Shell assembly and watch

A shell assembly and shell technology, applied in the field of watches, can solve the problems of many parts, cracks in the front shell, and high cost, and achieve the effects of reducing manufacturing costs, avoiding micro-cracks, and extending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

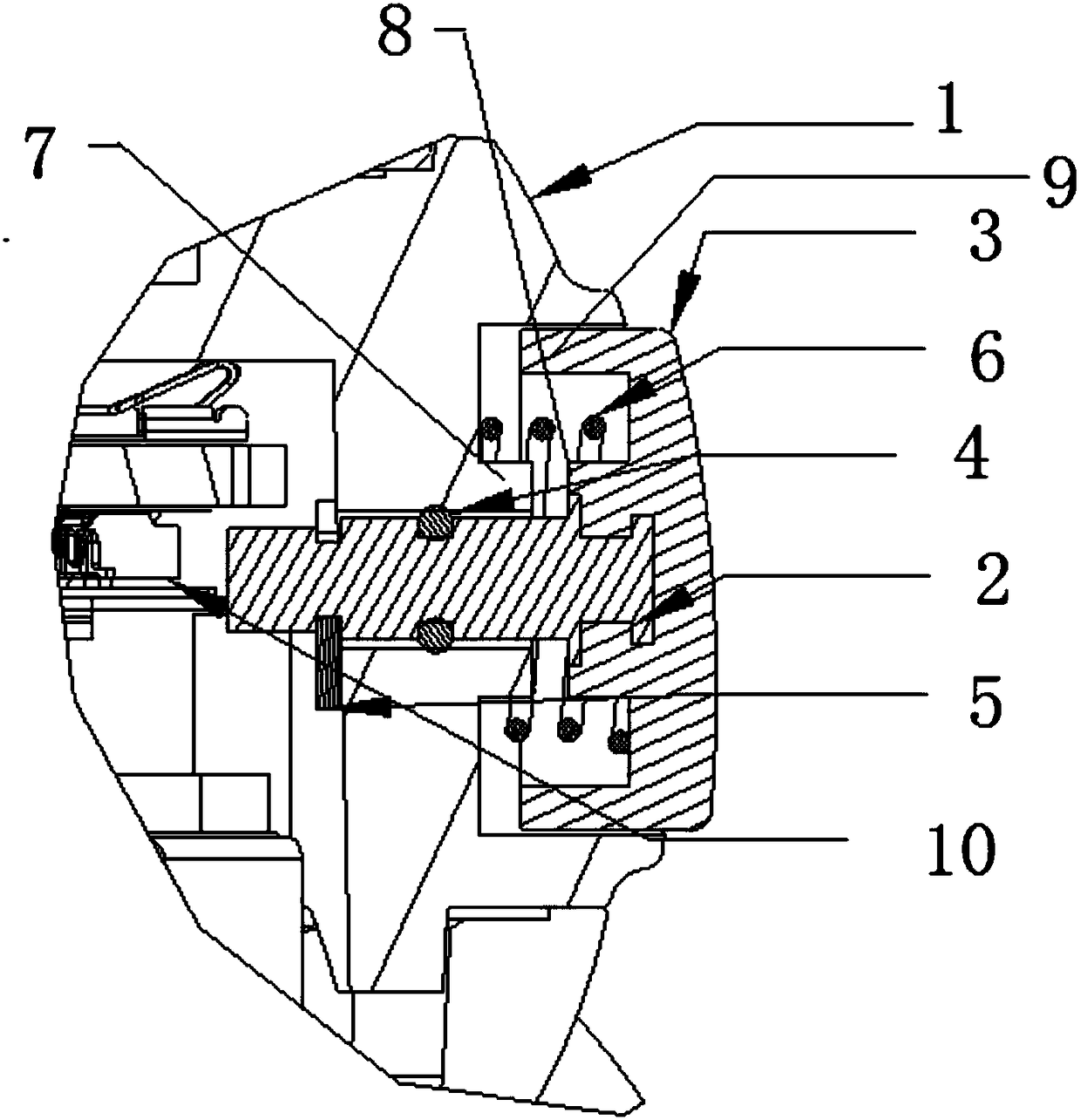

[0036] Such as figure 1 and figure 2 As shown, a housing assembly of the present invention includes

[0037] The housing 1 is formed with a through hole;

[0038] The top bar 2 is axially slidably arranged in the through hole, and one end of the top bar 2 on the outside of the housing 1 is equipped with a keycap 3, and one end on the inside of the housing 1 , for controlling the key switch 10 arranged in the housing 1;

[0039] a biasing member, the biasing force of which acts on the keycap 3 to reset the keycap 3 after being pressed by an external force;

[0040] A sealing element is arranged between the top bar 2 and the through hole.

[0041] Since the shell assembly cancels the setting of the stainless steel collar on the shell 1, the plastic shell 1 is no longer subject to the extrusion force of the collar, therefore, it is possible to avoid the generation of microcracks at the position where the button is installed on the shell 1, As a result, the yield rate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com