Double-fold arm segment assembly machine for tunnel shield machine with three-ring section

A segment assembly machine and segment assembly technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problem of the special shape of the three-ring section tunnel and the inability of the segment assembly machine to meet the requirements of the three-ring section tunnel shield machine. Pieces assembly and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

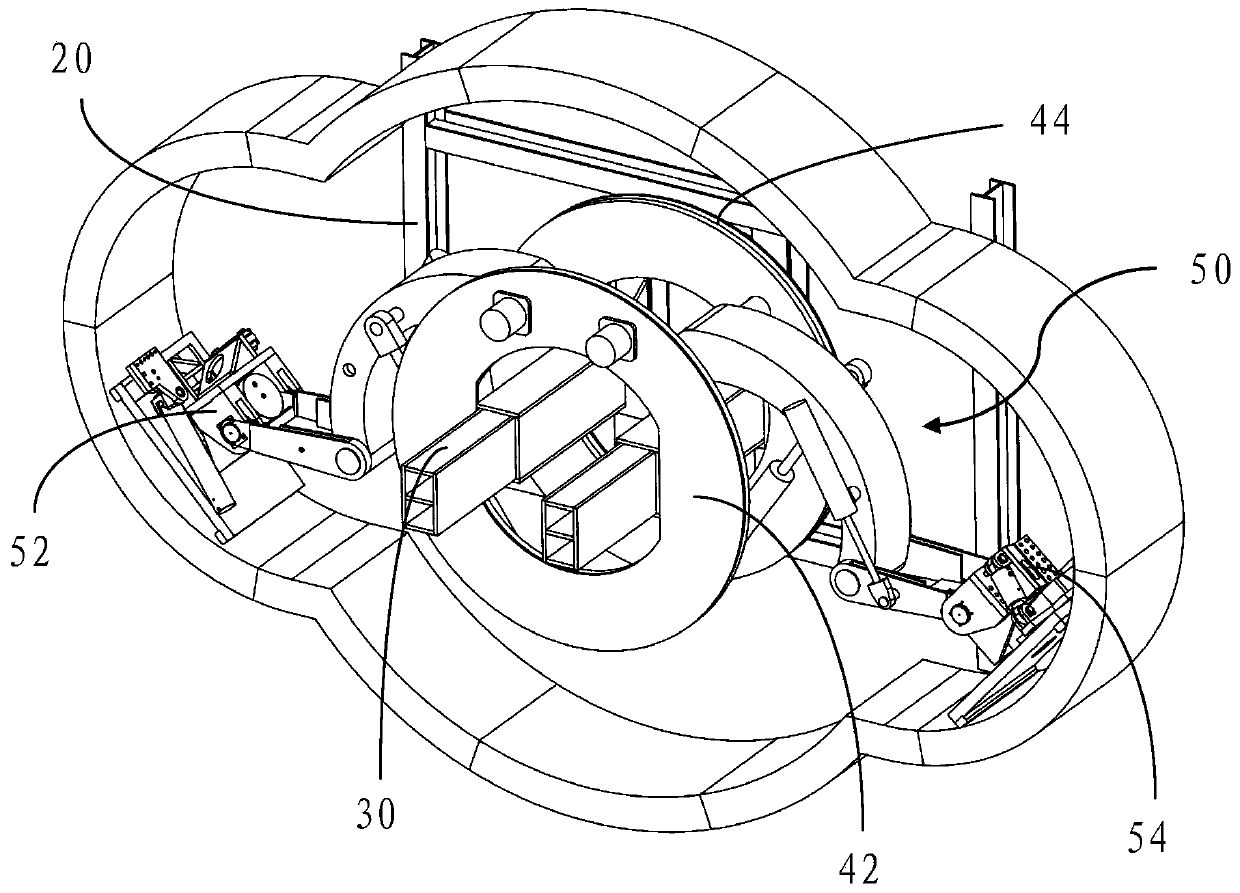

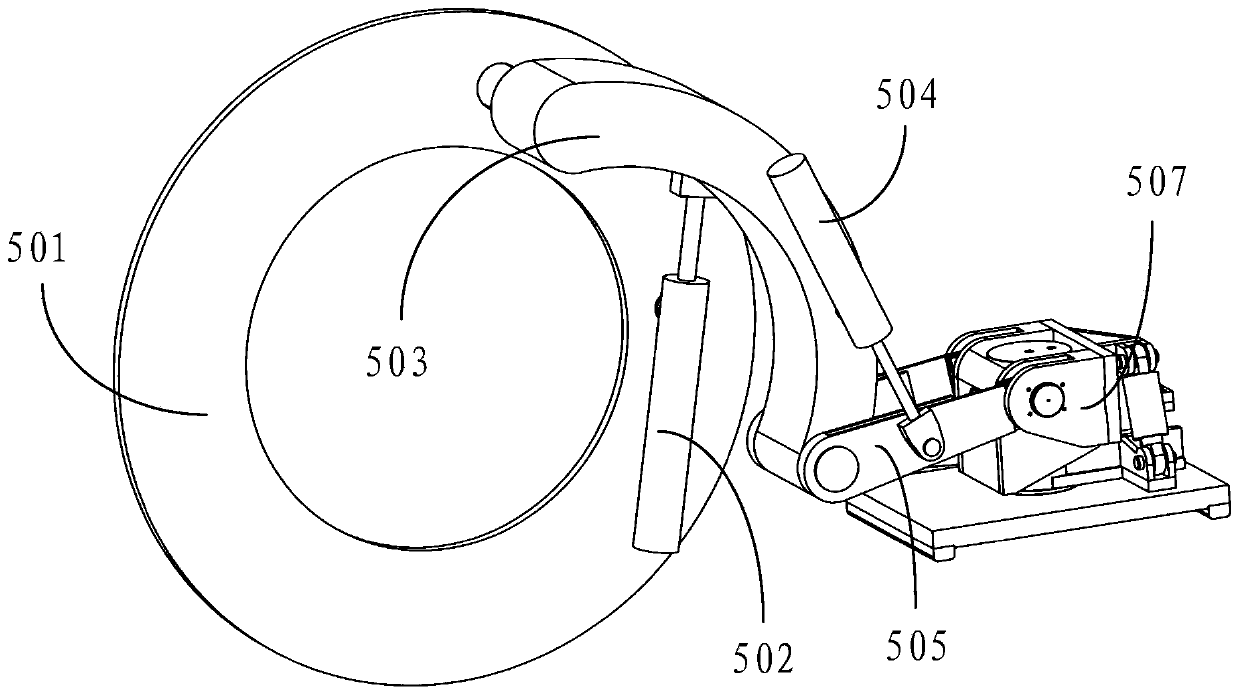

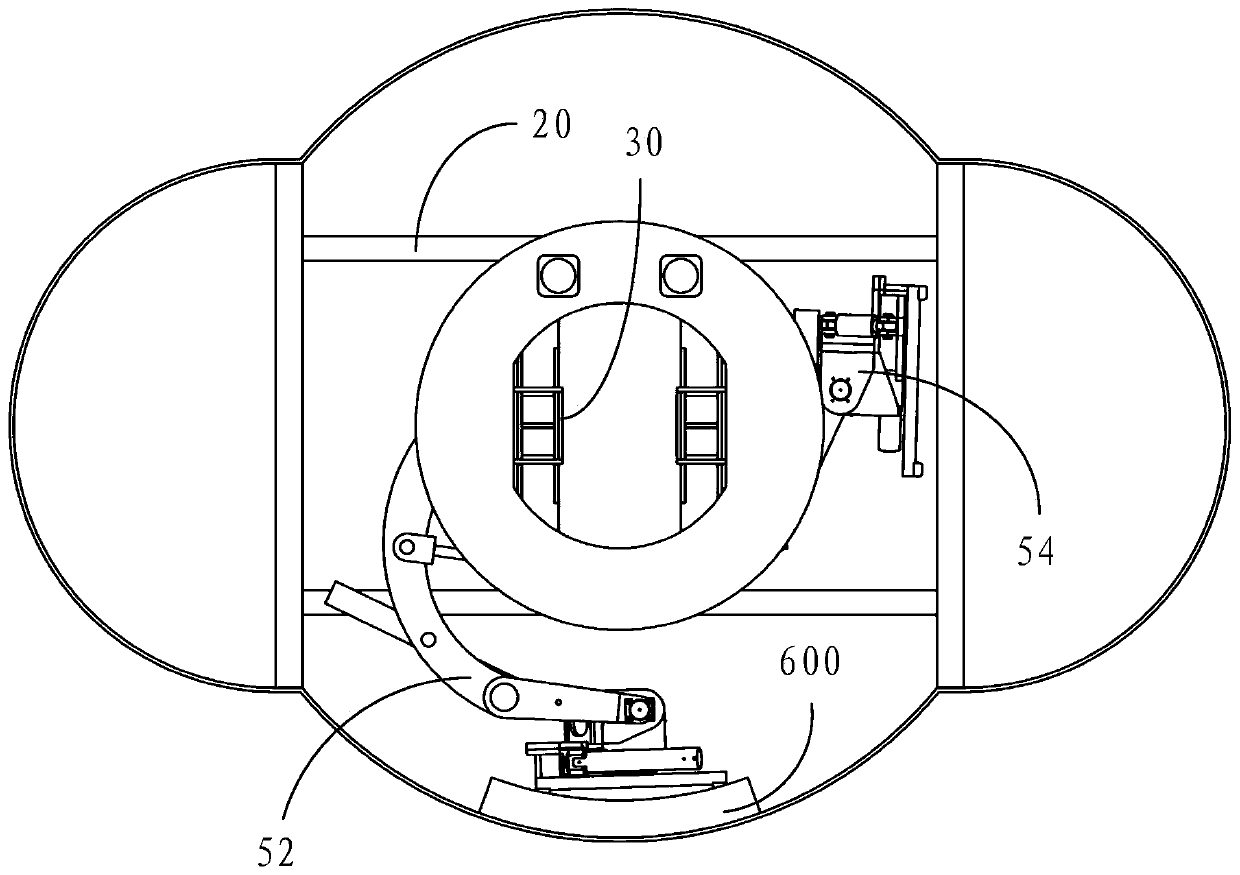

[0031] Refer to figure 1 As shown, the double folding arm tube segment assembly machine of the three-ring section tunnel shield machine of the present invention includes a support frame 20, a slewing support 30, a front rotation drive 42, a rear rotation drive 44, and a folding arm tube segment assembly machine 50. The support frame 20 is vertically arranged and installed in the shield machine. The support frame 20 is equipped with two horizontally arranged slewing supports 30. The front slewing drive 42 and the rear slewing drive 44 are installed in parallel to the slewing support. On the support 30, and the rear slewing drive 44 is close to the support frame 20, the front slewing drive 42 is located on the other side of the rear slewing drive 44 opposite to the support frame 20. In addition, the front slewing drive 42 and the rear slewing drive 44 eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com