Full-passing house type grain store

A roof and warehouse technology, applied in the field of storage engineering, can solve the problems of high facility investment and maintenance management costs, reduce the overall cost and operation management costs, improve operation management efficiency and economic benefits, and improve social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

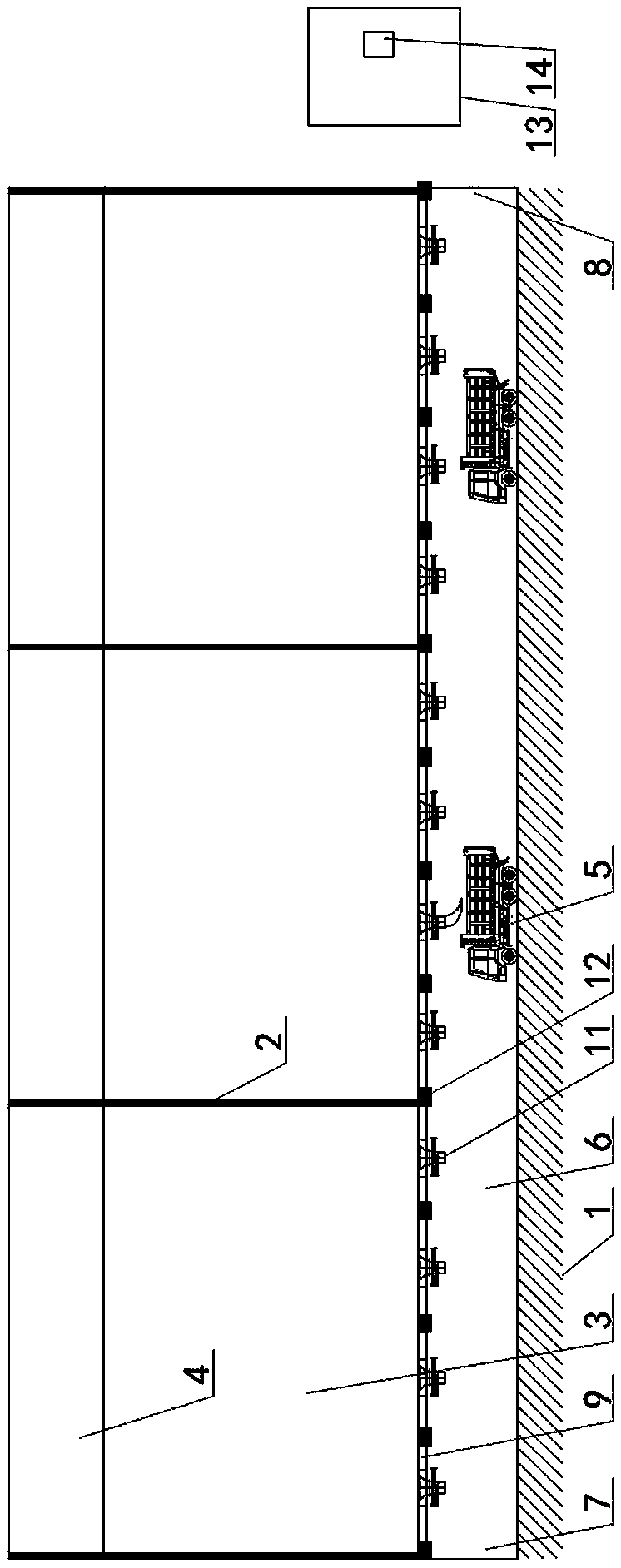

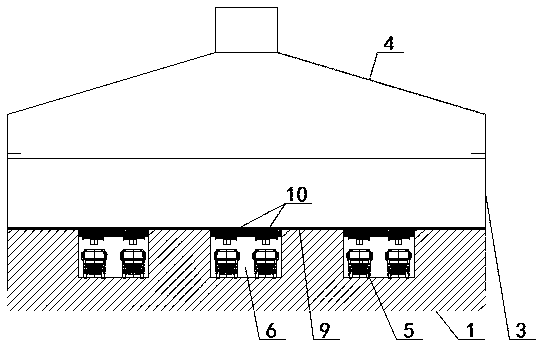

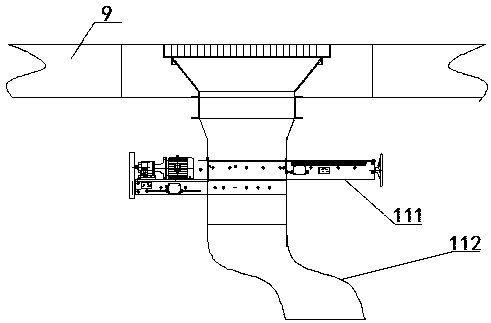

[0047] Such as figure 1 , figure 2 and image 3 As shown, a full-through room type warehouse includes a ground 1, an inner wall body 2, an outer wall body 3 and a roof 4, and the inner wall body 2 divides the room type warehouse into several small rooms Under the ground 1, several distribution tunnels 6 for passing vehicles 5 are dug along the length direction of the room type warehouse. The left end of the distribution tunnel 6 is a vehicle exit 7, and the right end of the distribution tunnel 6 is a vehicle exit. Entrance 8, the top of the distribution tunnel 6 is provided with a load-bearing roof 9 that is flush with the upper part of the ground 1, and several rows of vehicle distribution facilities 10 are arranged on the load-bearing roof 9 along the length direction of the distribution tunnel 6. Each row Each of the vehicle distribution facilities 10 includes a plurality of distribution facility units 11 , and each of the distribution facility units 11 includes a gate v...

Embodiment 2

[0060] Such as figure 1 , figure 2 and Figure 4 As shown, a full-through room type warehouse includes a ground 1, an inner wall body 2, an outer wall body 3 and a roof 4, and the inner wall body 2 divides the room type warehouse into several small rooms Under the ground 1, several distribution tunnels 6 for passing vehicles 5 are dug along the length direction of the room type warehouse. The left end of the distribution tunnel 6 is a vehicle exit 7, and the right end of the distribution tunnel 6 is a vehicle exit. Entrance 8, the top of the distribution tunnel 6 is provided with a load-bearing roof 9 that is flush with the upper part of the ground 1, and several rows of vehicle distribution facilities 10 are arranged on the load-bearing roof 9 along the length direction of the distribution tunnel 6. Each row Each of the vehicle distribution facilities 10 includes a plurality of distribution facility units 11 , and each of the distribution facility units 11 includes a gate ...

Embodiment 3

[0071] Such as Figure 5 As shown, the difference between it and Embodiment 2 is that a row of infrared position sensors 18 for monitoring the position of the vehicle 5 is arranged on both sides of the distribution tunnel 6, and the infrared position sensors 18 and the controller 14 signal connect.

[0072] In this embodiment, in order to more accurately monitor the position of the vehicle staying on the distribution corridor, a row of infrared position sensors for detecting the position of the vehicle is arranged on both sides of the distribution tunnel, and the infrared position sensors are connected to the controller for signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com