Straddle-type monorail substitute beam single-crossover turnout equipment

A straddle-type monorail and turnout technology, which is applied to mechanical equipment for operating turnouts or line circuit breakers, locking mechanisms for turnouts, railway car body parts, etc. Fewer power points, simple interface form, improved reliability and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

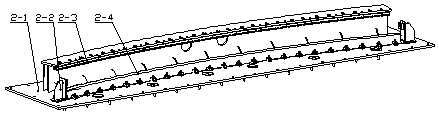

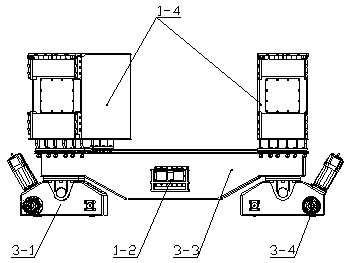

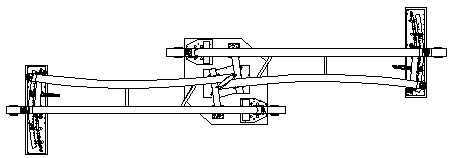

[0016] Embodiment 1: with reference to attached Figure 1-5 . A straddle-type monorail replacement beam single-crossing turnout equipment, the turnout is installed on the foundation floor 1-1 as a whole, and two supporting trolleys 1-5 are respectively used to support the front curve turnout beam and the rear curve at the center of rotation of the beam replacement turnout The turnout beam, and the curve connecting beam 1-7 is between the front curve turnout beam and the rear curve turnout beam, and the curve connection beam 1-7 is composed of the front curve turnout beam and the rear curve turnout beam, and the curve curve connection beam 1-7 is installed on a fixed On the supporting pier, the fixed supporting pier is used to connect the front curved turnout beam and the rear curved turnout beam, and two supporting trolleys 2 1-6 are respectively used to support the straight turnout beam 1-4 at the center of rotation of the beam replacement turnout, The driving running device...

Embodiment 2

[0027] Embodiment 2: with reference to attached Figure 6 and 7 . The detailed working method of the turnout: the turnout is installed on the foundation floor 1-1 as a whole, the supporting trolley 1-5 and the supporting trolley 2 1-6 are used to support the straight and curved turnout beams 1-4, and walk on the foundation floor ; The drive running device 1-3 provides power for the turnout switch and supports the turnout beam 1-4, and the drive gear 3-4 meshes with the rack 2-3 to push the switch drive running device 1-3 to move, thereby dragging the turnout beam 1-4 Rotate a certain angle along the predetermined position, and connect with the corresponding track beam to form a branch road, that is, to realize Figure 6 The turnout is open to traffic in a straight line, or Figure 7 Turnout curve opening state; connecting stack beams 1-7 are installed on fixed support piers and fixed on the foundation for connecting curved turnout beams. The locking device 1-2 adopts a bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com