Method for operating a dust collector with a permanent filter

A technology for vacuum cleaners and filters, which is applied to vacuum cleaners, suction filters, household appliances, etc. It can solve the problems of limiting the regeneration effect, achieve the effect of improving the regeneration effect and increasing the power of the regeneration fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

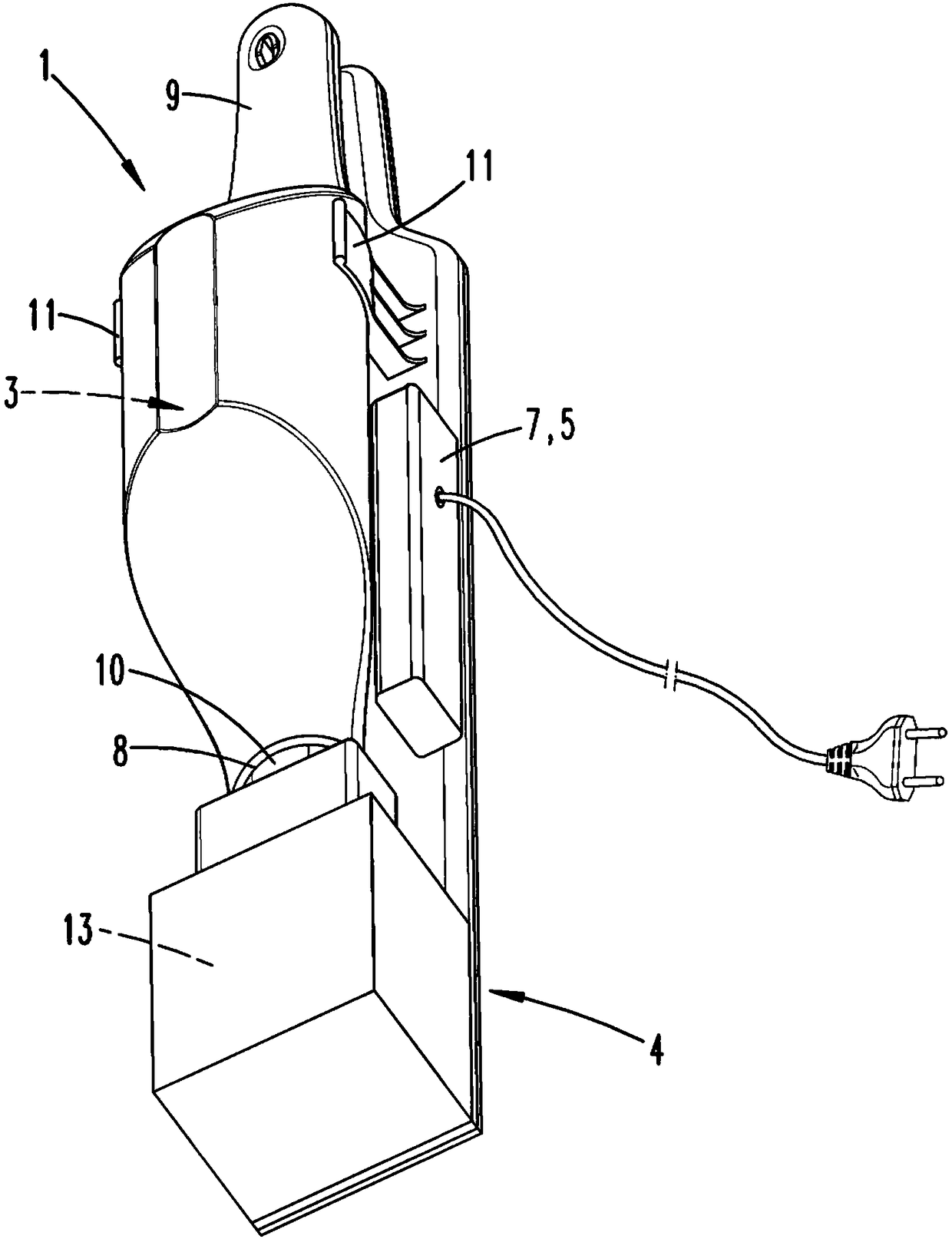

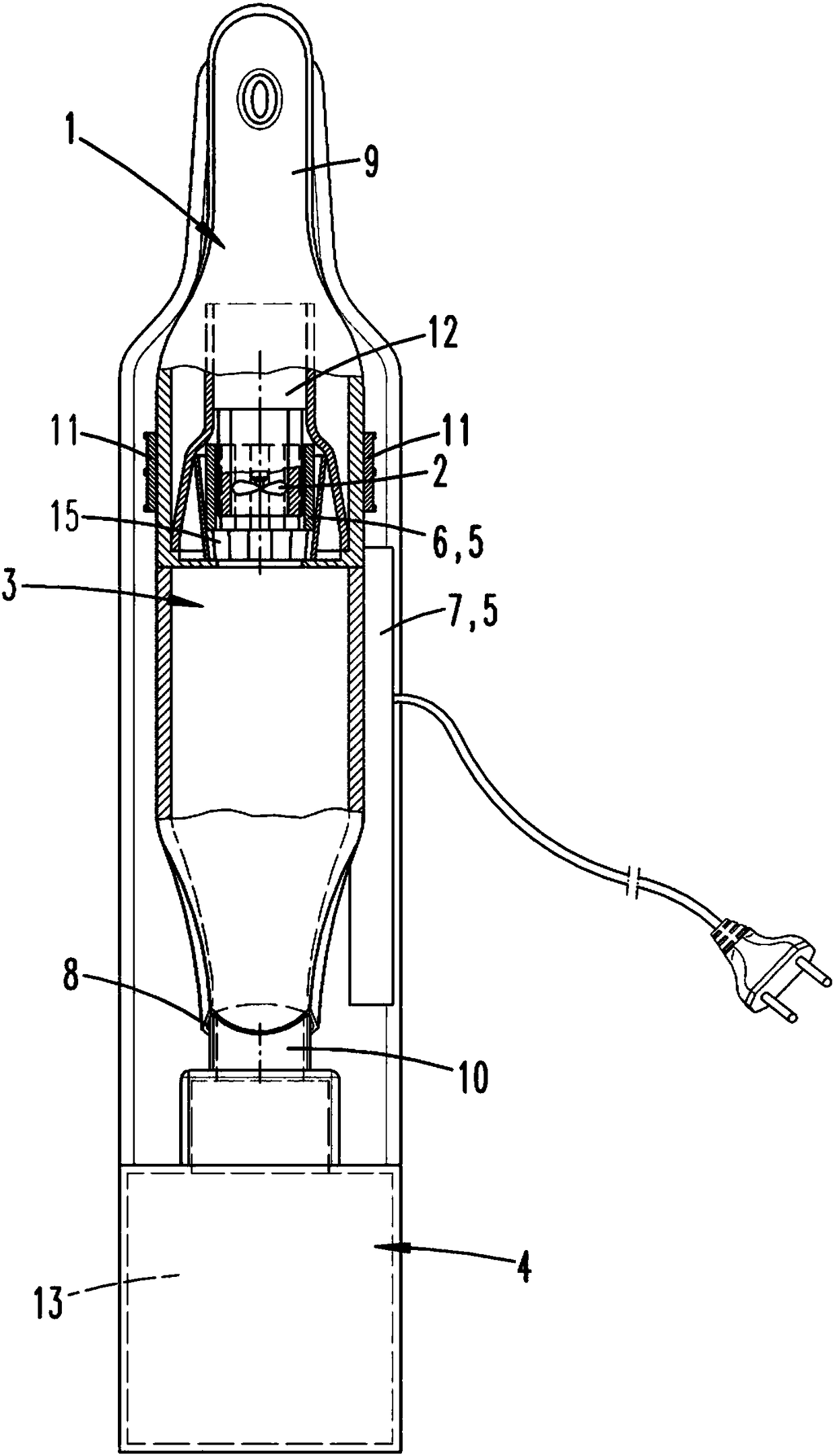

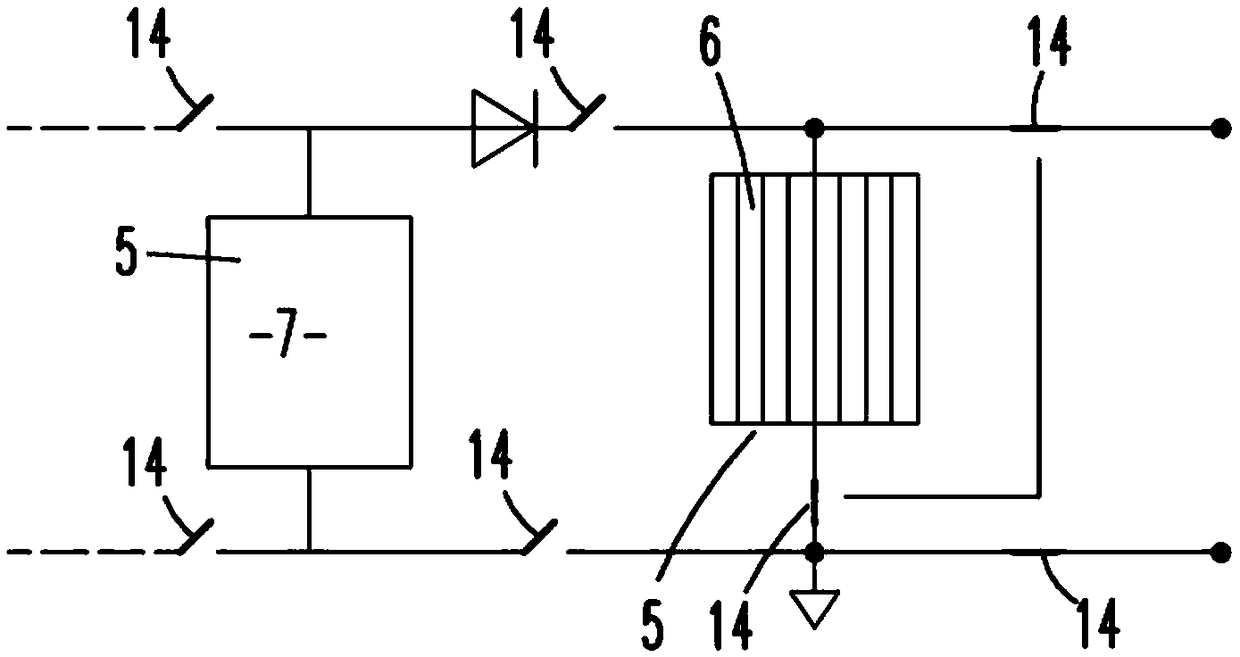

[0024] figure 1 and figure 2A system composed of a vacuum cleaner 1 and a base station 4 is shown. The vacuum cleaner 1 is designed here as a hand-held battery vacuum cleaner with a handle 9 on which the user can hold the vacuum cleaner 1 during operation on the surface to be cleaned. Suction material, that is to say dust and dirt, can be sucked into vacuum cleaner 1 via suction nozzle 8 . Vacuum cleaner 1 has fan 2 ( figure 1 Not shown in ) and filter chamber 3 with permanent filter 15. During operation, the sucked-in fluid reaches the filter chamber 3 due to the suction force of the fan 2 and is trapped there, while only cleaned air can pass through the permanent filter 15 and reach the fan 2 . The voltage required for the working operation, ie the operation of the fan 2 or its motor 12 , is provided by the power supply 5 of the vacuum cleaner 1 . The power source 5 is here an accumulator 6 which can be recharged by means of a power supply unit 7 of the base station 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com