Fault-tolerant modular permanent magnet auxiliary synchronous reluctance motor

An auxiliary synchronous, reluctance motor technology, applied in the direction of motor, magnetic circuit, electromechanical device, etc., can solve the problems of safety threats to people in the electric vehicle, the motor can not work normally, no fault-tolerant performance, etc. Mass production, easy assembly, reduced effect of magnetic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

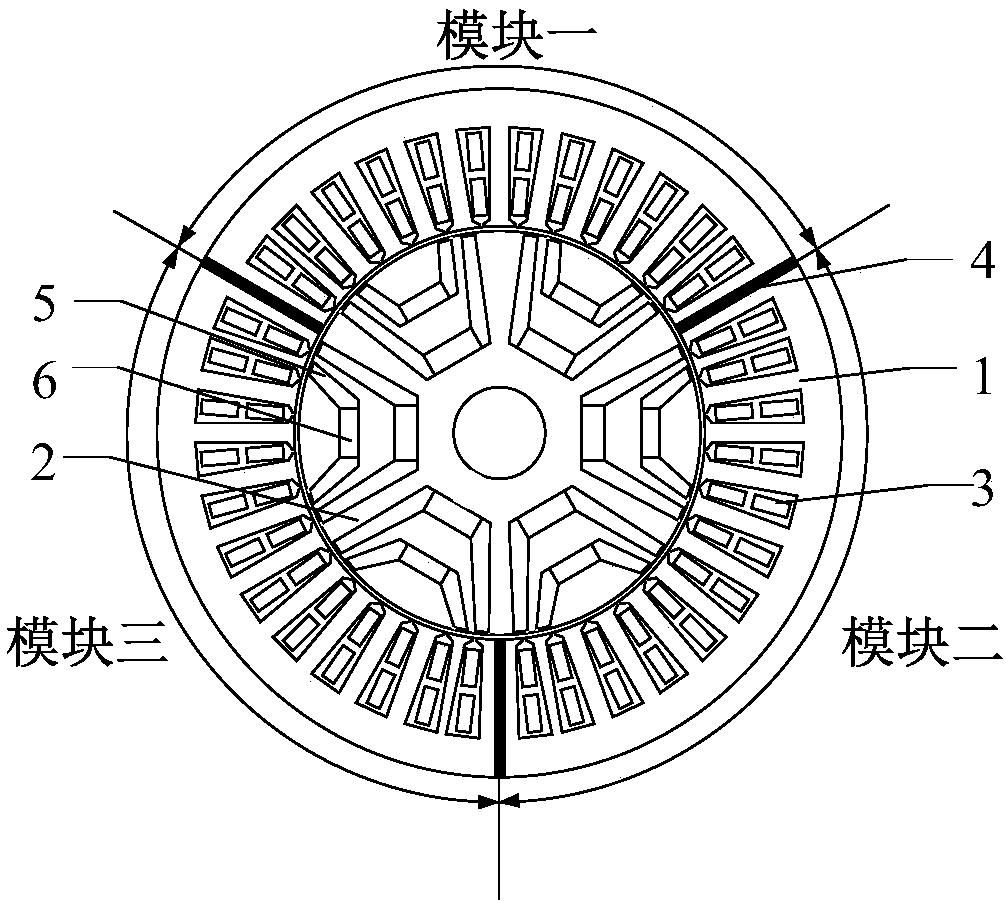

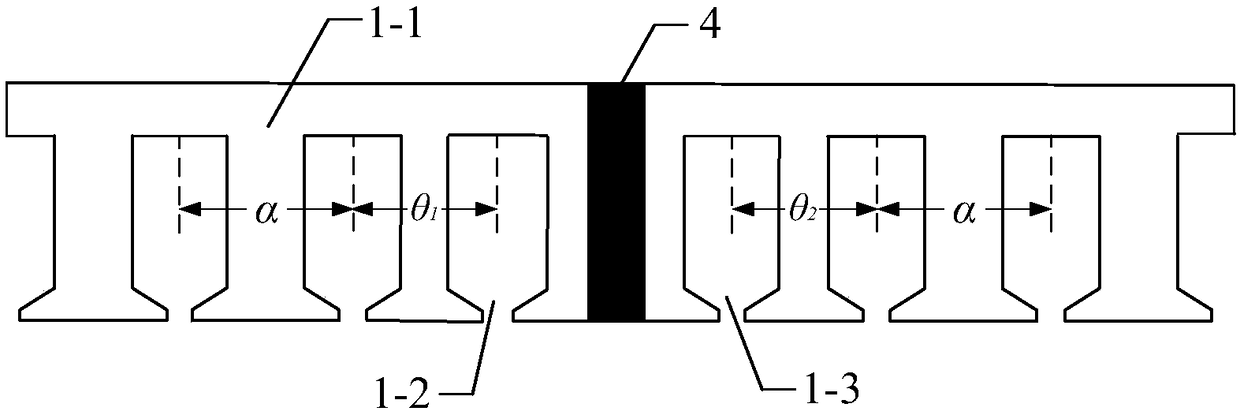

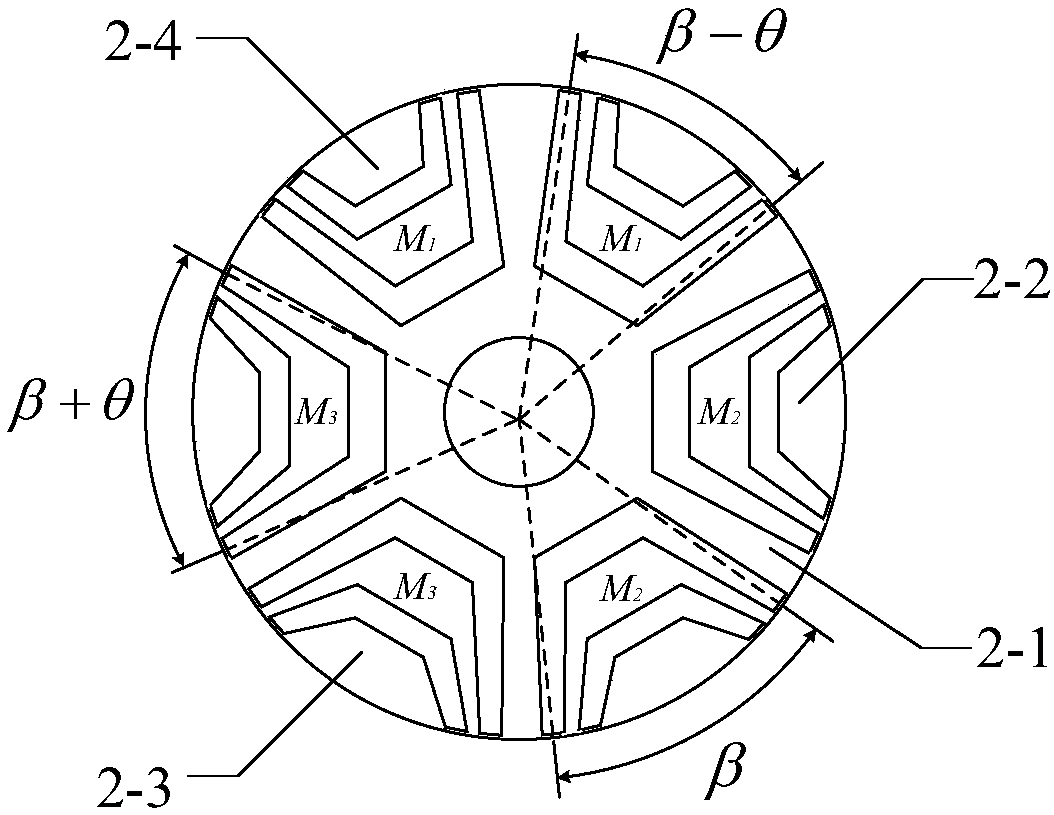

[0031] Refer to the attached figure 1 , the structural features and beneficial effects of the modular permanent magnet assisted synchronous reluctance motor proposed by the present invention are described in detail. like figure 1 As shown, including modular stator 1 and rotor 2. combine figure 2 , the modular stator includes a stator core 1-1, an armature winding 3, a non-magnetic body 4 and a plurality of tooth and slot structures along the circumferential direction. The slots 1 - 2 and 1 - 3 closest to both sides of the shown non-magnetic body are respectively offset along the circumferential direction away from the non-magnetic body 4 . combine image 3 , the rotor includes a rotor core 2-1, a magnetic barrier 5 and a permanent magnet 6, the permanent magnet is placed in the magnetic barrier structure, and the N poles and S poles of adjacent permanent magnets are arranged alternately. Figure 4 The winding connections used for each modular unit of the stator are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com