Construction device and method for pouring and reinforcing sectional steel hoop type concrete single column

A construction device and hoop-type technology, applied in the direction of construction, building structure, formwork/template/work frame, etc., can solve the problems of installing a large number of fasteners, large consumption, affecting the construction progress, etc., to ensure the molding size and Look and feel, enhance compression resistance, reduce the effect of fastener consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

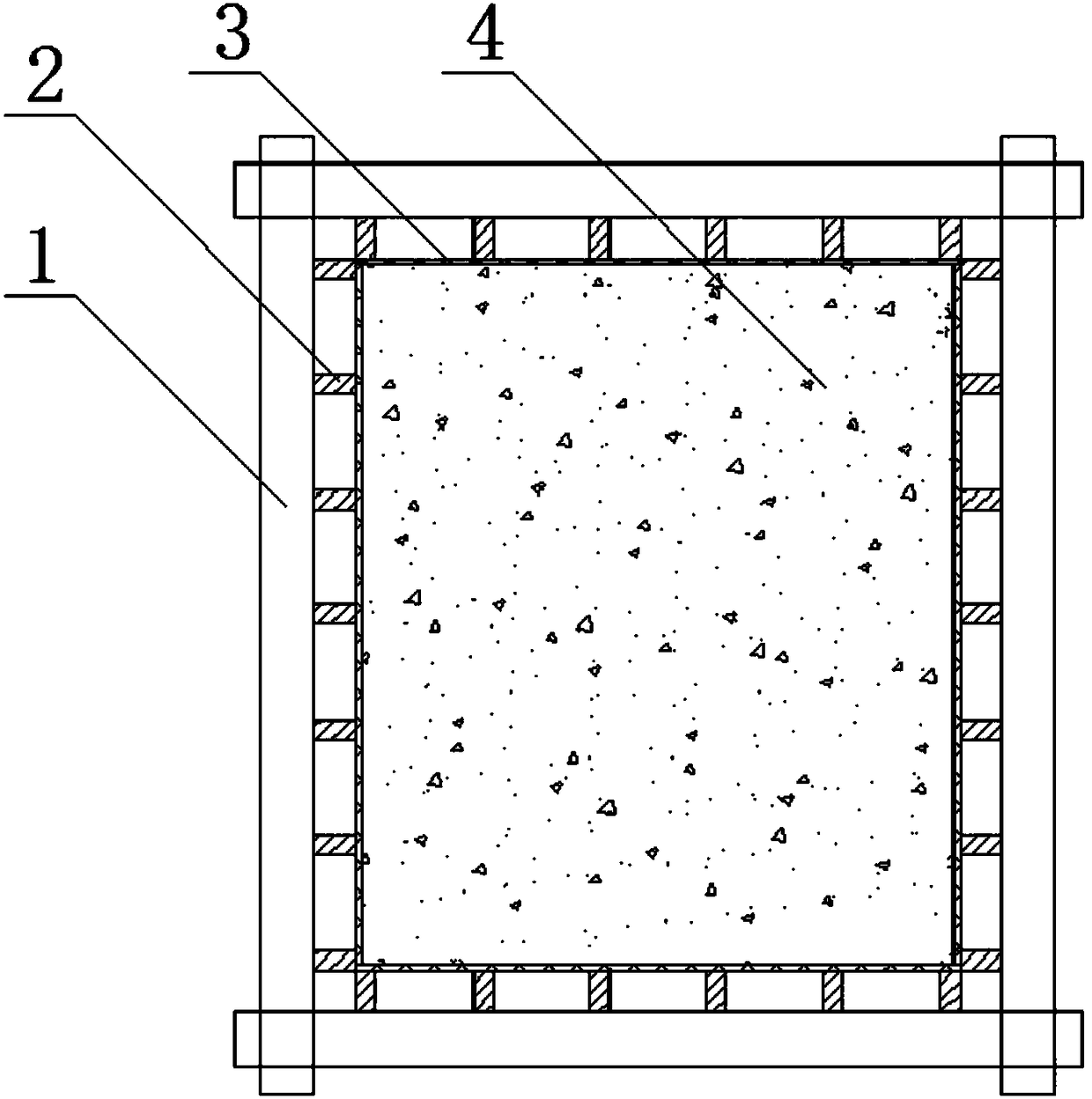

[0030] Such as Figure 1 to Figure 6 As shown, a type steel hoop type concrete single column 4 pouring reinforcement construction device, including steel components 1, wooden square 2, plywood 3 and plug-in 5;

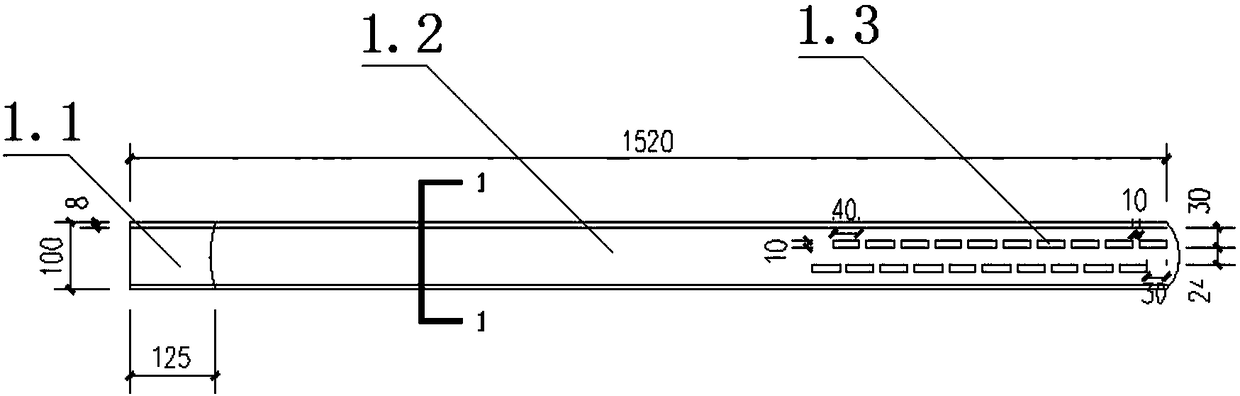

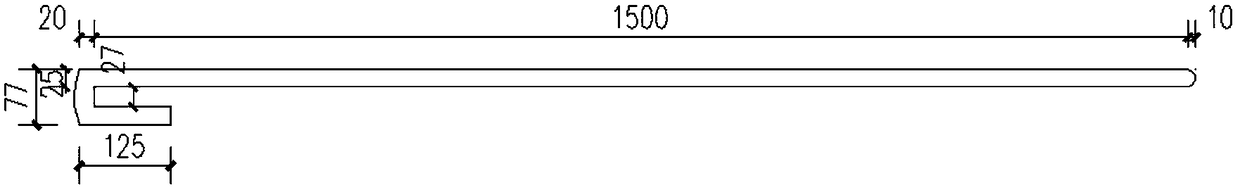

[0031] The shaped steel member 1 includes a shaped steel body 1.2 and a bent portion 1.1, and the shaped steel member 1 and the bent portion 1.1 are integrally formed;

[0032] Several jacks 1.3 are set on the steel body 1.2;

[0033] The lower end of the plug-in 5 is small and the upper end is large to ensure that the plug-in 5 can be inserted into the jack 1.3 but cannot pass through the jack 1.3;

[0034] The shaped steel hoop includes four shaped steel components 1 , and each shaped steel component 1 is connected at the end an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com