Special gear acceleration assembly connecting shaft

A technology for connecting shafts and gears, applied in the direction of belts/chains/gears, shafts, couplings, etc., can solve the problems of safety, stability, safety hazards, determining service life, shortening service life, etc., and achieve good overall structural strength, Safety and Stability Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

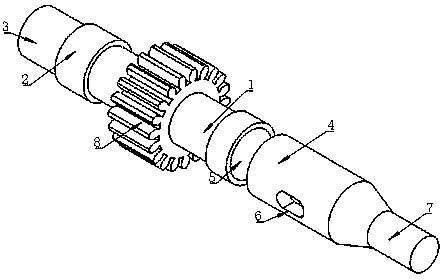

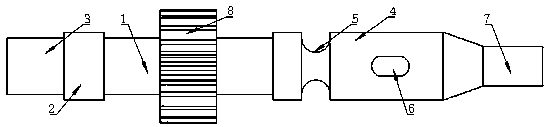

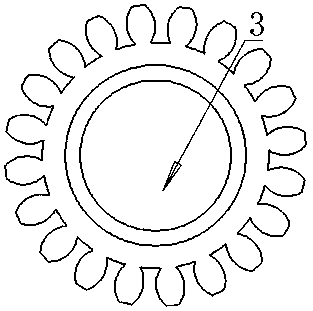

[0017] Such as Figure 1 to Figure 6 As shown, a special gear speed-up assembly connecting shaft, which can assemble two gear structures together at the same time. The central assembly hole of the center assembly and the assembly connection auxiliary support column of this part are connected and assembled together, which can meet the needs of a wider range of gear assembly, and the overall structural strength is better. The shock-absorbing assembly connection sealing ring is also installed between the two gears. The shock-absorbing treatment is performed on the middle position of the parts, so that the safety and stability of the gear assembly structure at each position are more reliable when used, and the safety of the high-speed rotating gear is more guaranteed when used, so that the use of the gear structure The scope is wider, and when this part is assembled with the mechanical structure, the assembly operation is more convenient through the positioning columns at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com