Self-locking valve

A technology of self-locking valve and valve body, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problem of low consistency of action, and achieve the effect of realizing intelligent control, ensuring accuracy and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

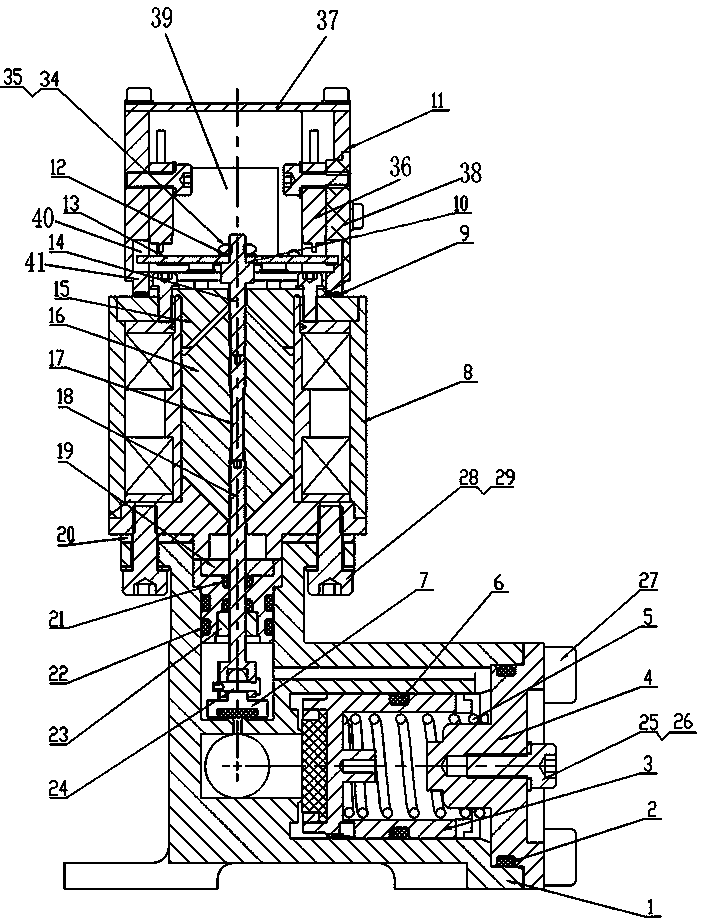

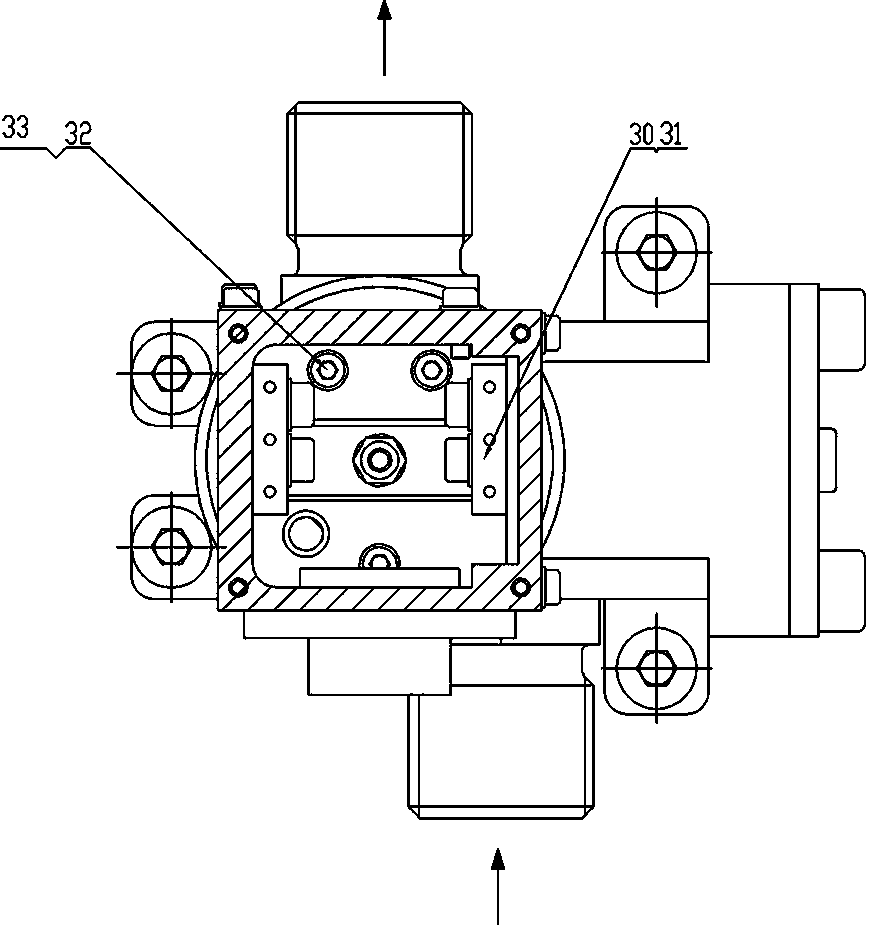

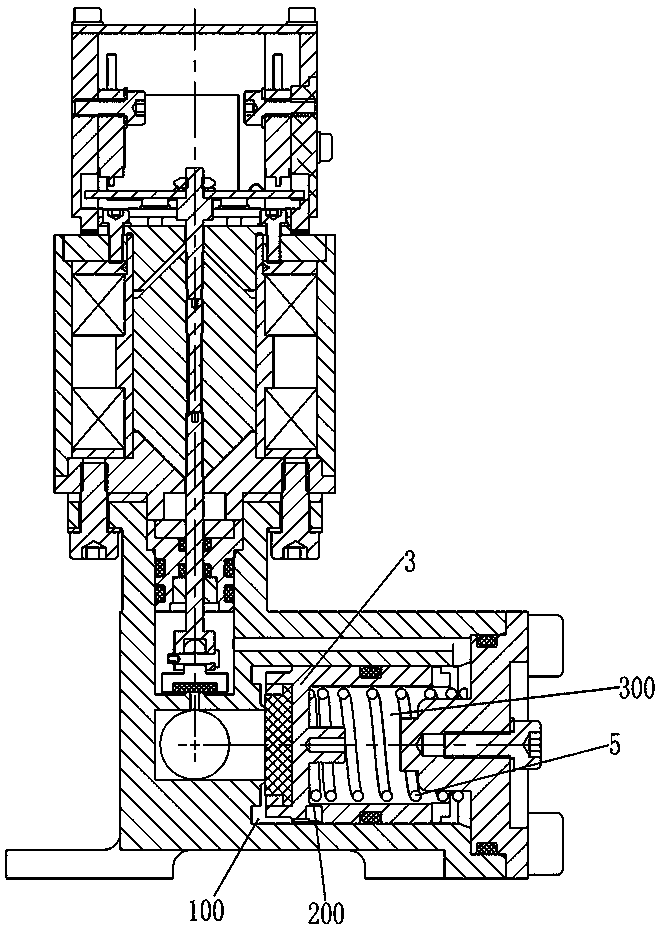

[0031] The specific embodiment of self-locking valve provided by the present invention, as Figure 1 to Figure 3 As shown, the self-locking valve in this embodiment includes a main valve and an electromagnet 8, and the electromagnet 8 is fixedly installed on the valve body of the main valve through a small washer B28 and a hexagonal cylinder head screw B29, and, in the armature 16, a The mounting hole extending in the direction of reciprocating movement of the armature 16, the valve stem 18 of the self-locking valve is fastened and assembled in the mounting hole through a threaded connection. Since the valve stem 18 forms an integral structure with the armature through a threaded connection, it can drive the armature 16 when it moves. The valve stem 18 acts synchronously, which ensures the consistent action between the armature 16 and the valve stem 18 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com