A preparation method of a low activation voltage resistive switch device

A technology for activating voltage and resistive switching devices, which is applied in the field of information storage, can solve the problems of unsatisfactory resistive storage characteristics, lack of resistive switching characteristics, and high defect formation energy, and achieve easy repeatable tests, low equipment requirements, and lower activation voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

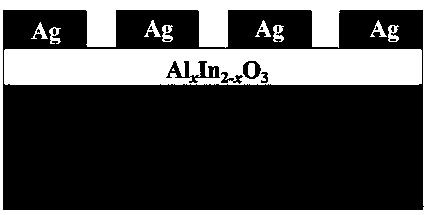

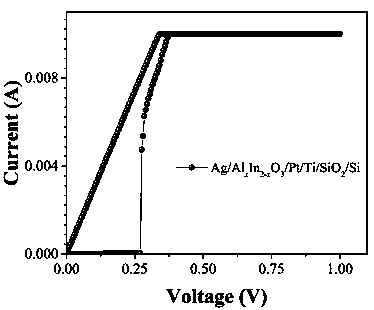

Embodiment 1

[0030] Pt / Ti / SiO with a length of 1 cm and a width of 1 cm 2 / Si substrates were cleaned with acetone, isopropanol, and deionized water, and dried for later use.

[0031] Prepare 0.2 mol / L indium nitrate aqueous solution and stir for 24 h before use.

[0032] A certain amount of solid aluminum nitrate was weighed and dissolved in 2.5 ml of hydrogen peroxide (30%) to prepare a 0.2 mol / L aluminum nitrate solution.

[0033] Add 111 μL of ammonia water and 75 μL of nitric acid to the aluminum nitrate solution, and stir for 24 h to obtain a mixed solution of aluminum nitrate.

[0034] Indium nitrate aqueous solution was spin-coated on Pt / Ti / SiO 2 / Si substrate, and then heated on a hot plate for 5 min. This process was repeated 4 times. The samples were then annealed in an annealing furnace at 180 °C for 1 h, and then allowed to cool naturally to room temperature.

[0035] After the sample was taken out, the aluminum nitrate mixed solution was spin-coated on the sample, and th...

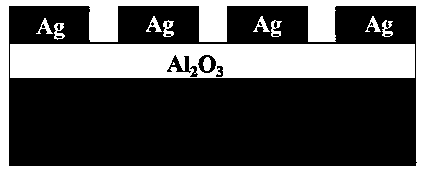

Embodiment 2

[0040] Pt / Ti / SiO with a length of 1 cm and a width of 1 cm 2 / Si substrates were cleaned with acetone, isopropanol, and deionized water, and dried for later use.

[0041] Prepare 0.22 mol / L indium nitrate aqueous solution and stir for 24 h before use.

[0042] A certain amount of solid aluminum nitrate was weighed and dissolved in 2.5 ml of hydrogen peroxide (30%) to prepare a 0.18 mol / L aluminum nitrate solution.

[0043]Add 111 μL of ammonia water and 75 μL of nitric acid to the aluminum nitrate solution, and stir for 24 h to obtain a mixed solution of aluminum nitrate.

[0044] Indium nitrate aqueous solution was spin-coated on Pt / Ti / SiO 2 / Si substrate, and then heated on a hot plate for 5 min. This process was repeated 4 times. The samples were then annealed in an annealing furnace at 150 °C for 1 h, and then allowed to cool down to room temperature naturally.

[0045] After the sample was taken out, the aluminum nitrate mixed solution was spin-coated on the sample, ...

Embodiment 3

[0049] Pt / Ti / SiO with a length of 1 cm and a width of 1 cm 2 / Si substrates were cleaned with acetone, isopropanol, and deionized water, and dried for later use.

[0050] Prepare 0.22 mol / L indium nitrate aqueous solution and stir for 24 h before use.

[0051] A certain amount of solid aluminum nitrate was weighed and dissolved in 2.5 ml of hydrogen peroxide (30%) to prepare a 0.2 mol / L aluminum nitrate solution.

[0052] Add 111 μL of ammonia water and 75 μL of nitric acid to the aluminum nitrate solution, and stir for 24 h to obtain a mixed solution of aluminum nitrate.

[0053] Indium nitrate aqueous solution was spin-coated on Pt / Ti / SiO 2 / Si substrate, and then heated on a hot plate for 5 min. This process was repeated 4 times. The samples were then annealed in an annealing furnace at 180 °C for 1 h, and then allowed to cool naturally to room temperature.

[0054] After the sample was taken out, the aluminum nitrate mixed solution was spin-coated on the sample, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com