Bamboo batten discharging and collection device of bamboo breaking machine

A collection device and bamboo strip technology, which is applied in mechanical equipment, forming/shaping machines, sugarcane machining, etc., can solve the problems of increased labor cost consumption and difficulty in ordering bamboo strips, and achieve the effect of saving labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

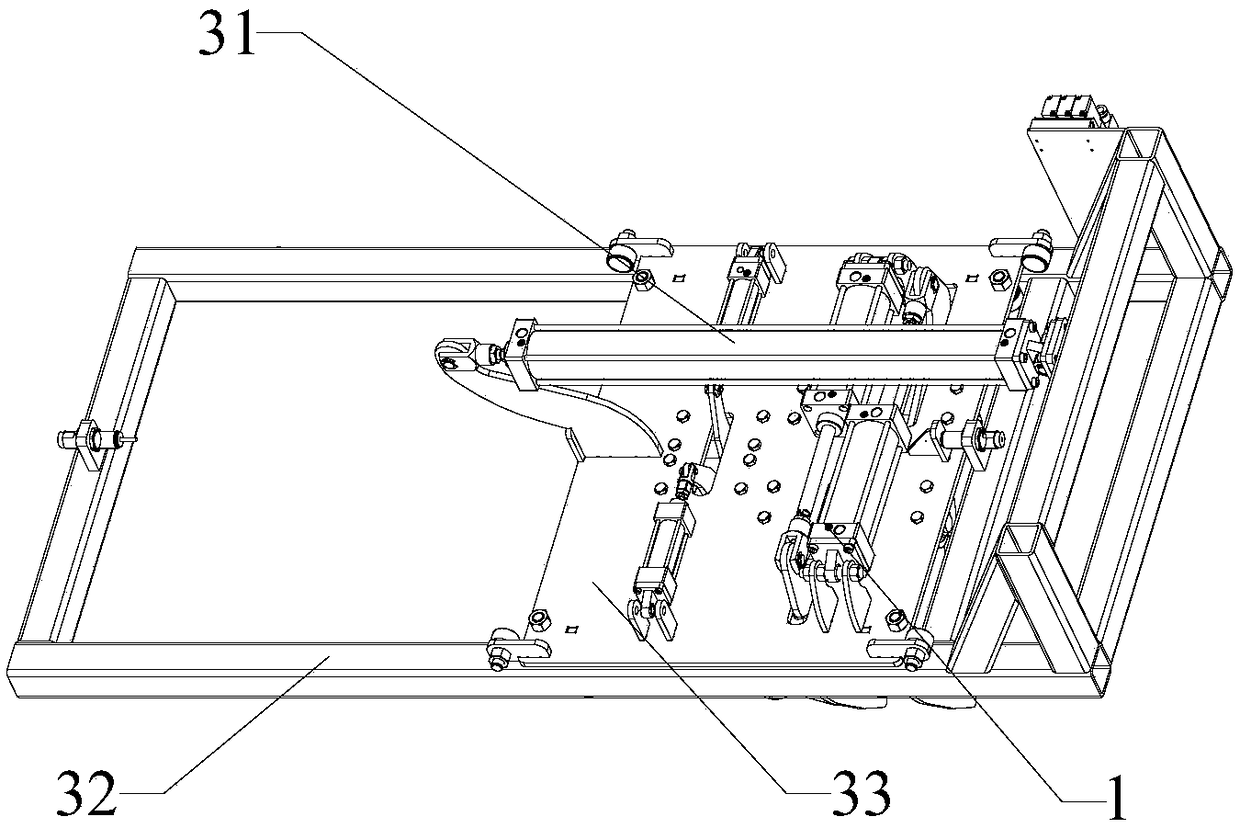

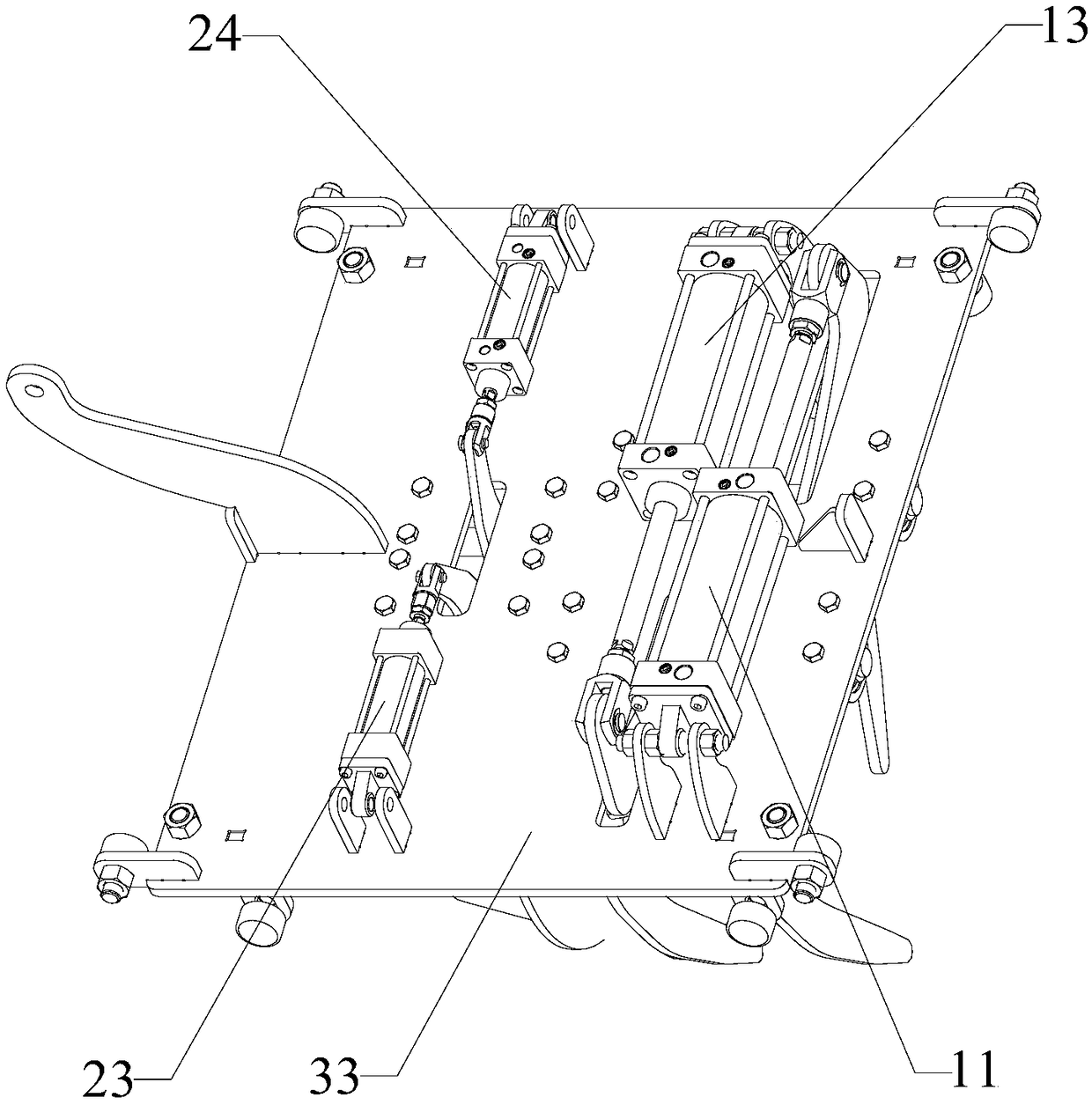

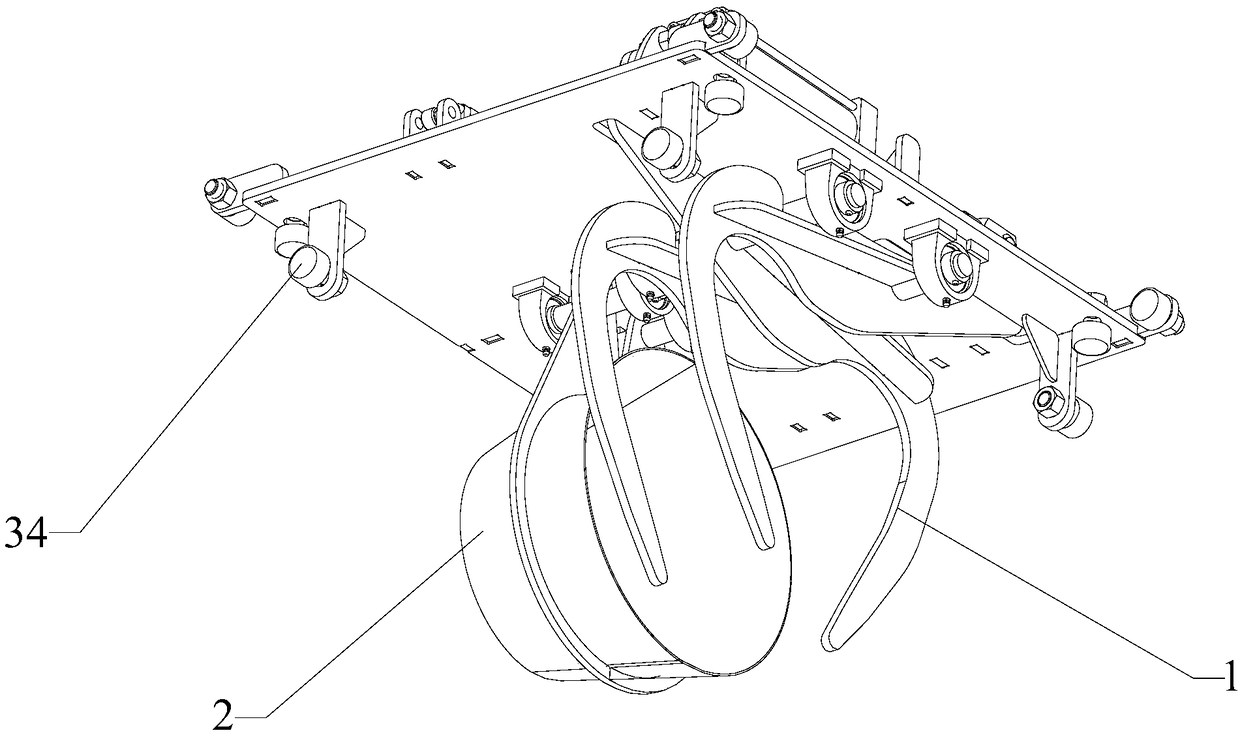

[0039] A bamboo strip output collection device for a bamboo breaking machine, comprising a claw mechanism and a cutter head 4 arranged on a base; the claw mechanism includes a mobile platform 3 arranged along the output direction of bamboo tubes, and a claw mechanism connected to the lower part of the mobile platform 1 and guide cylinder 2; the jaw mechanism 1 is located between the guide cylinder 2 and the cutter head 4; the guide cylinder 2 includes a driving device and a hollow circular platform tube, and the larger circular opening of the circular platform tube faces the jaws Mechanism, the smaller circular opening of the circular platform tube is towards the output end of the bamboo tube; the circular platform tube is composed of a first semicircular platform tube 21 and a second semicircular platform tube 22 which are arranged symmetrically to each other, and the first semicircular platform tube 21 Connected to the driving device, the second semi-circular table cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com