A Highly Fault Tolerant Modular Winding Design Method for Permanent Magnet Assisted Synchronous Reluctance Motor

A technology for assisting synchronous and reluctance motors, applied to the shape/style/structure of electric components, winding conductors, magnetic circuits, etc. The effect of magnetic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

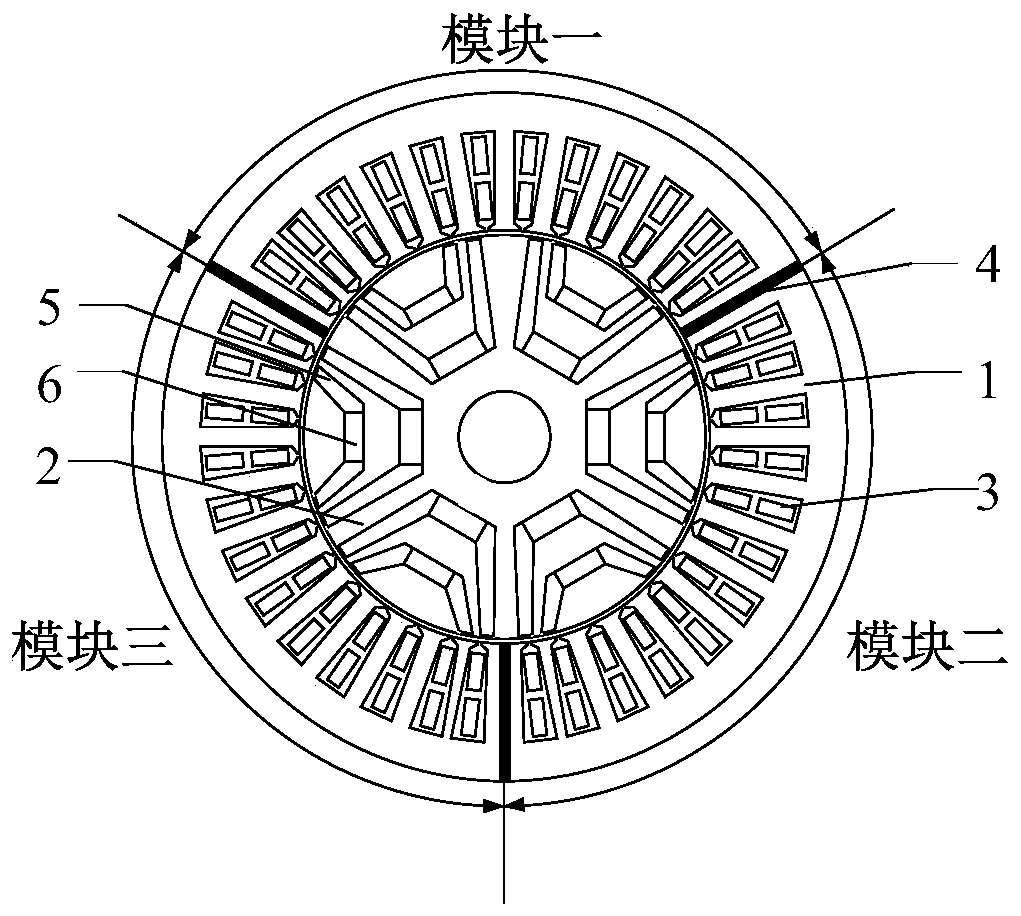

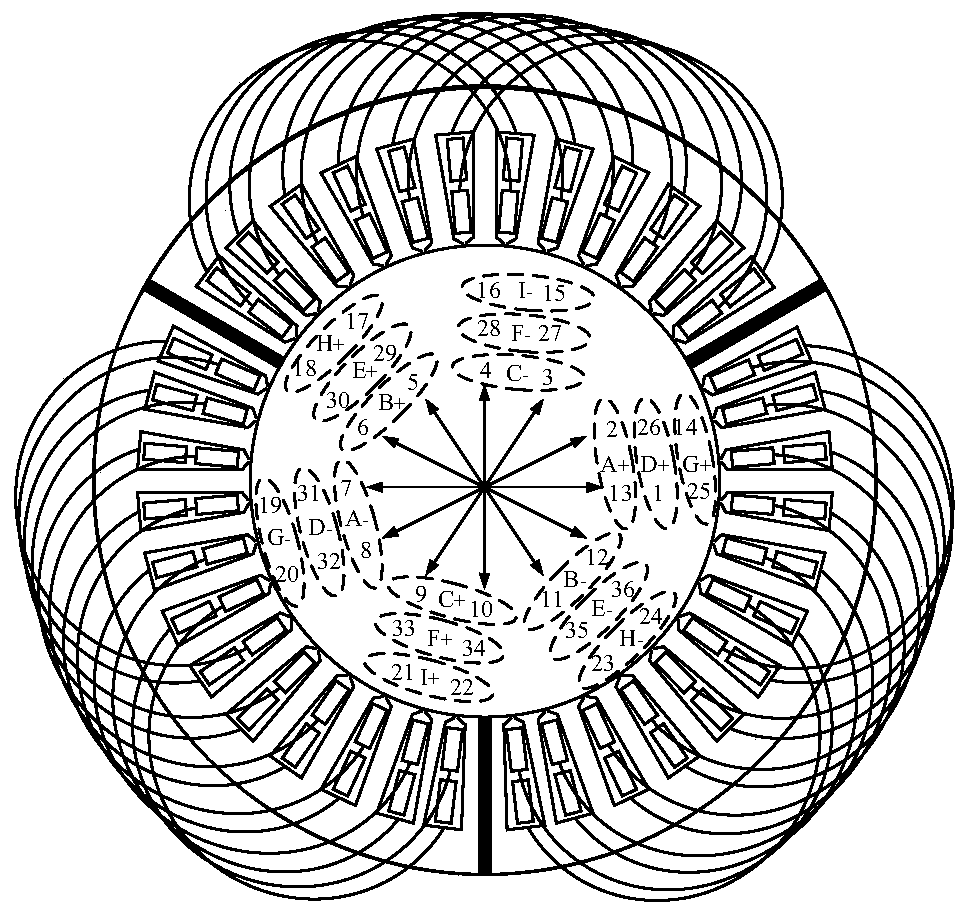

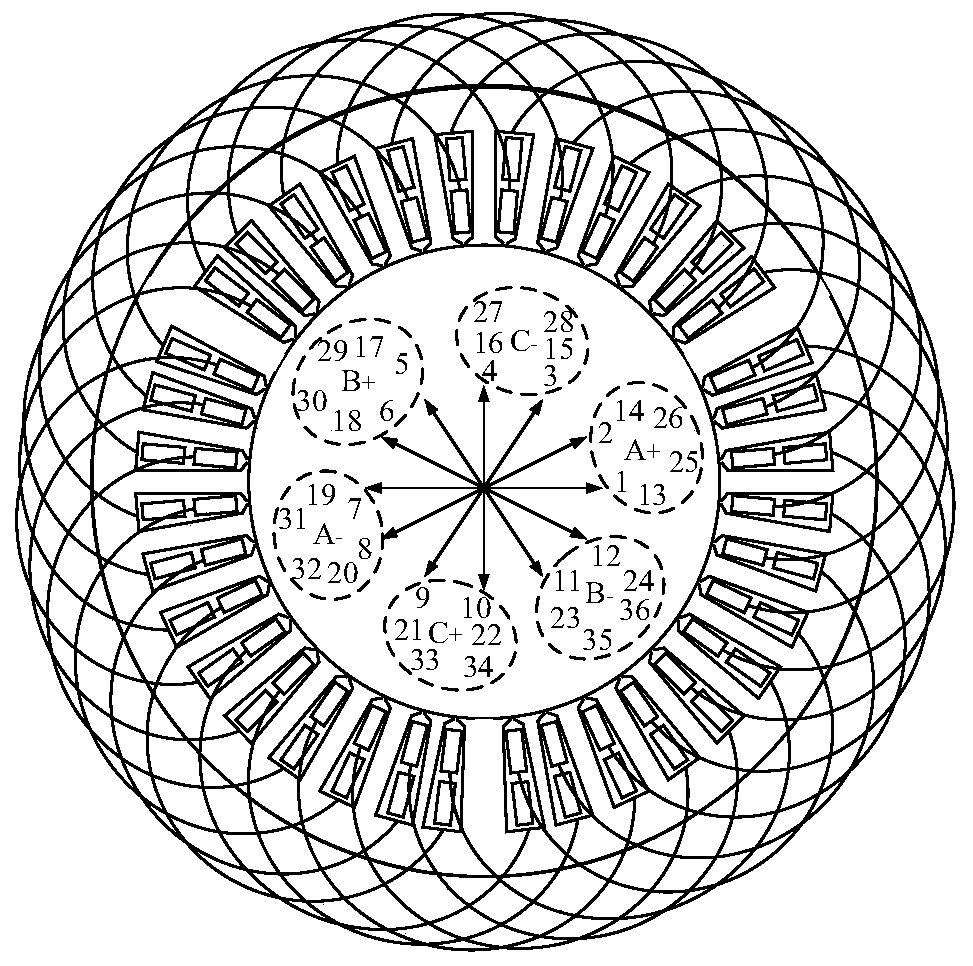

[0032] Referring to the accompanying drawings, a detailed description will be given to a highly fault-tolerant PMa-SynR motor modular winding design method proposed by the present invention. figure 1 It is an embodiment of PMa-SynR of the present invention. Such as figure 1 As shown, the PMa-SynR motor includes a modular stator 1 , a rotor 2 , an armature winding 3 , a non-magnetic body 4 , a magnetic barrier 5 and a permanent magnet 6 . The PMa-SynR motor stator in the embodiment of the present invention is composed of 3 modules, and each module is connected by 3-phase distributed windings. Such as figure 2 As shown, the windings in the module adopt a left-right relative distribution form, which can realize the independence of the modular windings, and is conducive to improving the fault-tolerant performance of the motor. The PMa-SynR motor rotor in the embodiment of the present invention has a 2-layer U-shaped magnetic barrier structure.

[0033] When designing the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com