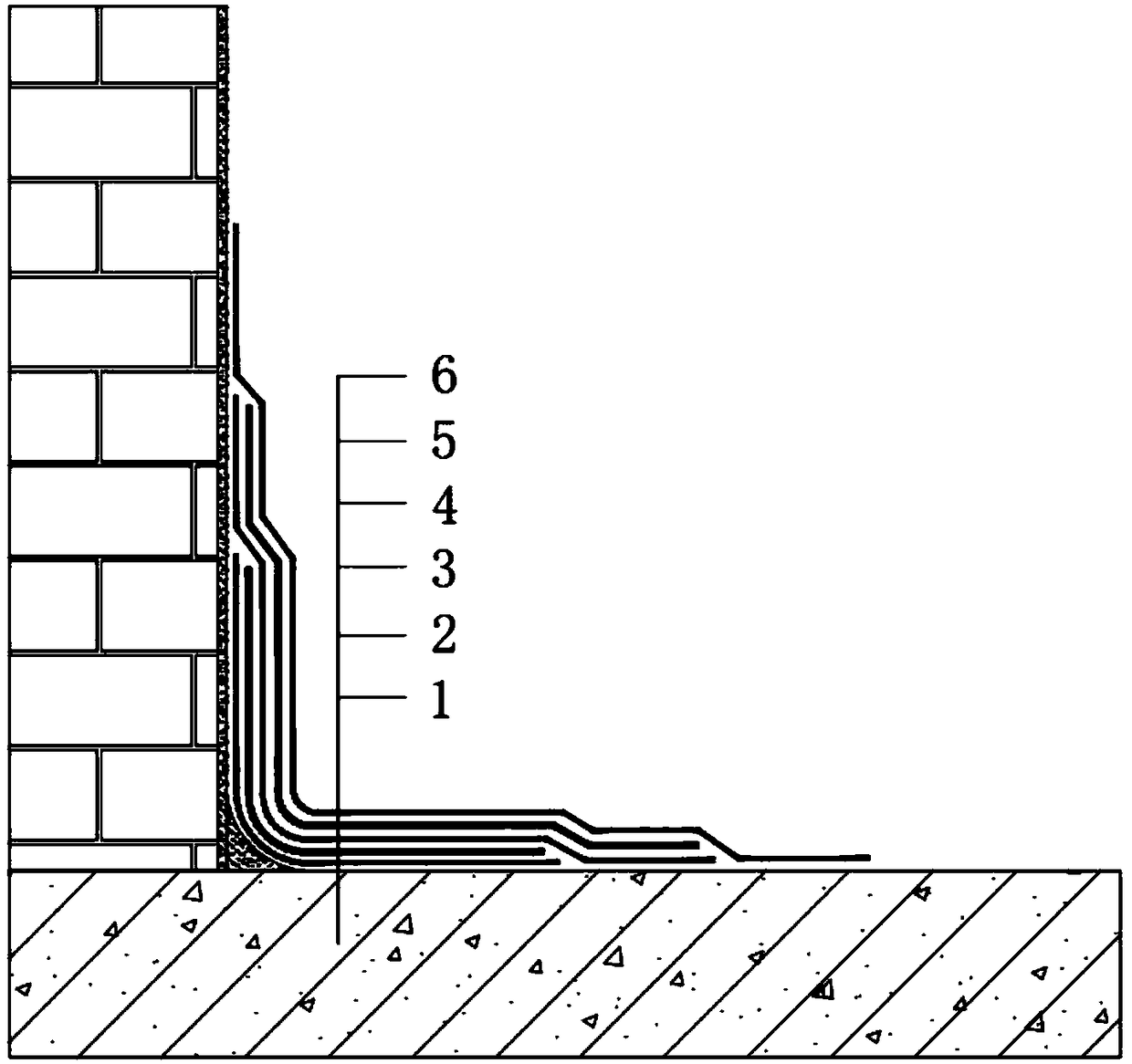

[0043] A kind of inner corner waterproof structure, which has a 2-layer structure, has a layer of carcass, and a layer of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0044] (1) Internal corner treatment: clean the base surface of the internal corner;

[0045] (2) Apply the first waterproof paint: paint the first rubber-like waterproof paint along the inner corner, the height of the wall surface is 5cm, and the ground is 5cm wider;

[0046] (3) Paving the first layer of carcass: Lay non-woven fabric on the first waterproof coating with a width of 10 cm, so that the non-woven fabric and the rubbery waterproof coating are in close contact and soaked.

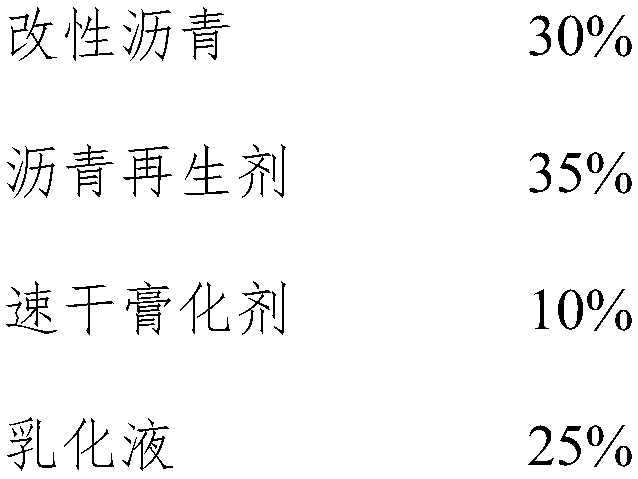

[0047] The rubbery waterproof coating used is rubbery waterproof coating A.

Embodiment 2

[0049] A kind of inner corner waterproof structure, has a 3-layer structure, has 1 layer of carcass, 2 layers of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0050] (1) Internal corner treatment: clean the base surface of the internal corner;

[0051] (2) Apply the first waterproof paint: paint the first rubber-like waterproof paint along the inner corner, the height of the wall surface is 2cm, and the ground is 2cm wider;

[0052] (3) Paving the first layer of carcass: laying non-woven fabric on the first waterproof coating, with a width of 4cm, so that the non-woven fabric is in close contact with the rubbery waterproof coating and soaked;

[0053] (4) Brush the second waterproof coating: brush the rubber waterproof coating on the non-woven fabric, so that the rubber waterproof coating is completely soaked and covers the non-woven fabric;

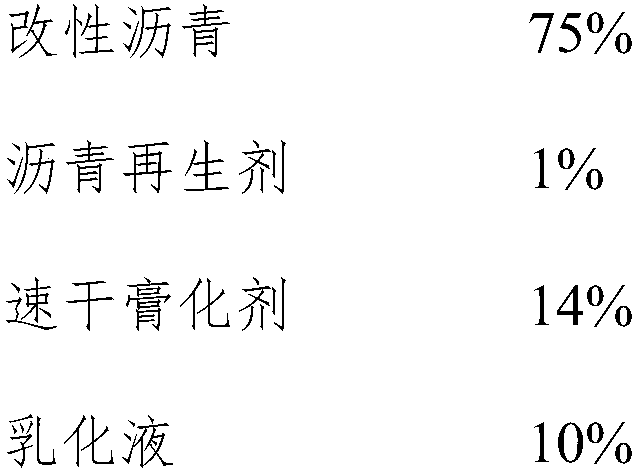

[0054] The application of the rubber-state waterproof paint and t...

Embodiment 3

[0057] A kind of inner corner waterproof structure, has a 3-layer structure, has 1 layer of carcass, 2 layers of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0058] (1) Internal corner treatment: clean the base surface of the internal corner;

[0059] (2) Apply the first waterproof paint: paint the first rubber-like waterproof paint along the inner corner, the height of the wall surface is 5cm, and the ground is 5cm wider;

[0060] (3) Paving the first layer of carcass: paving non-woven fabric on the first waterproof coating, with a width of 10 cm, so that the non-woven fabric is in close contact with the rubbery waterproof coating and soaked;

[0061] (4) Brush the second waterproof coating: brush the rubber waterproof coating on the non-woven fabric, so that the rubber waterproof coating is completely soaked and covers the non-woven fabric;

[0062] The application of the rubber-state waterproof paint and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com