Spoon

The technology of a spoon and a body is applied in the field of improvement of spoons, which can solve the problems of easy softening, poor anti-scalding effect, and insufficient safety and hygiene of the contact between silica gel and food, and achieves good anti-scalding performance, safe and hygienic anti-scalding effect, and anti-scalding effect. good hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

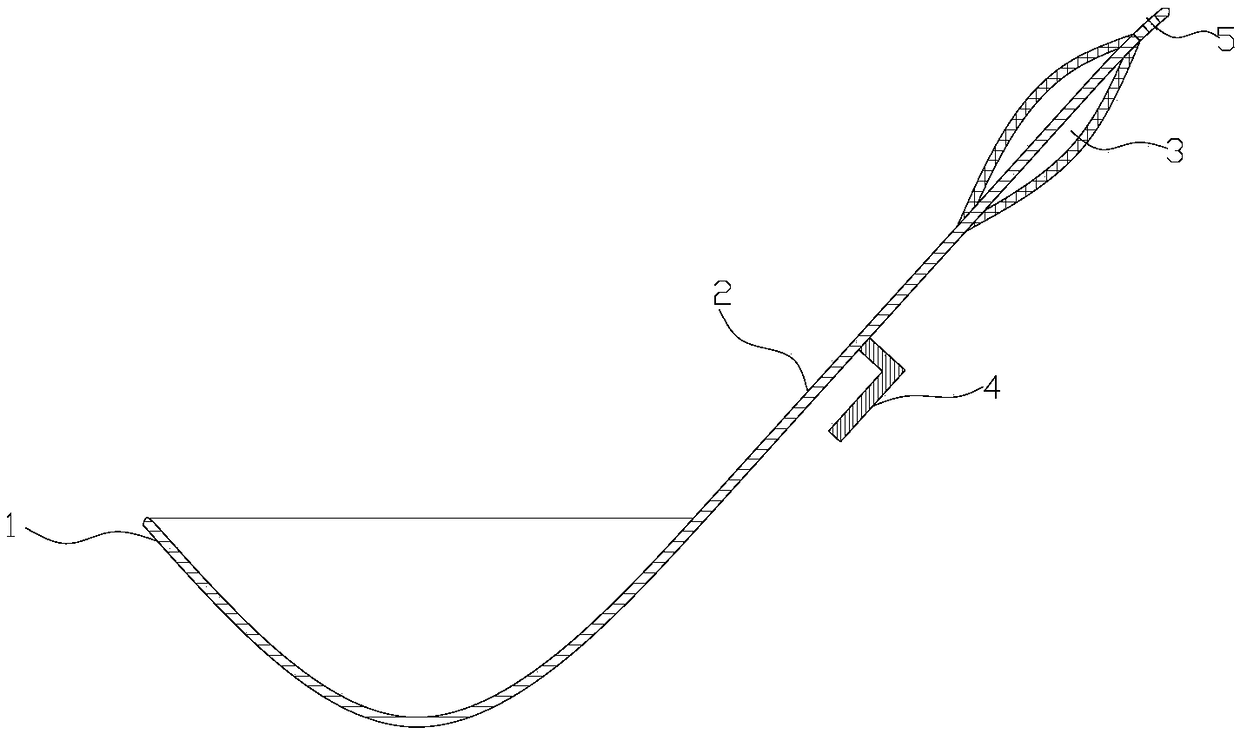

[0012] The present invention as figure 1 As shown, a spoon comprises a hemispherical stainless steel spoon body 1 and a stainless steel elongated spoon handle 2 on one side of the spoon body, the head end of the spoon handle 2 is connected to the spoon body 1 connected, the end of the spoon handle 2 is provided with a silica gel layer, and a cavity 3 is provided between the silica gel layer and the spoon handle 2; a partition is provided inside the cavity 3, and the partition divides the The cavity is divided into several empty chambers, which are filled with liquid.

[0013] On the one hand, the baffle can increase the strength of the cavity, avoid excessive sag of the cavity during use, and prevent the inner wall of the cavity from directly contacting the handle of the spoon, which will cause the cavity to melt and prolong the service life of the cavity.

[0014] The cavity is filled with a liquid with a high specific heat, so that the heat transmitted from the handle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com