Gap eliminating part

A gap and body technology, applied in the field of gap elimination parts, can solve the problems of different shapes and sizes, weak strength, loose matching structure, etc., to achieve the effect of strong gap elimination ability, lower production cost, and tight fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0039] The gap eliminating part provided by the present invention is made of elastic material, which can be elastic metal material or elastic plastic, etc. In addition, preferably, for the convenience of production, the gap eliminating part is made of the same material as a whole.

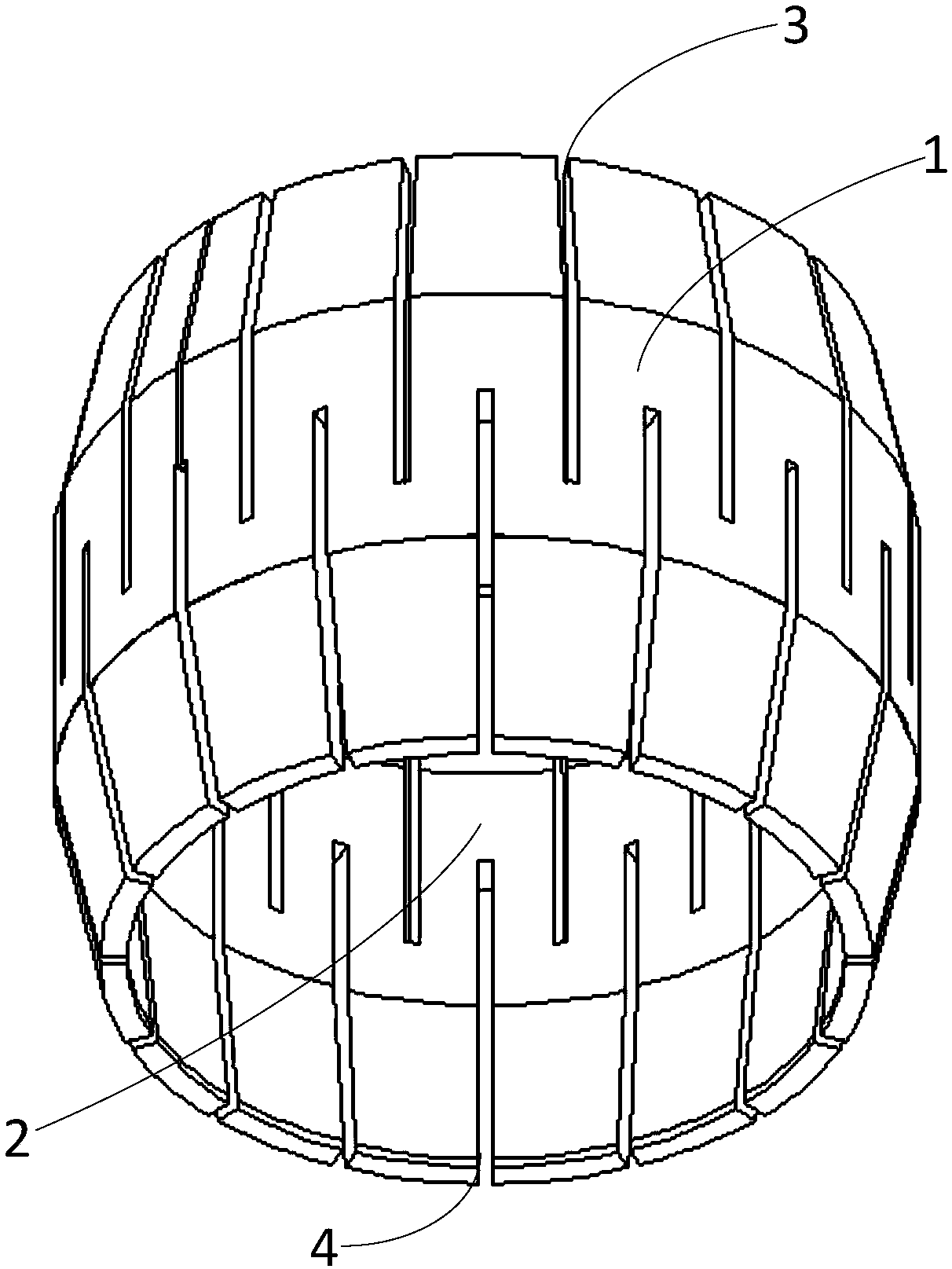

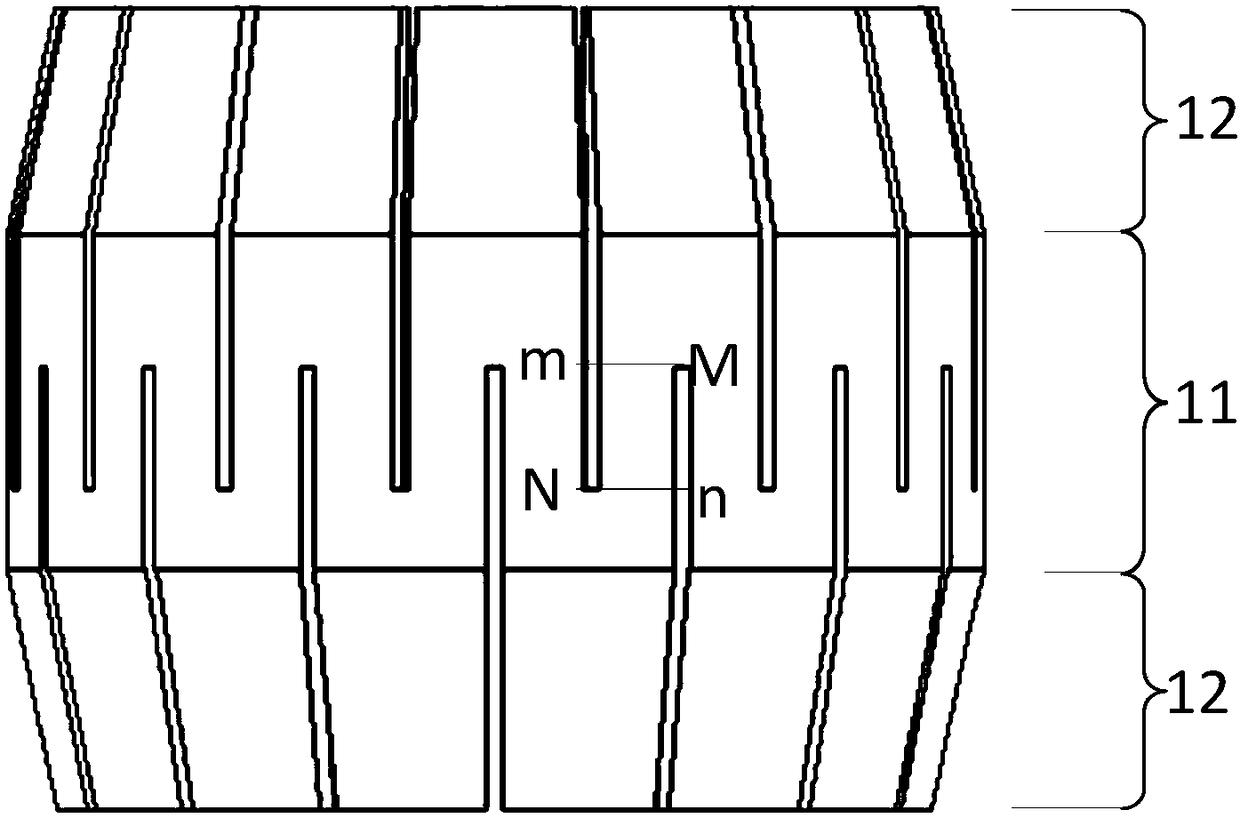

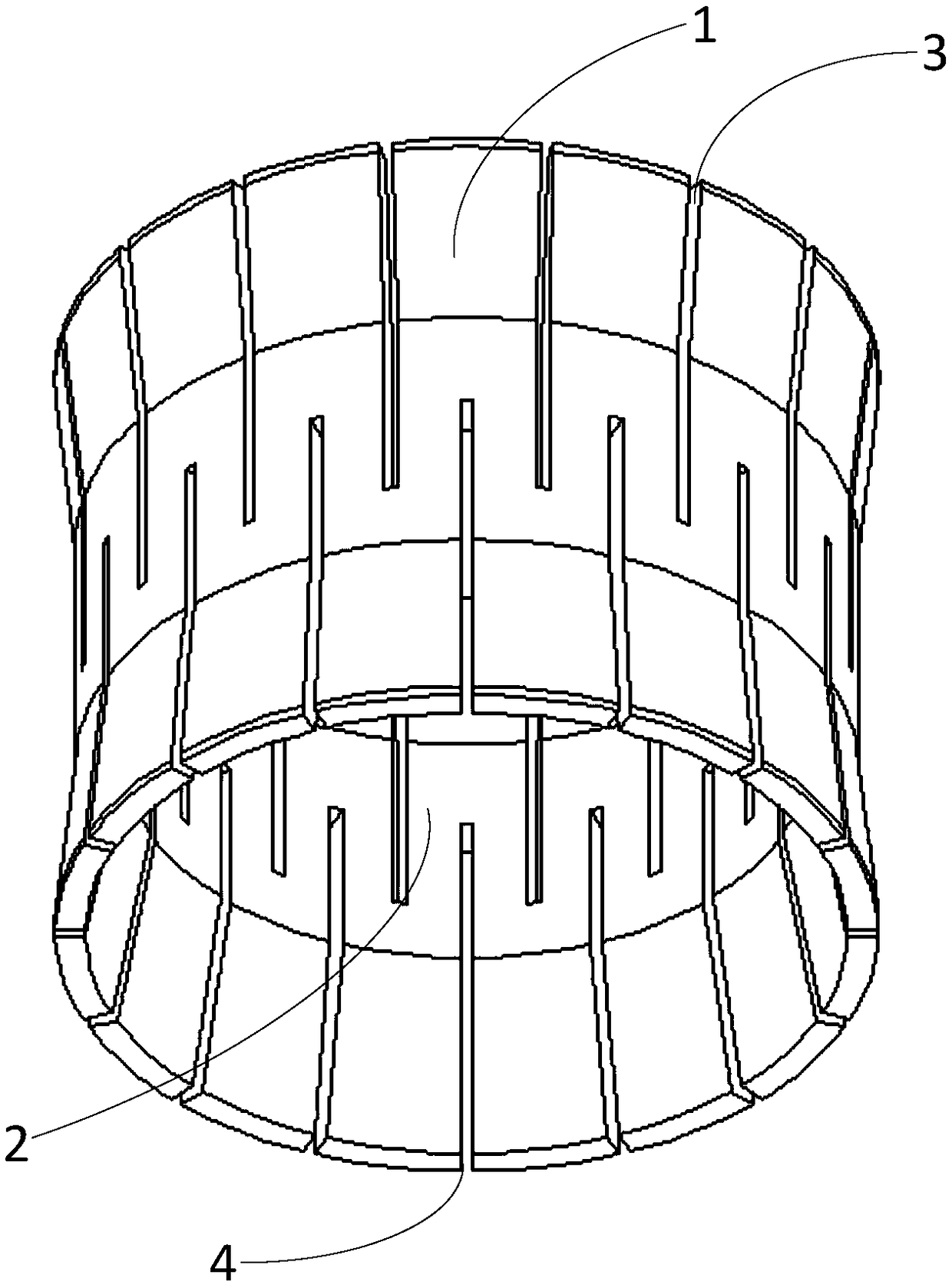

[0040] Such as Figure 1 to Figure 5 As shown, the gap eliminating part provided by the present invention is used for tight fitting connection of holes and shafts, and the gap eliminating part includes: a body 1; Through holes 2; the first gap bridging seam 3 and the second gap bridging seam 4 alternately arranged on the side wall of the body 1; wherein, the first gap bridging seam 3 and the second gap bridging seam 4 start from the two ends of the body 1 respectively, And extend along the axial direction; in addition, the first gap bridging seam 3 and the second gap bridging seam 4 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com