A kind of cross-linked composite membrane for liquid flow battery and its preparation and application

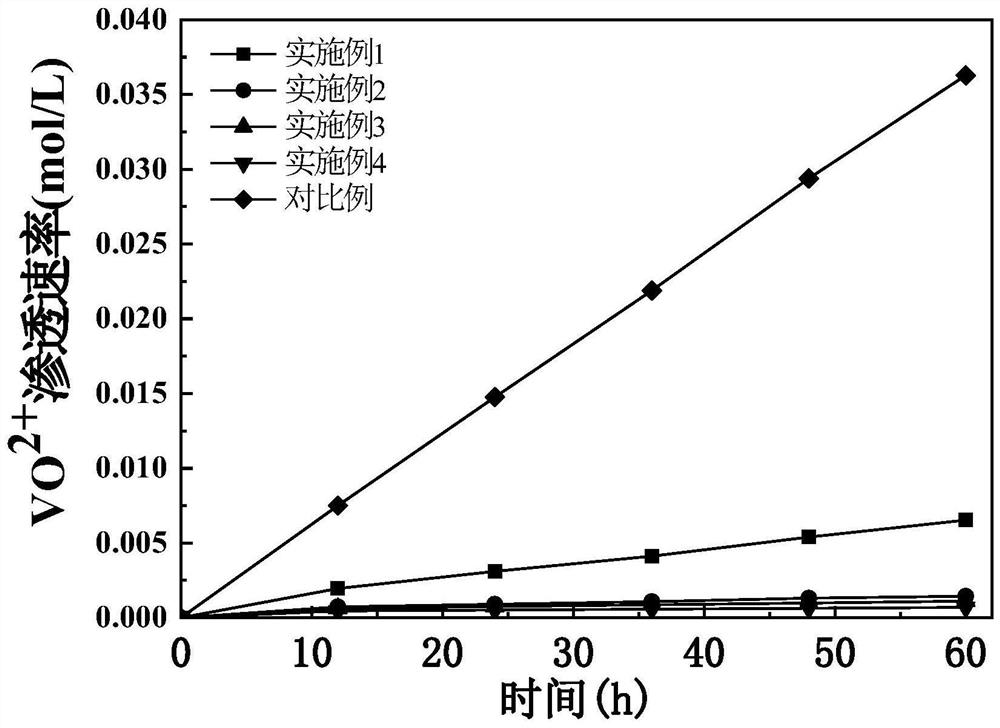

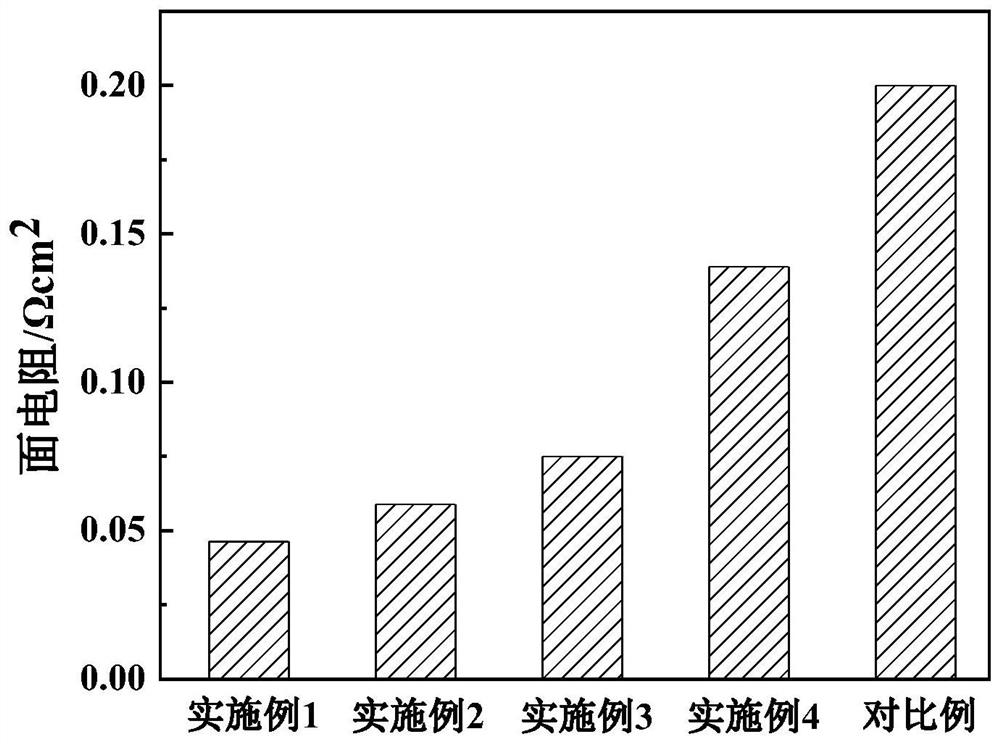

A flow battery and composite membrane technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of low conductivity and poor selectivity of all-vanadium flow battery membranes, and achieve high ionic conductivity, thickness and density. The effect of controllable degree and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

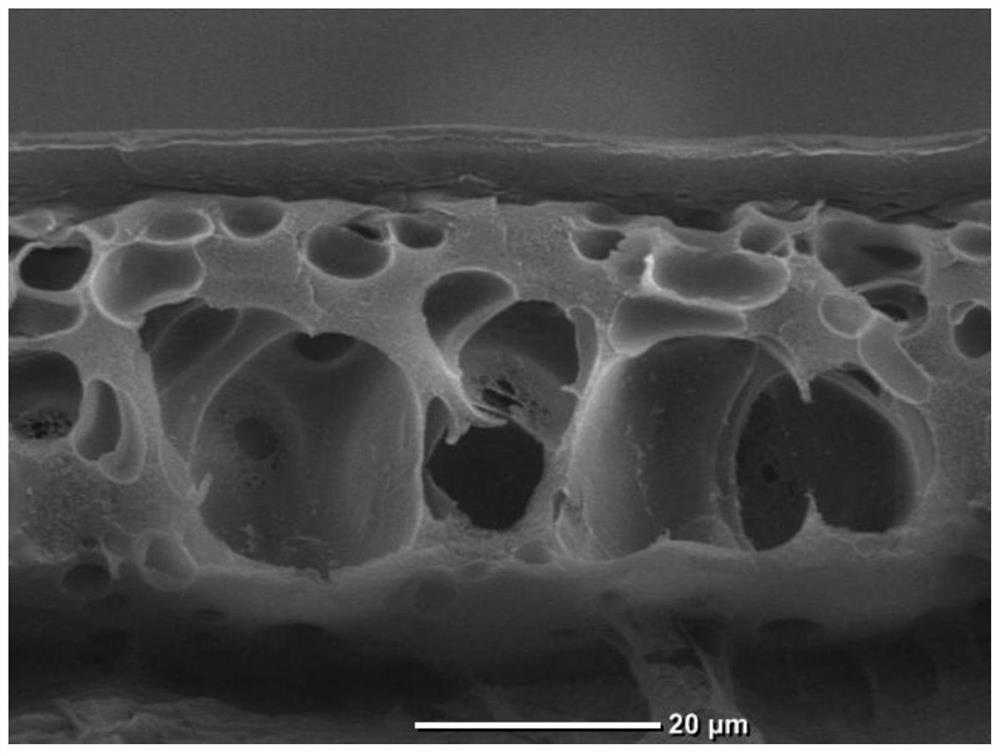

[0027] 6 g of polybenzimidazole (PBI) was dissolved in 44 g of DMAc and stirred at room temperature for 48 hours to form a polymer solution. Dissolve 0.5g of terephthaloyl chloride in 500ml of n-heptane to form a homogeneous solution, spread the polymer solution on a glass plate, volatilize the solvent for 5s, then immerse the glass plate in the homogeneous solution for 1min, and then transfer In the water tank filled with 25 ℃ deionized water and completely submerged until it solidifies and forms a film, a dense separation layer composed of chemically crosslinked polymer chains and a non-crosslinked support layer (pore size distribution 100-200nm) with a loose porous structure are obtained. Composite membrane, the separation layer thickness is 3±0.5um, the membrane porosity is about 75%, and the membrane thickness is 40±5μm. Soak in 3mol L-1 sulfuric acid solution before use.

Embodiment 2

[0029] 7.5g of polybenzimidazole (PBI) was dissolved in 42.5g of DMAc and stirred at room temperature for 48 hours to form a polymer solution. Dissolve 0.8g of isophthaloyl chloride in 500ml of n-heptane to form a homogeneous solution, spread the polymer solution on a glass plate, volatilize the solvent for 5s, then immerse the glass plate in the homogeneous solution for 2min, then transfer In the water tank filled with 25 ℃ deionized water and completely submerged until it solidifies and forms a film, a dense separation layer composed of chemically crosslinked polymer chains and a non-crosslinked support layer (pore size distribution 100-200nm) with a loose porous structure are obtained. Composite membrane, the separation layer thickness is 4±0.5um, the membrane porosity is about 70%, and the membrane thickness is 40±5μm. Soak in 3mol L-1 sulfuric acid solution before use.

Embodiment 3

[0031] 8.5g of polybenzimidazole (PBI) was dissolved in 41.5g of DMAc and stirred at room temperature for 48 hours to form a polymer solution. Dissolve 0.5g of 1,3,5-benzenetricarboxylic acid chloride in 500ml of n-heptane to form a homogeneous solution, spread the polymer solution on a glass plate, evaporate the solvent for 5 seconds, and then immerse the glass plate in the homogeneous solution 5min, then transferred to a water tank filled with 25°C deionized water and fully submerged until solidified to form a film, to obtain a dense separation layer composed of chemically crosslinked polymer chains and a non-crosslinked support layer with a loose porous structure (pore size distribution 100 -200nm) composite membrane, the separation layer thickness is 4±0.5um, the membrane porosity is about 71%, and the membrane thickness is 40±5μm. Soak in 3mol L-1 sulfuric acid solution before use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com