Method and device for manufacturing fuel cell membrane electrode

A technology of fuel cell membrane and manufacturing method, which is applied to fuel cells, battery electrodes, circuits, etc., can solve problems such as surface A coating damage, and achieve the effects of improving production efficiency and reducing production scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

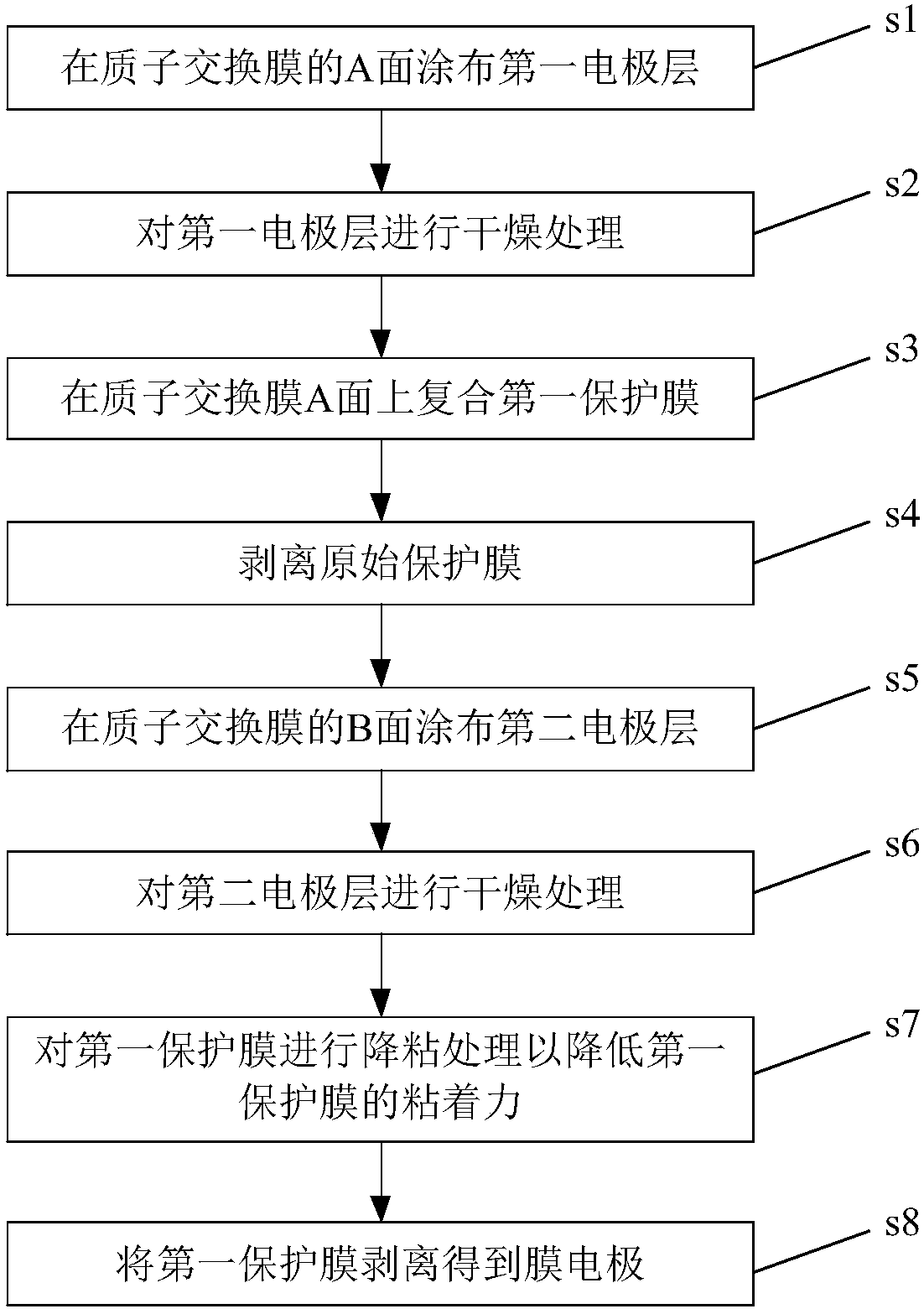

[0037] This embodiment provides a method for manufacturing a fuel cell membrane electrode, and the fuel cell is described by taking a proton exchange membrane fuel cell as an example, as follows figure 1 , including the following steps:

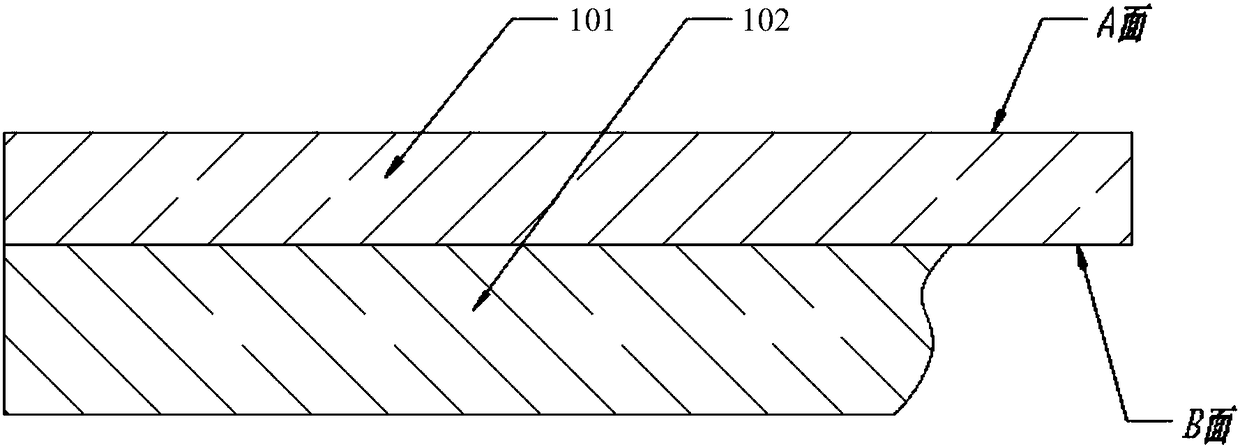

[0038] s1: Coating the first electrode layer on the A side of the proton exchange membrane. like figure 1 As shown, before coating the first electrode layer, the proton exchange membrane is in the original state, with a layer of original protective film 102, the side of the proton exchange membrane 101 that is not protected by the original protective film 102 is called A side, which is protected The surface is called the B surface; in other words, the A surface of the proton exchange membrane 101 before the MEA is not provided with an original protective film, and the B surface is provided with an original protective film 102 . The first electrode layer may be a catalyst anode layer or a catalyst cathode layer, and this embodiment uses the ...

Embodiment 2

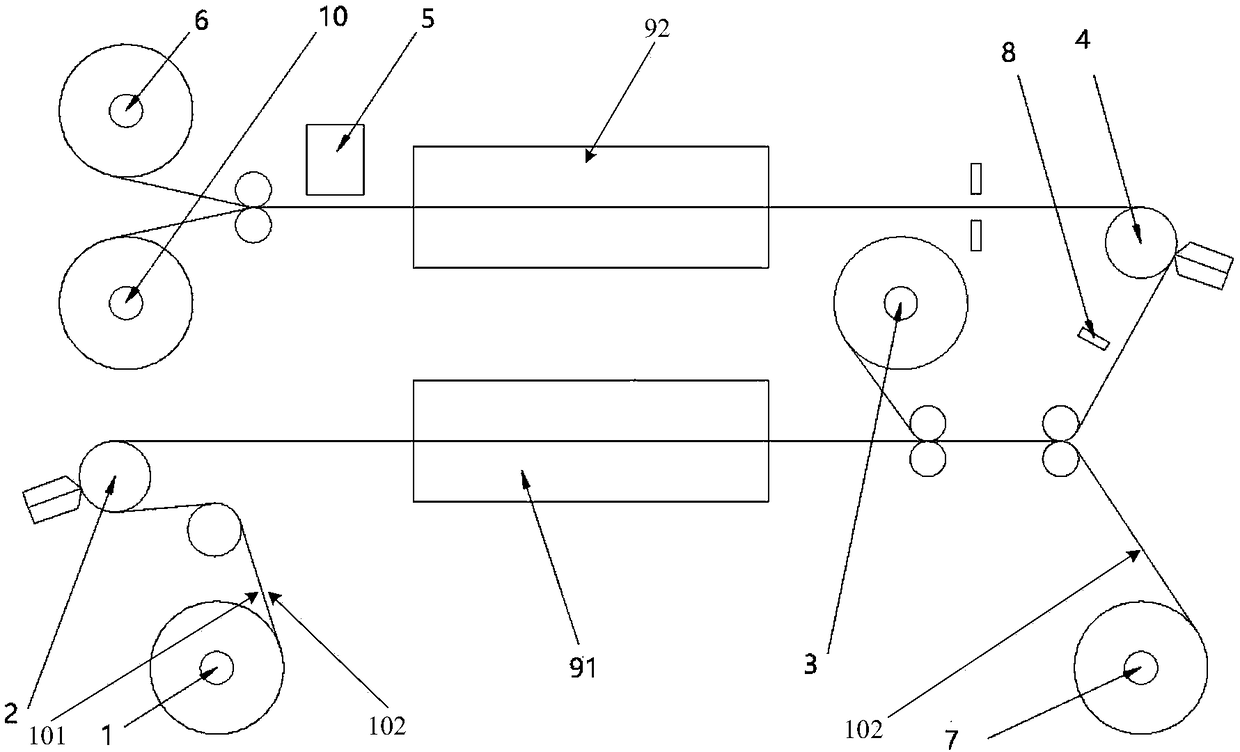

[0049] This embodiment provides a fuel cell membrane electrode manufacturing equipment, such as image 3 ,include:

[0050] The first unwinding device 1 is used to release the proton exchange membrane in the way of unwinding and discharging; the proton exchange membrane is controlled by constant tension to enter the first coating device 2 at a preset speed. like figure 1 As shown, before coating the first electrode layer, the proton exchange membrane is in the original state, with a layer of original protective film 102, the side of the proton exchange membrane 101 that is not protected by the original protective film 102 is called A side, which is protected The side is called the B side.

[0051] The first coating device 2 is arranged on the downstream of the first unwinding device 1, and is used to coat the first electrode layer on the A side of the proton exchange membrane released by the first unwinding device 1; the first electrode layer can be The catalyst anode layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com