Vertical transmission method of gearbox for rail transit and vertical transmission gearbox

A rail transit and gear box technology, applied in transmission boxes, transmission parts, gear lubrication/cooling, etc., can solve the problem that the traction motor and gear box have no installation location, the gearbox and traction motor have no installation space, and the traction motor and gear The installation space of the box is small and other problems, so as to achieve the effect of saving installation space, compact structure and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

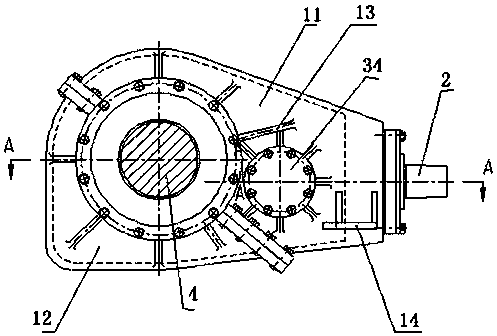

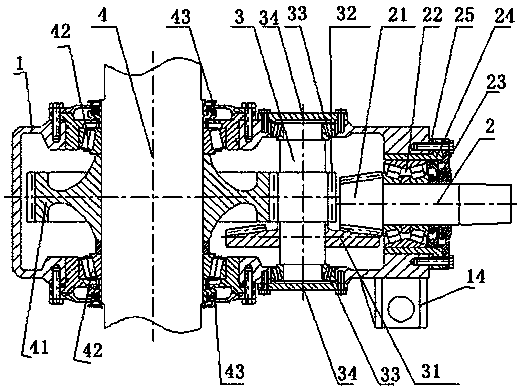

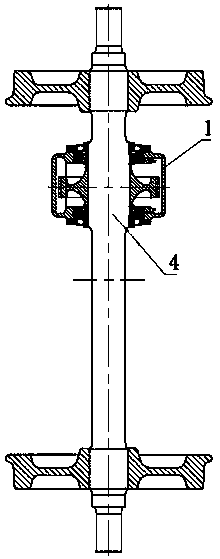

[0038] Such as Figure 1-3 As shown, a vertical transmission gearbox for rail transit adopts a two-stage transmission mode, including a gear box body 1, the gear box body 1 is used as the installation main body, and a fixing device is arranged inside, and the transmission device is installed on the gear box through the fixing device Body 1. Transmit the movement of the traction motor to the axle to drive the train forward. The fixing device includes an input fixing device, an intermediate fixing device and an output fixing device, and the input shaft, the intermediate shaft and the output shaft are mounted on the gear case 1 through the fixing device, the intermediate fixing device and the output fixing device respectively.

[0039] The input fixing device includes an input bearing seat and an input bearing arranged in the input bearing seat. The input bearing is installed on the end of the gearbox body 1 through the input bearing seat. The input shaft 2 passes through the hole ...

Embodiment 2

[0044] Such as figure 2 As shown, in this embodiment, an oil collecting tank and a lubricating oil passage are provided in the gear box body 1, and the gears and bearings are lubricated by splash lubrication to ensure that each gear and bearings are sufficiently lubricated.

Embodiment 3

[0046] Such as figure 2 As shown, in this embodiment, the bearing bush and the end face of the gear box 1 are provided with an adjusting pad 25, which can precisely adjust the axial position of the input shaft 2, thereby adjusting the bevel gear backlash of the first-stage transmission, so that Bevel gear one 21 and bevel gear two 31 are in the best meshing state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com